Anti-adhesive mucous layer on the surface of an electric knife

A technology of mucosal layer and anti-adhesive layer, which is applied in the direction of layered products, metal layered products, parts of surgical instruments, etc., and can solve the problems of poor anti-adhesive effect of small intestine tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

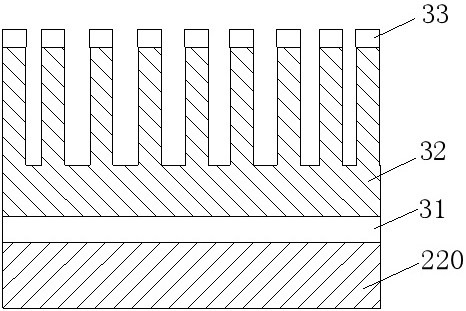

[0028] A preparation method of the above-mentioned anti-adhesive mucous layer, specifically comprising the following steps:

[0029] A1: make the base layer 31;

[0030] A2: Prepare a conductive layer 32 of nanoscale columnar matrix on the surface of the primer layer 31;

[0031] A3: An anti-adhesive layer 33 is provided on the top surface of the nanopillars of the conductive layer 32 to obtain an anti-adhesive mucous film layer.

[0032] Specifically, the conductive layer 32 is a mixed layer of SiO2 and nano-Ag in a nanoscale columnar matrix, and the mixed layer of SiO2 and nano-Ag is prepared by a sol-gel method.

[0033] Further, the preparation method of described SiO2 and nano-Ag mixed layer comprises the following steps:

[0034] a1: Slowly add tetraethyl orthosilicate (TEOS) dropwise to water, hydrochloric acid, NH4OH and absolute ethanol to form the precursor tetraethyl silicate;

[0035] a2: adding nano-silver paste to the precursor tetraethyl silicate to obtain a ...

Embodiment 1

[0046] Primer layer 31: an Ag material layer with a thickness of 3 μm.

[0047] Conductive layer 32: a mixed layer of SiO2 and nano-Ag, with a thickness of 20 μm; wherein, the components of the mixed layer of SiO2 and nano-Ag are as follows: tetraethyl orthosilicate (TEOS) 12%; water 1%; HCL 1%; NH4OH 1% ; Nano-silver paste 1%; the rest is absolute ethanol.

[0048] Anti-adhesive layer 33: Ag material layer with a thickness of 0.5 μm.

[0049] The preparation of the SiO2 and nano-Ag mixed layer: 12% tetraethyl orthosilicate (TEOS) was slowly added dropwise to 1% water, 1% hydrochloric acid, 1% NH4OH and absolute ethanol to form the precursor tetraethyl silicate Ethyl ester; add 1% nano-silver paste to the precursor tetraethyl silicate to obtain a mixed solution; fully stir the mixed solution and disperse it by ultrasonic to obtain a mixed wet gel of SiO2 and nano-Ag. Wherein, the particle size of the nano silver paste is 20nm; in the step S2, the volume ratio of the nano Ag ...

Embodiment 2

[0052] Primer layer 31: an Ag material layer with a thickness of 8 μm.

[0053] Conductive layer 32: a mixed layer of SiO2 and nano-Ag, with a thickness of 5 μm; wherein, the components of the mixed layer of SiO2 and nano-Ag are as follows: tetraethyl orthosilicate (TEOS) 16%; water 0.5%; HCL 0.5%; NH4OH 0.5% ; Nano silver paste 5%; the rest is absolute ethanol.

[0054] Anti-sticking layer 33: Au material layer with a thickness of 1 μm.

[0055] The preparation of the SiO2 and nano-Ag mixed layer: 16% tetraethyl orthosilicate (TEOS) was slowly added dropwise to 0.5% water, 0.5% hydrochloric acid, 0.5% NH4OH and absolute ethanol to form the precursor tetraethyl silicate Ethyl ester; add 5% nano-silver paste to the precursor tetraethyl silicate to obtain a mixed solution; fully stir the mixed solution and disperse it by ultrasonic to obtain a mixed wet gel of SiO2 and nano-Ag. Wherein, the particle size of the nano-silver paste is 30nm; in the step S2, the volume ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com