Rotary jet flow sprayer structure for washing gun

A technology of irrigation gun and jet nozzle, which is applied in the field of rotary jet nozzle structure for irrigation gun, which can solve the problems of irrigation liquid splashing, increased risk of surgical site infection, high pressure of soft tissue, etc., and achieves reduced impact area and ideal wound surface irrigation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

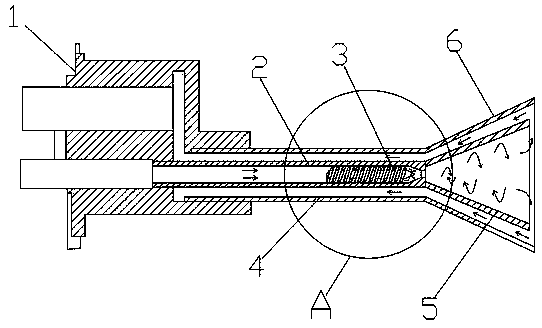

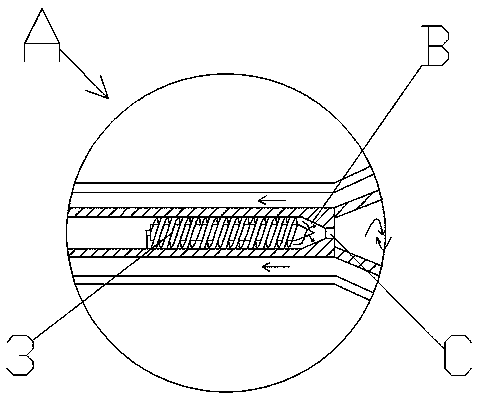

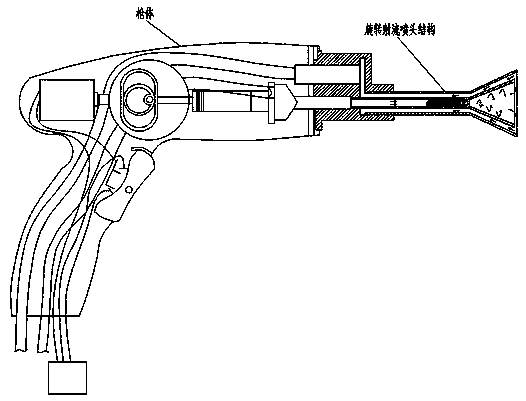

[0019] see Figure 1 to Figure 4 As shown, a rotating water jet nozzle structure for a flushing gun includes a head-body joint port 1, a chemical liquid nozzle 2, a spiral generator 3, a chemical liquid recovery pipe 4, a first protective cover 5 and a second protective cover 6, The medicine liquid nozzle 2 is set inside the medicine liquid recovery pipe 4, and the medicine liquid nozzle 2 and the medicine liquid recovery pipe 4 are respectively connected inside the cavity of the flushing gun, and the head end of the medicine liquid recovery pipe 4 is connected to the head-body joint port 1 , the spiral generator 3 is fixedly connected to the outlet of the liquid medicine nozzle 2 through a bracket, the exit of the medicine liquid nozzle 2 is provided with a tapered cavity structure B and a transition zone C, the first protective cover 5 and the liquid medicine nozzle 2 connected, the second protective cover 6 is connected with the liquid medicine recovery pipe 4;

[0020] Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com