Method for recovering selenium from high tellurium, silver and selenium slag through short process

A short-process, selenium recovery technology, which is applied in chemical instruments and methods, selenium/tellurium compounds, and process efficiency improvement, etc., can solve the problems of limited selenium content, difficulty in separation, and difficulty in high-value recycling of selenium and tellurium. The effect of optimizing process parameters, high product purity and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

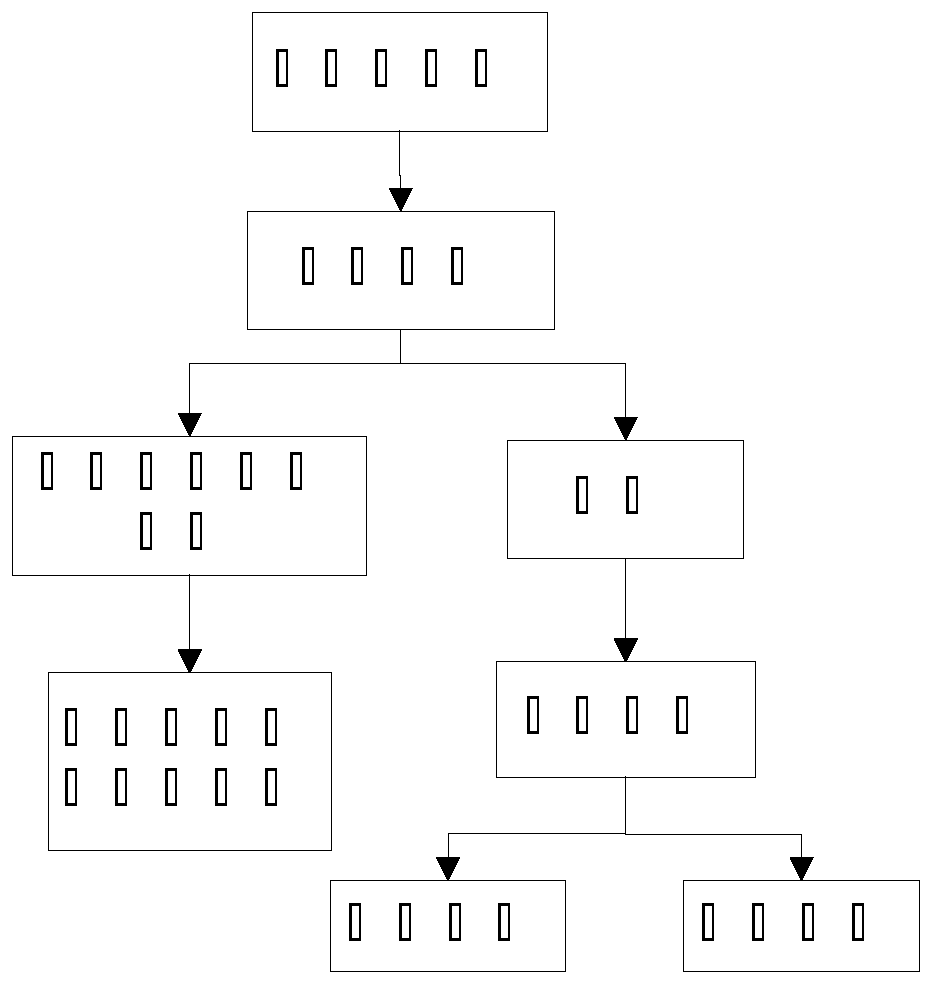

Method used

Image

Examples

Embodiment 1

[0020] The present embodiment provides a method for recovering selenium from high-tellurium silver selenium slag in a short process, and the specific process is as follows:

[0021] 10kg of high-tellurium silver selenium slag containing 85% selenium and 3.2% tellurium was taken as the recovered raw material, and the high-tellurium silver selenium slag was placed in a vacuum distillation furnace and vacuum distilled at 20Pa and 300°C for 2 hours.

[0022] The collected 8.5kg crude selenium was placed in a selenium oxidation furnace for oxidation, and the oxygen flow was controlled for 10m 3 / h, temperature 570 ℃, reaction 3h. 11.829kg of selenium dioxide was collected.

[0023] The residual silver, copper, tellurium-containing bottom slag and tellurium-containing bottom slag are taken out and sent back to the copper anode slime treatment process to recover valuable elements silver, copper and tellurium.

Embodiment 2

[0025] 10kg of high tellurium silver selenium slag containing 80% selenium and 3.6% tellurium was taken as the recycled raw material. The high tellurium silver selenium slag was placed in a vacuum distillation furnace and distilled at 100Pa and 350°C for 3h.

[0026] The collected 8.016kg crude selenium was placed in a selenium oxidation furnace for oxidation, and the oxygen flow was controlled to 6m 3 / h, temperature 500 ℃, reaction 3h. 11.167kg of selenium dioxide was collected.

[0027] The residual silver, copper, tellurium-containing bottom slag and tellurium-containing bottom slag are taken out and sent back to the copper anode slime treatment process to recover valuable elements silver, copper and tellurium.

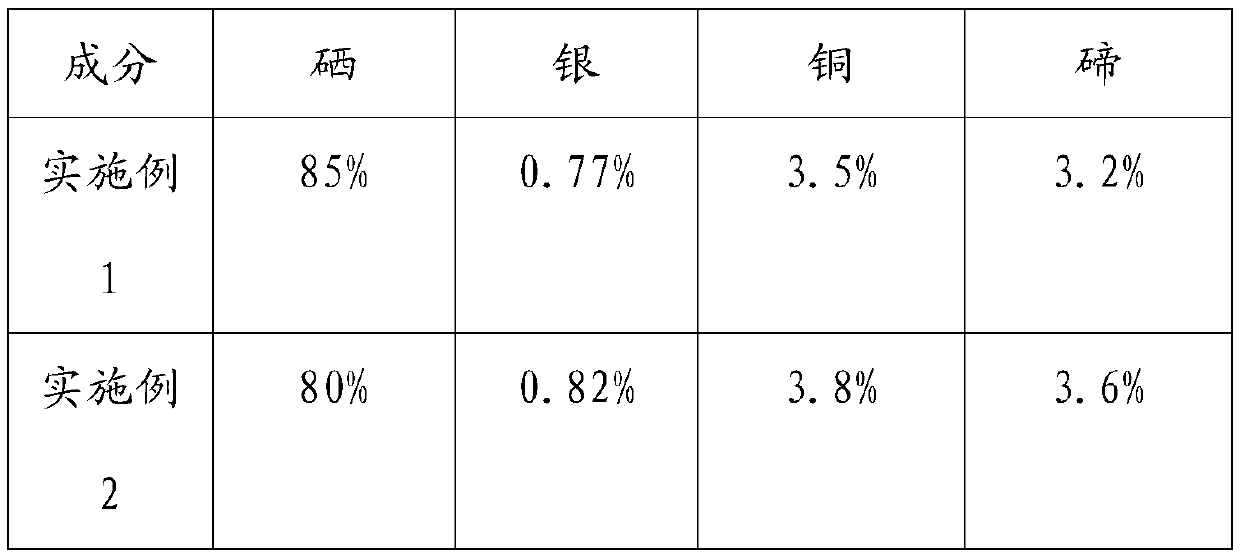

[0028] The composition of the high tellurium silver selenium slag in Example 1 and Example 2 is shown in Table 1 below:

[0029] Table 1

[0030]

[0031] The implementation effect of embodiment 1 and embodiment 2 is shown in table 2:

[0032] Table 2

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com