Graphene compound material and production process thereof

A graphene composite and composite material technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of low reusable times, poor mechanical properties, perforation and cuts, etc. Achieve the effect of light weight, low cost, and avoid packaging waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

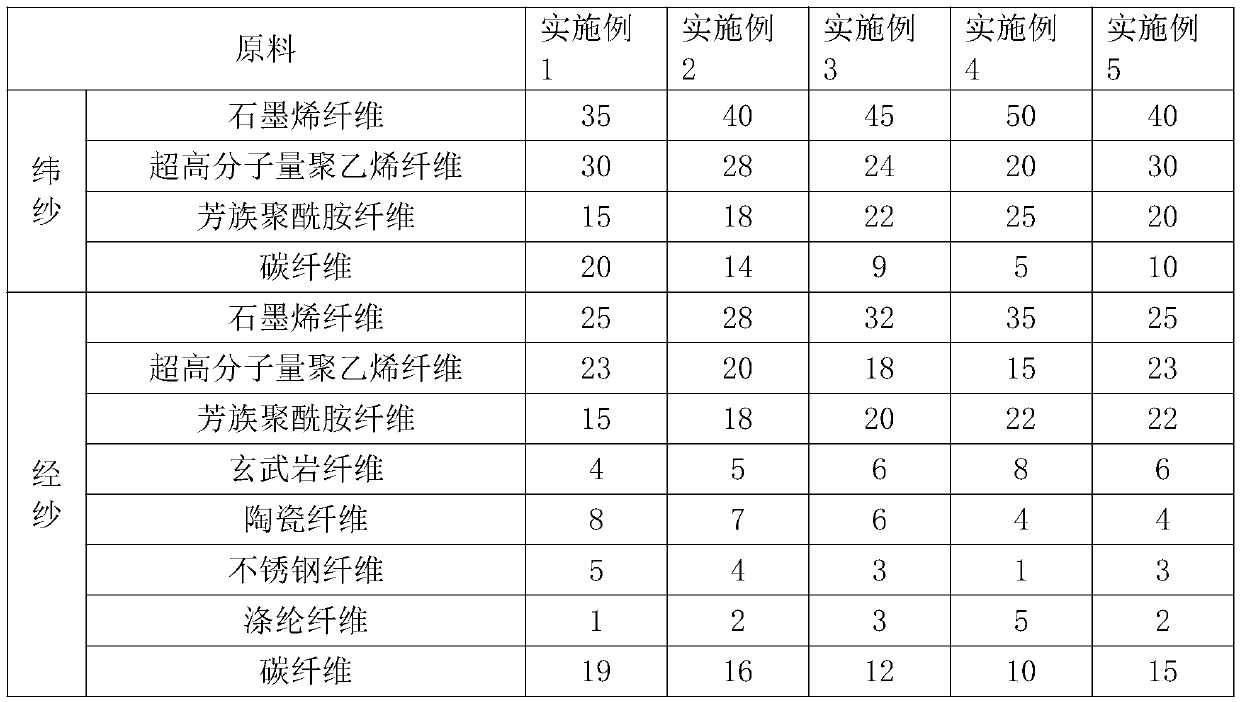

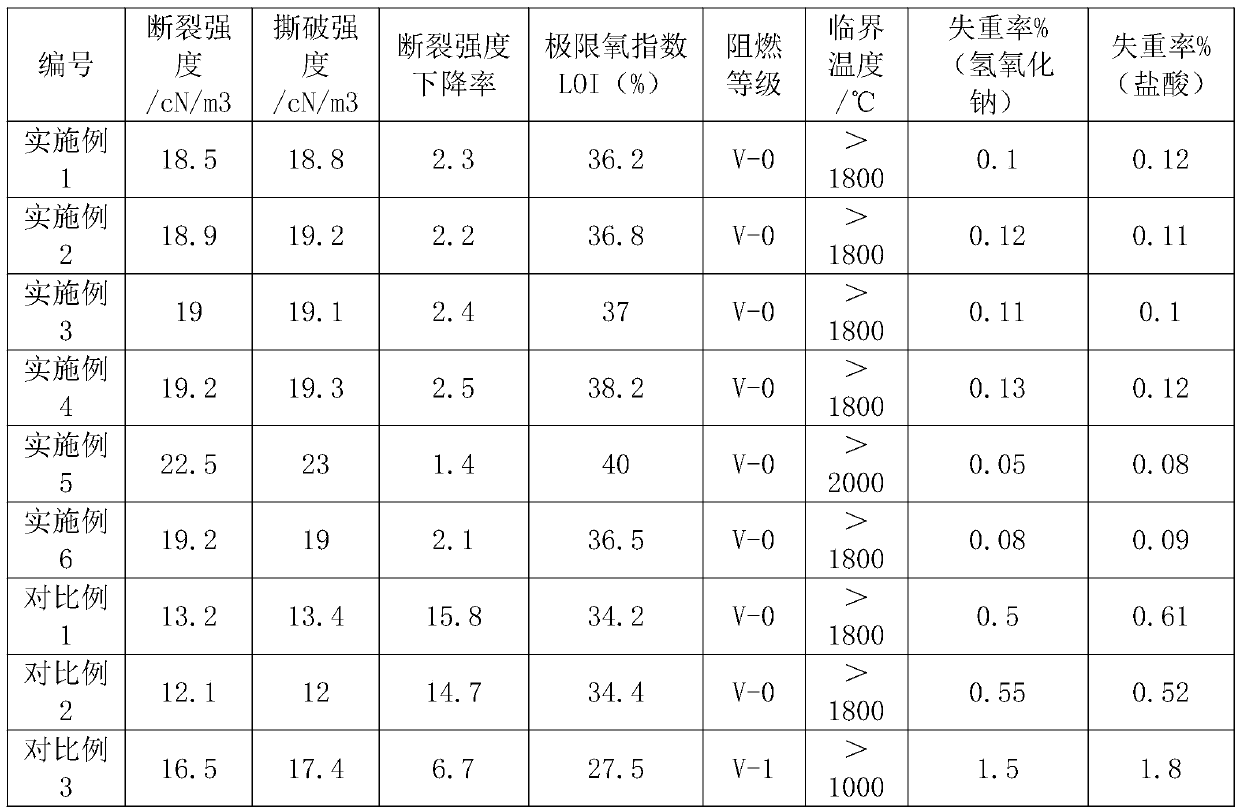

[0071] Embodiment 1: as figure 1 Shown, a kind of graphene composite material comprises silica airgel layer 1 and is bonded in the graphene composite fiber cloth 2 of silica airgel layer 1 both sides, graphene composite fiber cloth 2 is made of warp yarn and weft yarn Woven. The weft yarn is made of graphene fiber, ultra-high molecular weight polyethylene fiber, aramid fiber, and carbon fiber; the warp yarn is made of graphene fiber, ultra-high molecular weight polyethylene fiber, aramid fiber, carbon fiber, basalt fiber, ceramic fiber , stainless steel fiber, polyester fiber blended. The raw materials and weight percentages of warp and weft yarns are shown in Table 1.

[0072] A kind of production technology of graphene composite material, comprises the following steps:

[0073] Step 1, blending graphene fibers, ultra-high molecular weight polyethylene fibers, aramid fibers, and carbon fibers into weft yarns;

[0074] Step 2, blending graphene fibers, ultra-high molecular...

Embodiment 2-5

[0077] Embodiment 2-5: a graphene composite material, the difference from embodiment 1 is that the raw materials and weight percentages of the warp and weft yarns are as shown in Table 1.

[0078] The raw material of warp yarn and weft yarn and weight percent thereof in the embodiment 1-5 of table 1

[0079]

Embodiment 6

[0080] Embodiment 6: a kind of graphene composite material, the difference with embodiment 1 is, as figure 1 As shown, the side of the graphene composite fiber cloth 2 away from the silica airgel layer 1 is coated with a silica gel layer 3; Step 4 specifically includes: taking two pieces of graphene composite fiber cloth 2, coating the silica airgel Lay it on the opposite side of the graphene composite fiber cloth 2, and stick it together, then coat the side of the graphene composite fiber cloth 2 away from the silica airgel layer 1 with silica gel, and obtain a graphene composite material after curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com