Photoelectric sensor based on copper-doped cadmium sulfide nanowires and preparation method of photoelectric sensor

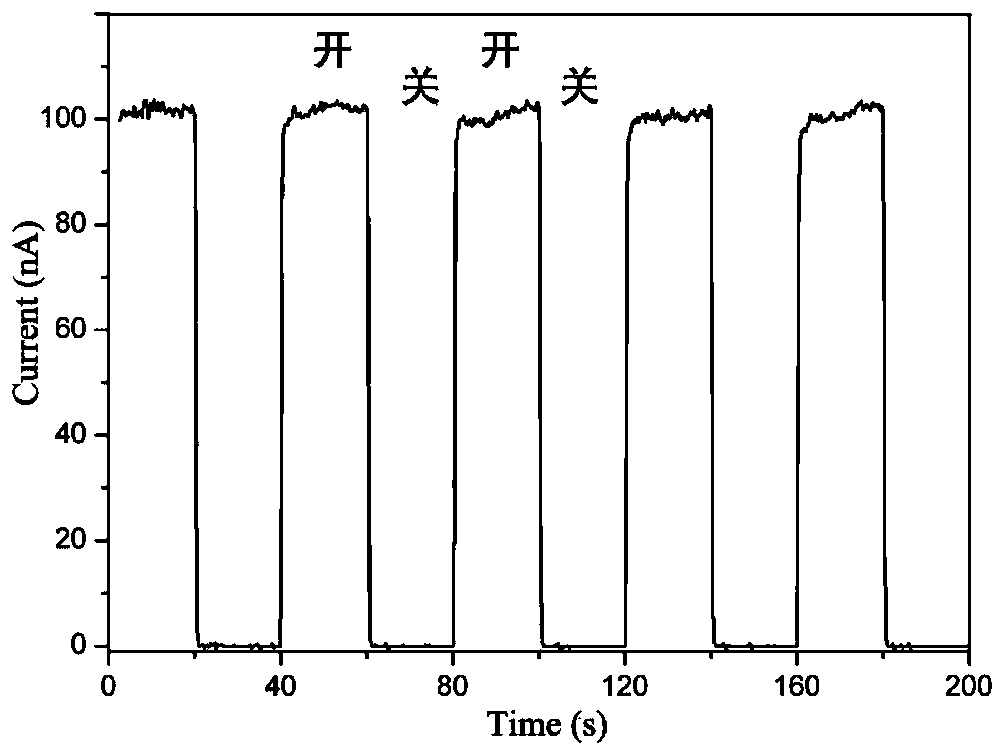

A photoelectric sensor, nanowire technology, applied in cadmium sulfide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of raw material waste, poor temperature controllability, low deposition efficiency, etc., and achieve no surface pollution. , The effect of less crystal defects and small device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

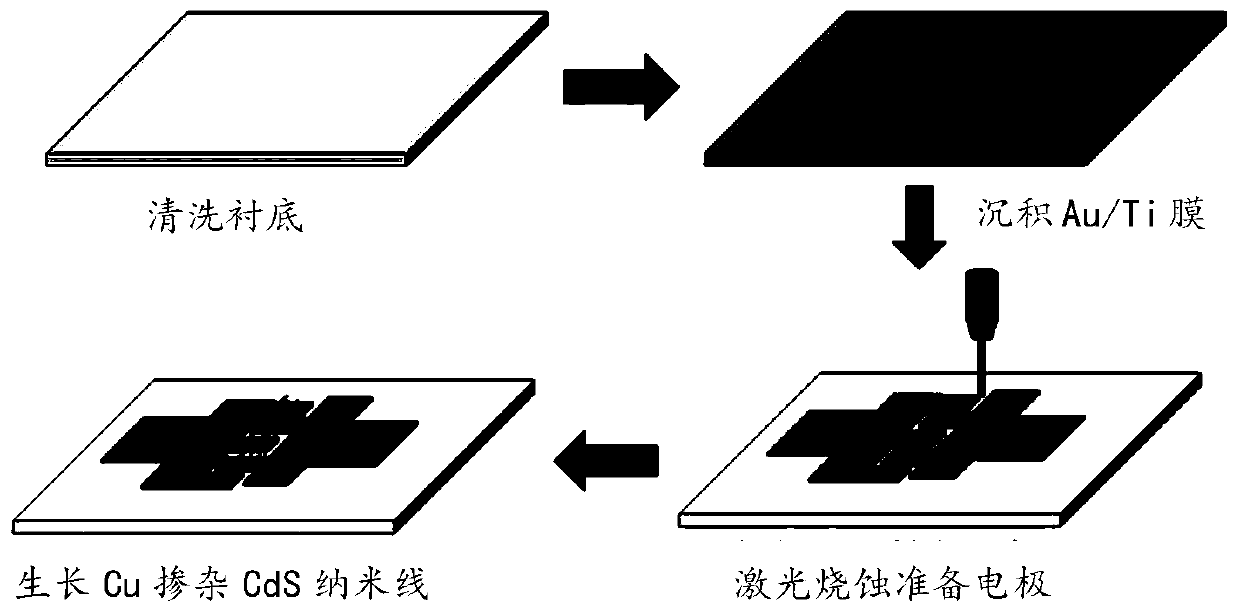

[0021] The method process used in the present invention is as figure 1 As shown, including cleaning the substrate, depositing Au / Ti film, preparing electrodes by laser ablation and growing Cu-doped CdS nanowires, the specific steps are as follows:

[0022] (1) With the alumina ceramic sheet as the substrate, it was cleaned with ethanol, acetone, and deionized water successively, and then dried with nitrogen gas. The hollow mask was used to cover, and several "cross" shapes were deposited on the surface of the substrate by electron beam evaporation. Au / Ti film array, the thickness of the metal layer is Au: 20nm, Ti: 100nm.

[0023] (2) Take out the substrate, use a UV laser marking machine to ablate and carve an insulating groove in the middle of the Au / Ti film along the set square wave route, with a width of about 4 μm, and prepare two rows of interdigitated electrodes on the metal film . A single electrode has a width of about 10 μm and a length of 30 μm.

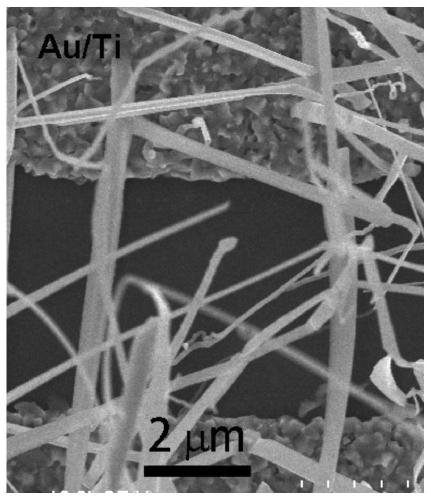

[0024] (3) Cu-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com