Double helical large diameter pouring pile concrete cooling pipe

A helical tube and helical technology, applied in the field of concrete cooling pipes for double helical large-diameter cast-in-place piles, can solve the lack of large-diameter cast-in-place pile concrete maintenance devices and technologies, the absence of large-diameter cast-in-place pile temperature control devices and maintenance technologies, Plum-shaped encrypted cooling water pipe device can not be used to achieve the effect of avoiding early freezing damage, accelerating heat conduction, and preventing temperature cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below with reference to the drawings and a specific embodiment.

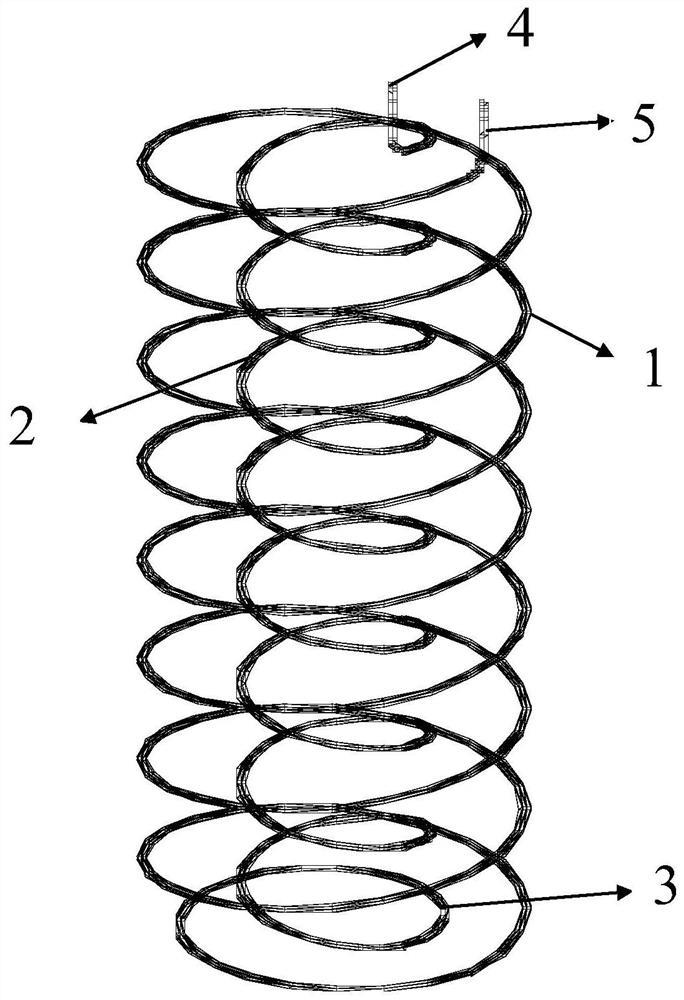

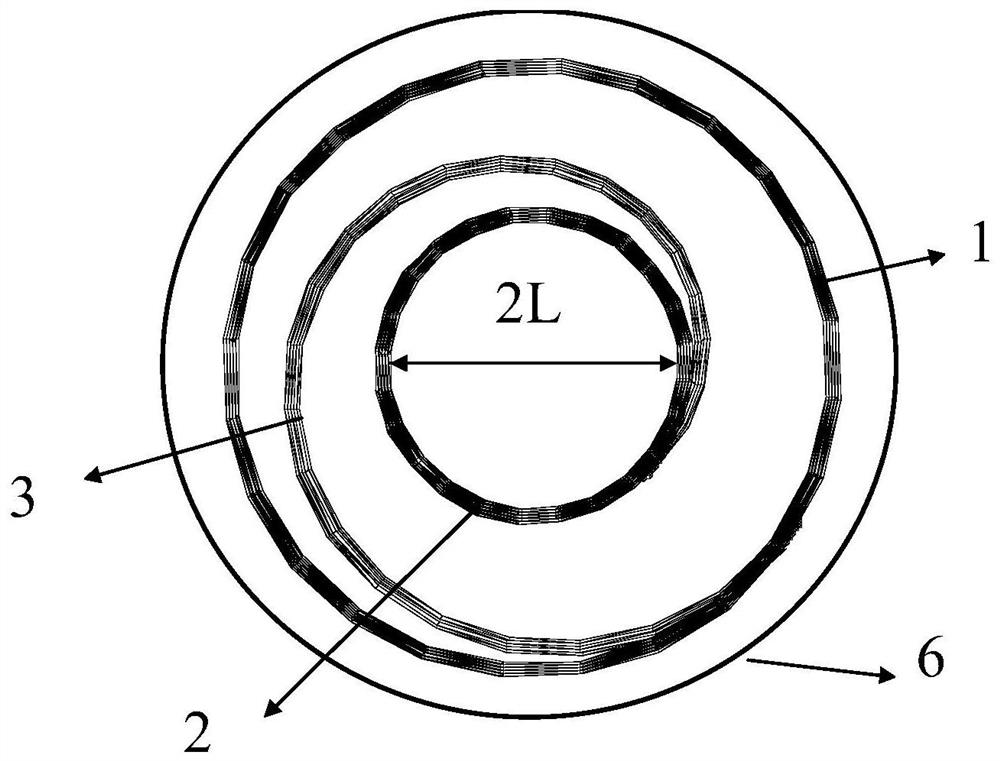

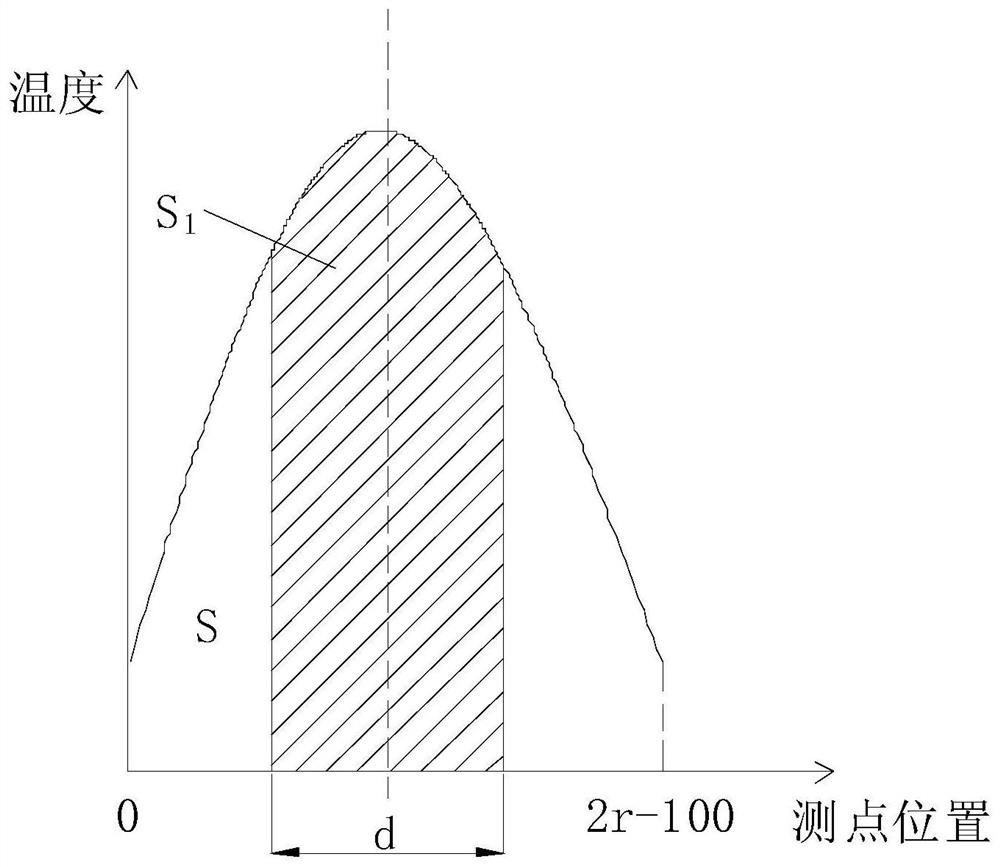

[0028]Such asfigure 1 As shown, this embodiment is composed of a steel outer spiral tube 1, an inner spiral tube 2, and a bottom connecting tube 3 with the same pipe diameter. The outer spiral tube 1 is fixed on the steel cage framework of the pile body in the form of a cylindrical spiral line. , The diameter D of the cylindrical spiral line is equal to the diameter of the steel cage. According to the design of the pile body steel cage length of 15m, the lead H is taken as 1.5m. From the top of the pile, the rotation direction of the outer spiral tube 1 is clockwise; The inner spiral tube 2 is vertically fixed on the internal support beam of the steel cage, in the form of a cylindrical spiral. The diameter of the cylindrical spiral is d and the lead h is 1m. Seen from the top of the pile, the spiral of the inner spiral tube 2 The direction is counterclockwise; the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com