An airtight structure of miniaturized microwave components

An air-tight structure, microwave component technology, applied in electrical components, sealed enclosures, chassis/cabinet/drawer parts, etc., can solve the problems of thick microwave components, large volume, and unfavorable miniaturization design of microwave components. , to achieve the effect of thin thickness, small overall volume and good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

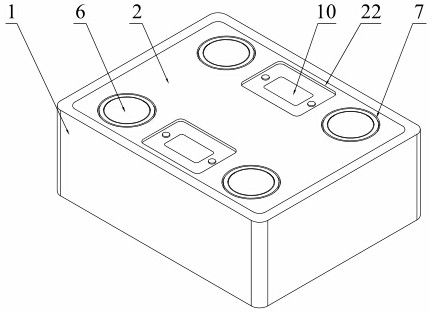

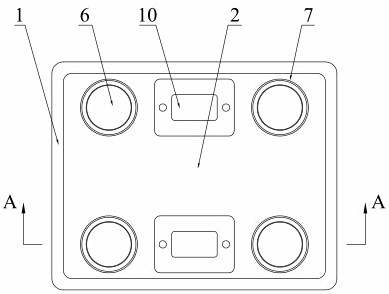

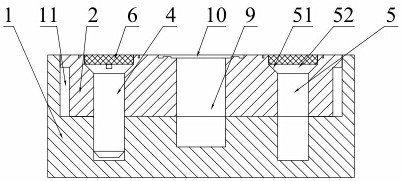

[0034] Such as Figure 1-8 As shown, a miniaturized microwave assembly airtight structure includes a housing 1 and a cover 2, the housing 1 and the cover 2 are locked and connected by screws 4 to form a chamber 11 for installing a chip 3, so The cover plate 2 is embedded in the chamber 11 to close the chamber 11, and the opening position of the screw hole 5 corresponding to the screw 4 is provided with a welding groove 52, and a screw hole airtight member 6 is embedded in the welding groove 52 , so that the screw hole 5 is closed, the cover plate 2 and the housing 1 are welded by laser sealing, and the screw hole airtight part 6 and the welding groove 52 are welded by laser sealing.

[0035]The airtight structure of a miniaturized microwave component in this embodiment is preferably provided with a cover plate 2 that can be integrally embedded in the cavity 11 of the housing 1, so that the weld seam formed between the cover plate 2 and the housing 1 on the same plane, And the...

Embodiment 2

[0041] Such as Figure 1-8 As shown, the airtight structure of a miniaturized microwave component of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom of the housing 1 is provided with a welding hole 12 for connecting the high and low frequency connector 8, and the cover After the board 2 is embedded in the chamber 11, at least one waveguide 9 is formed. The opening of the waveguide 9 is arranged on the cover plate 2, so that the opening direction of the waveguide 9 is in line with the microwave of the high-low frequency connector 8. The signal transmission direction is in the same normal direction, forming a vertical interconnection structure between the waveguide 9 and the high and low frequency connectors 8 .

[0042] The airtight structure of a miniaturized microwave component in this embodiment is used to weld the high and low frequency connector 8 by providing a welding hole 12 communicating with the chamber 11 on the housing 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com