Circuit board punching mold and punching method thereof

A board stamping and mold technology, which is applied in the field of circuit board stamping dies and stamping molds, can solve the problems of insufficient impact tonnage, high hardness, and large damage to the shape of rigid circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

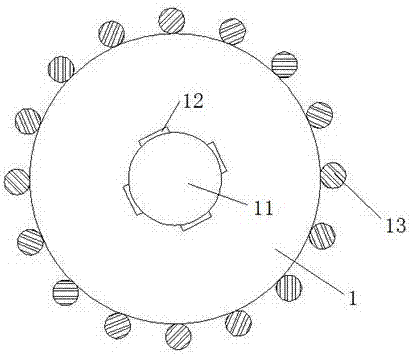

[0023] A circuit board stamping die, comprising a body 1, characterized in that the center of the body 1 is provided with a protrusion 11, and the protrusion 11 is symmetrically provided with reinforcing ribs 12; the edge of the body 1 is symmetrically provided with an estimation portion 13 , the estimation part 13 is higher than the body 11-10mm, and the body 1 is integrally connected with the estimation part 13 .

[0024] Further, the body 1 is in the shape of a round cake.

[0025] Further, the estimation part 13 is a cylinder. The diameter of the estimation part 13 is 0.5-2 mm. The horizontal distance between the adjacent estimation parts 13 is 10-20 mm.

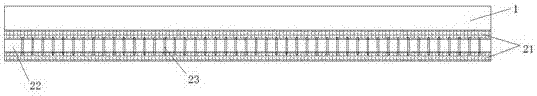

[0026] Further, a buffer portion is provided under the body 1 , the buffer portion includes a first buffer layer 21 and a second buffer layer 22 , and the first buffer layer 21 is symmetrically arranged at both ends of the second buffer layer 22 .

[0027] Further, the first buffer layer 21 is a polymer hydrogel layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com