Rice inter-row weeding component suitable for lateral seedling avoiding control

A horizontal and seedling-avoiding technology, applied in the field of agricultural machinery, can solve the problems of large lateral soil contact area of weeding parts, affecting normal growth, serious seedling avoidance and soil scraping, etc., to achieve stability, reduce lateral soil contact area, The effect of reducing the amount of ground breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

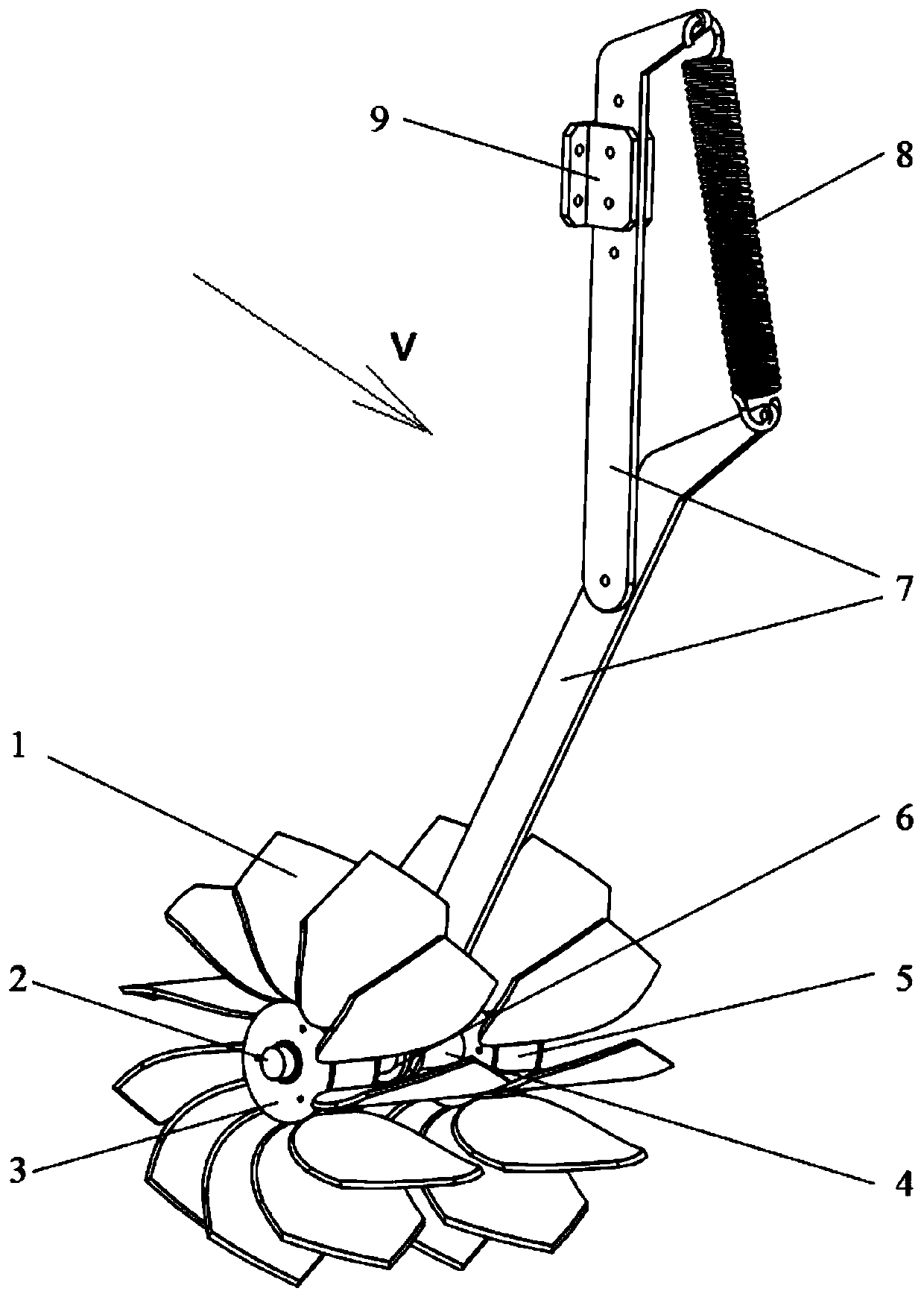

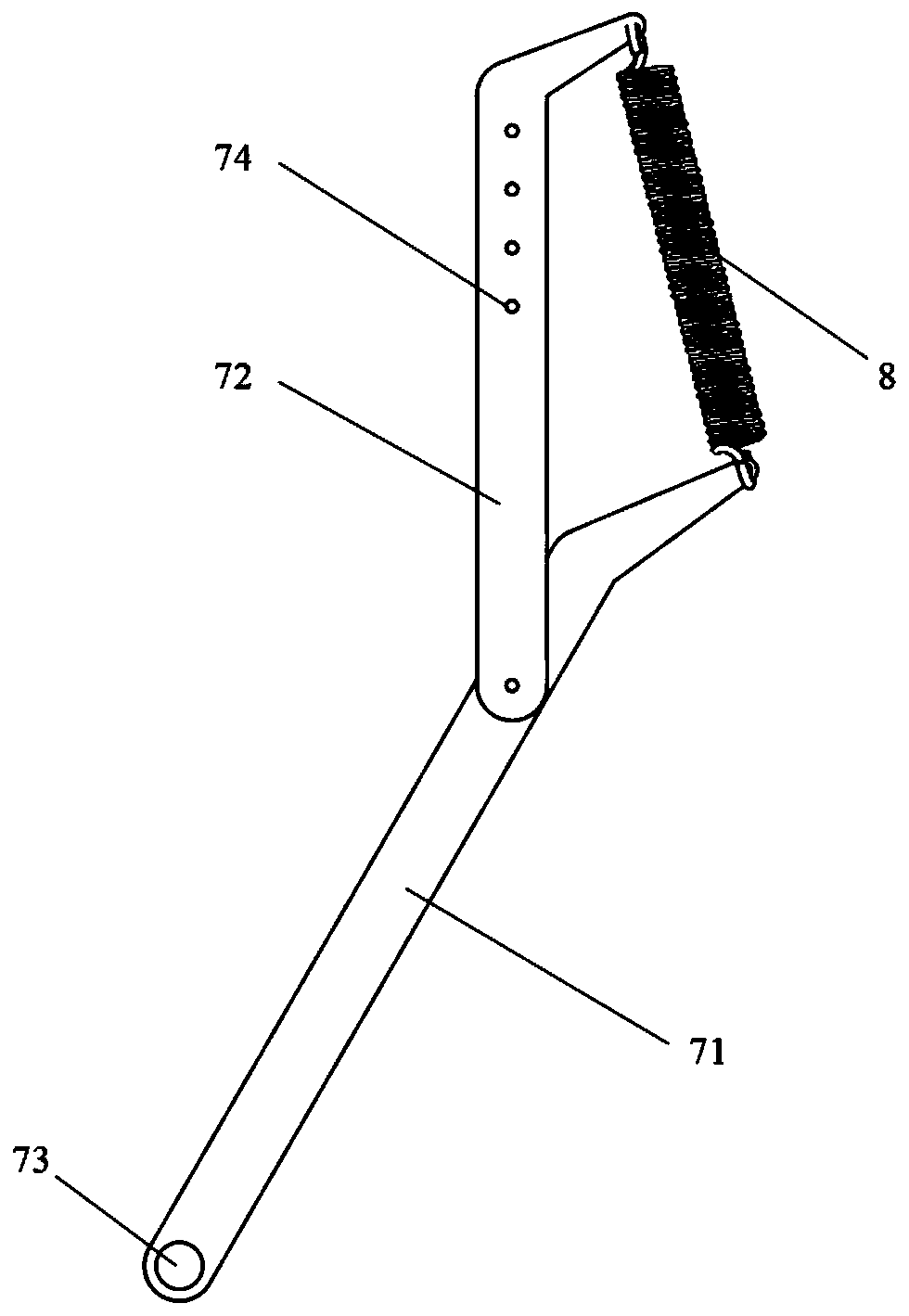

[0029] A paddy inter-row weeding component suitable for horizontal control of seedling avoidance, comprising a weeding knife, a stepped shaft, and a walking frame; the stepped shaft is mounted on a weeding machine through the trailing frame, and the weeding knife is mounted on the stepped shaft.

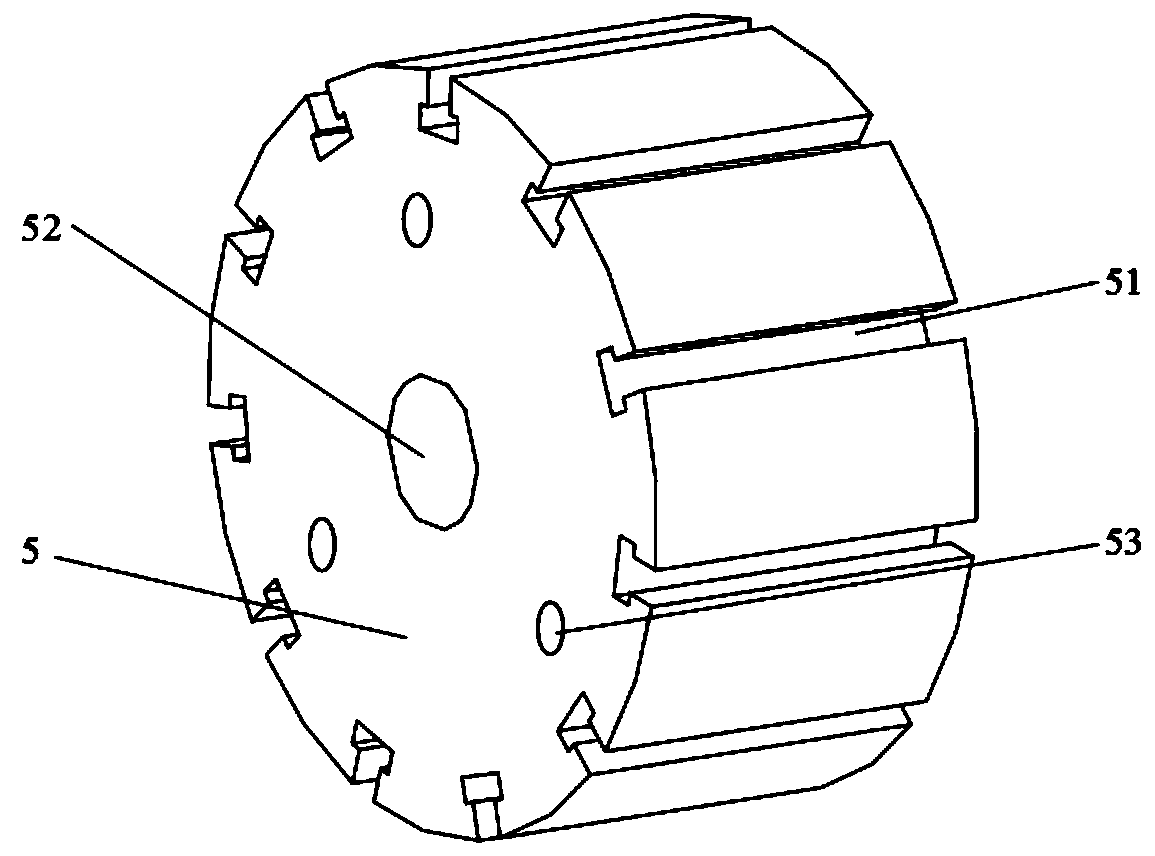

[0030] The weeding knife includes a blade hub installed on a stepped shaft, a plurality of weeding blades and baffles that are evenly distributed in the circumferential direction on the outside of the blade hub, the root of the weeding blade is connected to the blade hub, and the weeding blade is formed from the inner root to the outer blade. arc. In this embodiment, there are two weeding knives, which are symmetrically arranged left and right, and the imitation frame is located in the middle of the two weeding knives.

[0031] The weeding blade includes a front cutting surface, a back cutting surface and a cutting edge; Figure 5 As shown in the side view direction, both the front ...

Embodiment 2

[0039] The inclination angle, back section, and front section of the cutting edge of the weeding blade are selected from the Archimedes spiral under different proportional constants, which are determined by the soil type and the material properties of the weeding blade. The width of the weeding blade is determined by the working parameters of different machine transplanting. , The length design of the weeding blade (that is, the maximum working depth) is determined by the specific weeding operation requirements. The inclination angle of the cutting edge selected by the weeding blade in this embodiment is 30°, the proportional constant of the Archimedes spiral is 31, the width of the weeding blade is 100 mm, and the length is 80 mm.

[0040] The parts not mentioned in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com