Preparation method of flexible lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as unsatisfactory bending stability, electrochemical performance degradation, active material shedding, etc., and achieve good rate Effects of performance and cycle performance, reduction of interface resistance, and enhancement of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a lithium ion battery flexible negative electrode material, comprising the following steps:

[0042] (1) Add 0.5g of graphite flakes to 50mL of concentrated sulfuric acid, stir for 1h under ice-water bath conditions, then add 5g of potassium permanganate, continue stirring for 1h under ice-water bath conditions, and then under medium temperature 40°C and high temperature 90°C Stir respectively for 1.5 hours; add 1000mL deionized water several times at 90°C, and add 10mL hydrogen peroxide after the reaction is complete to obtain a clear bright yellow graphene oxide dispersion; wash the graphene oxide dispersion with acid, Freeze-drying to obtain powder;

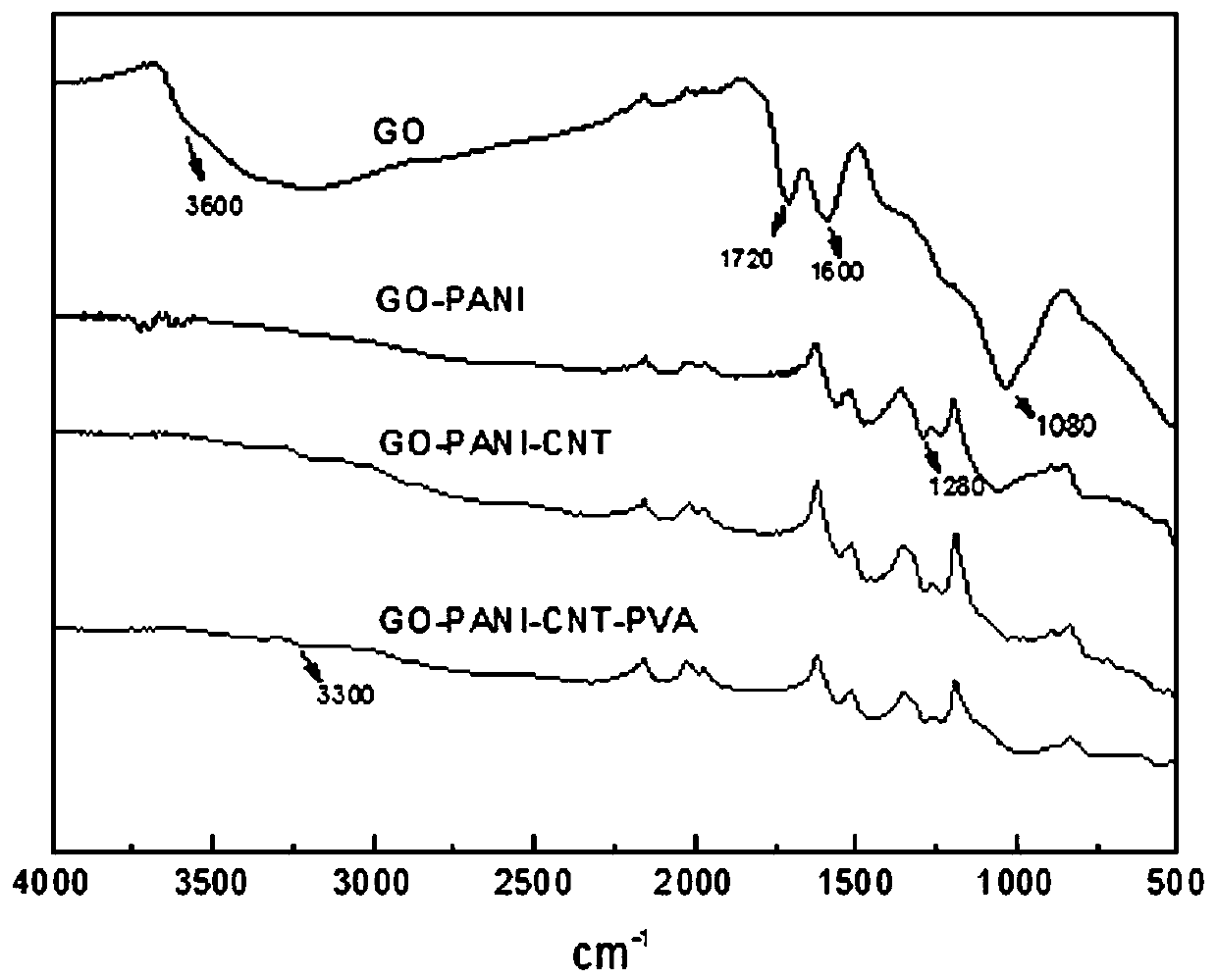

[0043] (2) Take 0.3 g of graphene oxide synthesized and dried in step (1), dissolve it in 60 ml of 1mol / L hydrochloric acid aqueous solution, ultrasonically disperse for 2 h, add 0.1 g of aniline monomer, stir magnetically for 1 h, then add 0.24 g Ammonium persulfate was reacted at 0°C for 24 hour...

Embodiment 2

[0053] A preparation method of a flexible lithium-ion battery negative electrode material, comprising the following steps:

[0054] (1) Add 0.5g of graphite flakes to 50mL of concentrated sulfuric acid, stir for 1h under ice-water bath conditions, then add 5g of potassium permanganate, continue stirring for 1h under ice-water bath conditions, and then under medium temperature 40°C and high temperature 90°C Stir respectively for 1.5 hours; add 1000mL deionized water several times at 90°C, and add 10mL hydrogen peroxide after the reaction is complete to obtain a clear bright yellow graphene oxide dispersion; wash the graphene oxide dispersion with acid, Freeze-drying to obtain powder;

[0055] (2) Take 0.3 g of graphene oxide synthesized and dried in step (1), dissolve it in 60 ml of N-methylpyrrolidone, disperse it ultrasonically for 2 h, add 0.1 g of aniline monomer, stir magnetically for 1 h, and then add 0.24 g of persulfuric acid Ammonium was reacted at 0°C for 24 hours, t...

Embodiment 3

[0062] A preparation method of a flexible lithium-ion battery negative electrode material, comprising the following steps:

[0063] (1) Add 0.5g of graphite flakes to 50mL of concentrated sulfuric acid, stir for 1h under ice-water bath conditions, then add 5g of potassium permanganate, continue stirring for 1h under ice-water bath conditions, and then under medium temperature 40°C and high temperature 90°C Stir respectively for 1.5 hours; add 1000mL deionized water several times at 90°C, and add 10mL hydrogen peroxide after the reaction is complete to obtain a clear bright yellow graphene oxide dispersion; wash the graphene oxide dispersion with acid, Freeze-drying to obtain powder;

[0064] (2) Take 0.3 g of graphene oxide synthesized and dried in step (1), dissolve it in 60 ml of deionized water, disperse it ultrasonically for 2 hours, and put monomer benzene and catalyst AlCl in a certain proportion under stirring. 3 and oxidant CuCl, slowly raised the temperature to 30°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com