A combined desulfurization and denitrification device and process

A desulfurization, denitrification and denitration technology, which is applied in the field of desulfurization and denitrification to achieve the effects of high desulfurization and denitrification efficiency, improved contact effect and shortened treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

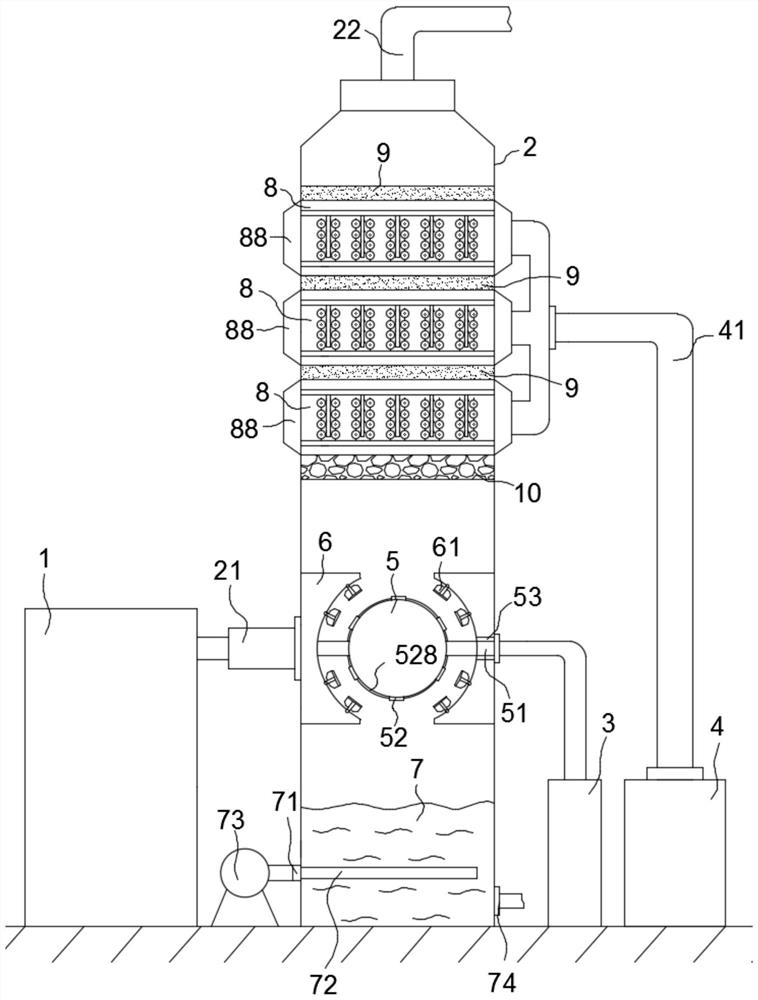

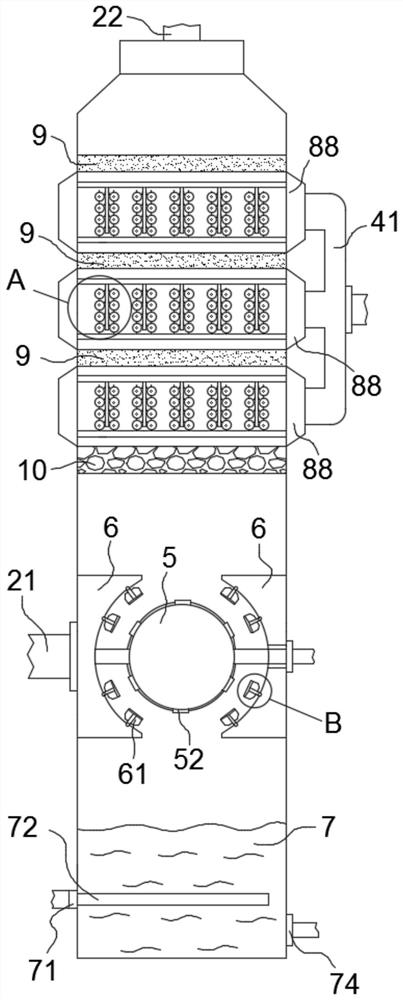

[0049] Such as figure 1 As shown, a combined desulfurization and denitrification device mainly includes a dust removal system 1, a desulfurization and denitrification tower 2, an ammonia water tank 3, and an ozone tank 4; There is an exhaust port 22, and the interior of the desulfurization and denitrification tower 2 is divided into upper and lower parts, and the inner lower part and inner upper part correspond to the desulfurization section and the denitrification section; the dust removal system 1 is connected to the smoke inlet 21;

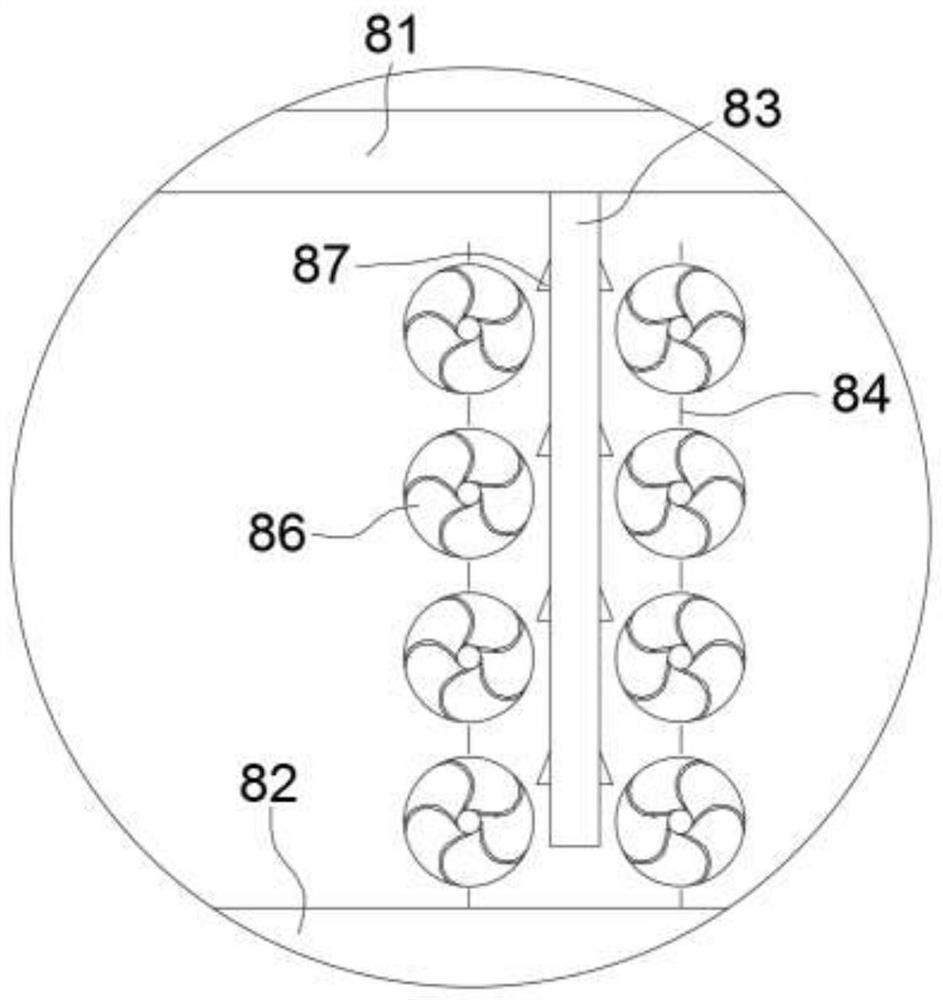

[0050] Such as figure 2 As shown, the desulfurization section includes a spray ball 5, a flue gas dispersion ring 6, and an oxidation pool 7; the flue gas dispersion ring 6 is located on the inner wall of the desulfurization and denitrification tower 2 in the middle of the desulfurization section, and the inner surface of the longitudinal section of the flue gas dispersion ring 6 is Arc-shaped, the inner surface of the smoke dispersion ring 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com