Construction method of widening high-fill subgrade with foam light soil

A technology of foam lightweight soil and construction method, which is applied in basic structure engineering, roads, excavation and other directions, can solve the problems of embankment grading covering a wide area, large impact of post-construction settlement, large vertical additional stress, etc. cost, the effect of reducing water seepage, reducing material loss and engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

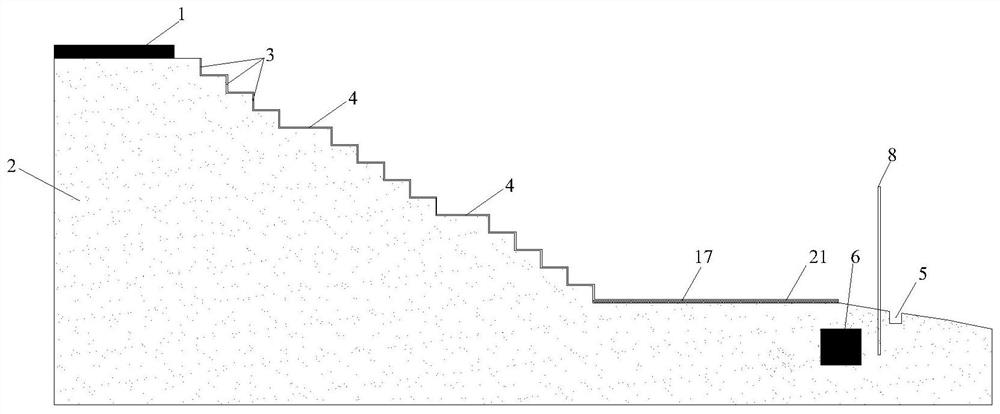

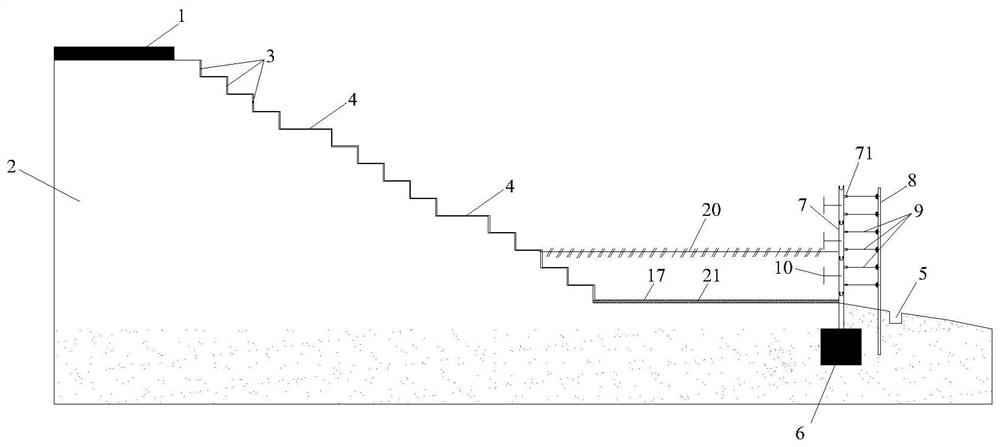

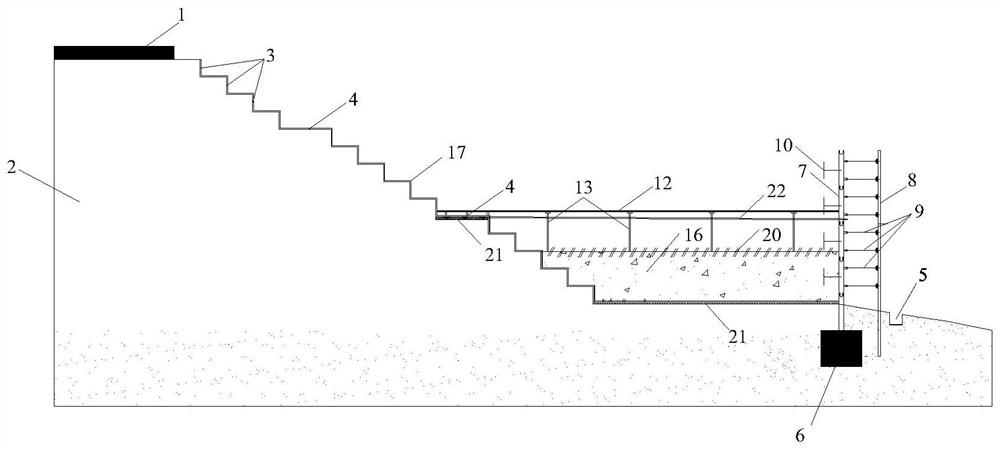

[0049] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 12 , the embodiments of the present invention are described in detail, the following embodiments are implemented under the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0050] The height of the filling area is 8m, and the width of the subgrade widening is two lanes and two sidewalks, totaling 12.5m, and the widening length is 2.5km. The cement is made of ordinary silicon PO42.5 (R). The anchor cables and drainage pipes are installed horizontally on the large platform. The horizontal spacing of the anchor cables is 3m, and the horizontal spacing of the drainage pipes is 5m. The steel mesh of the platform is galvanized with Φ3~4mm@5cm×5cm Barbed wire, the diameter of the reinforced plate is 0.3m, and the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com