Mixing and dissolving method for rubber asphalt containing liquid viscosity-reducing drag-reducing agent

A technology of rubber asphalt and drag reducing agent, which is used in building components, building insulation materials, buildings, etc., can solve the problems of hindered promotion of wet rubber asphalt, increase toxic gas emissions, poor construction and workability, etc., and achieve improved construction. The effect of environment, energy consumption reduction, road performance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

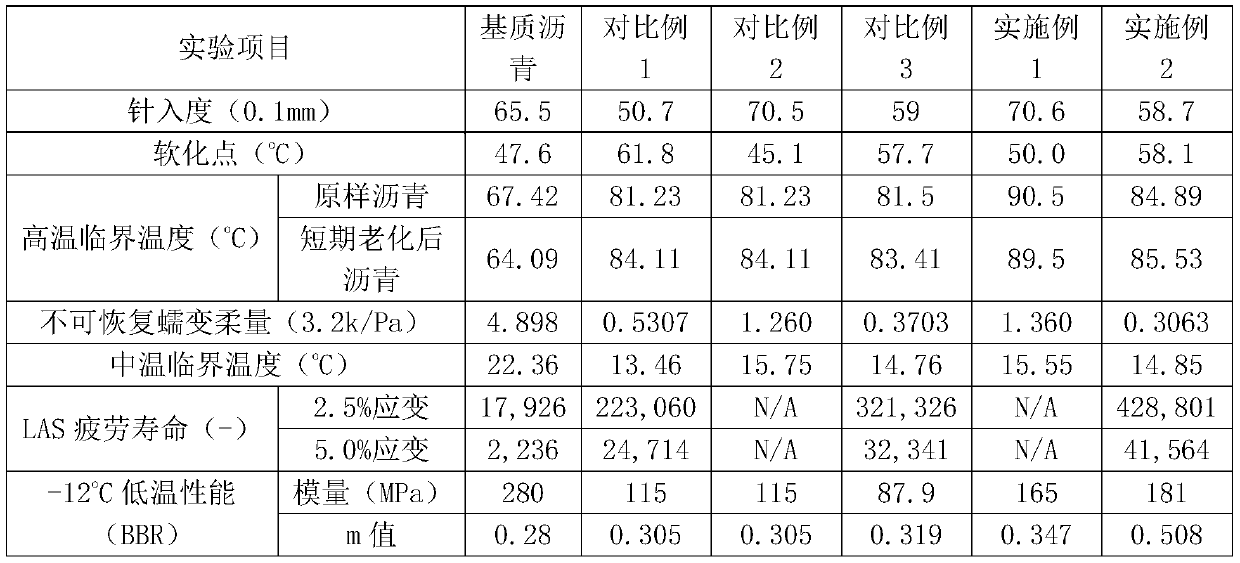

Examples

Embodiment 1

[0073] A rubber asphalt mixing method containing a liquid viscosity-reducing and drag-reducing agent is prepared by mixing the drag-reducing agent-rubber powder modifier with base asphalt.

[0074] The asphalt is base asphalt. The quality of base asphalt is 1000g, and the quality of drag reducer-rubber powder modifier is 23wt% of the total mass of rubber powder and base asphalt, which is 281g, wherein: the quality of rubber powder is 18wt% of the total mass of rubber powder and base asphalt , is 220g, and the rubber powder is desulfurized rubber, which is black and granular at normal temperature; Evotherm-DAT is selected as the viscosity and drag reducing agent, and the quality of Evotherm-DAT is 5wt% of the total mass of rubber powder and matrix asphalt, which is 61g. The liquid chemical warming agent is an amber viscous liquid at room temperature;

[0075] The process of improving the storage stability of wet rubber asphalt includes the following steps:

[0076] (1) Add 61...

Embodiment 2

[0083] A rubber asphalt mixing method containing a liquid viscosity-reducing and drag-reducing agent is prepared by mixing the drag-reducing agent-rubber powder modifier with matrix asphalt.

[0084] The asphalt is base asphalt. The quality of base asphalt is 1000g, and the quality of drag reducer-rubber powder modifier is 23wt% of the total mass of rubber powder and base asphalt, which is 281g, wherein: the quality of rubber powder is 18wt% of the total mass of rubber powder and base asphalt , which is 220g, the rubber powder is devulcanized rubber, which is black and granular at room temperature; the viscosity and drag reducing agent is medium-temperature coal coking heavy oil, and the quality of medium-temperature coal coking heavy oil is 5wt% of the total mass of rubber powder and base asphalt, which is 61g, the medium temperature coal coking heavy oil is dark brown viscous liquid at room temperature;

[0085] The process of improving the storage stability of wet rubber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com