Coal mine explosion-proof sealed wall and construction method thereof

A technology for closed walls and coal mines, which can be applied in mining equipment, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

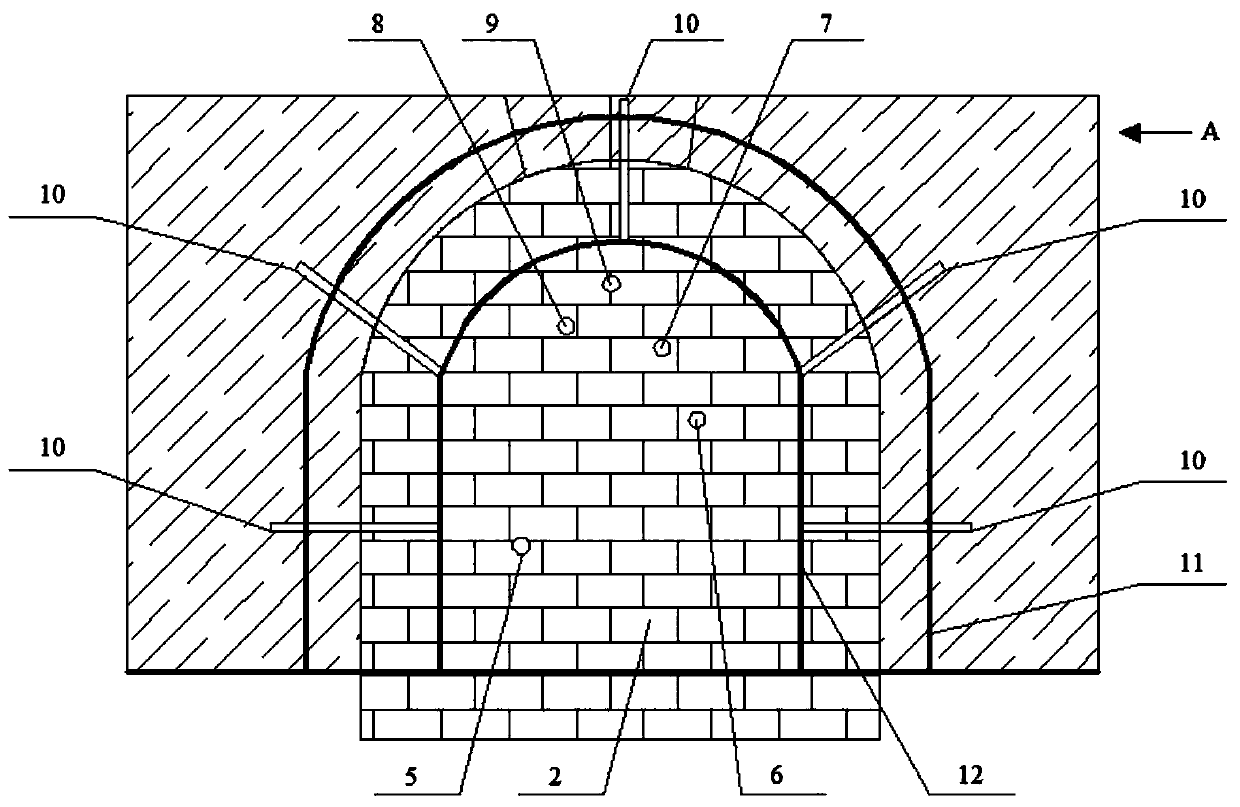

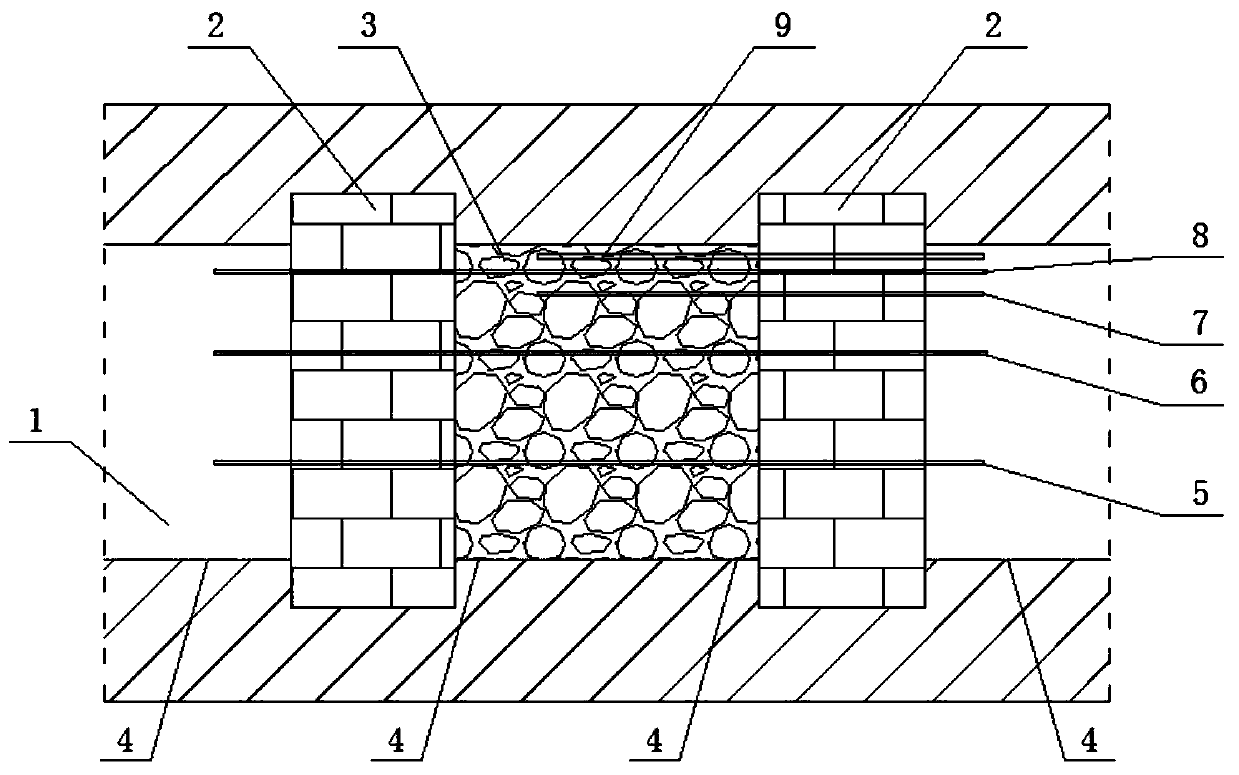

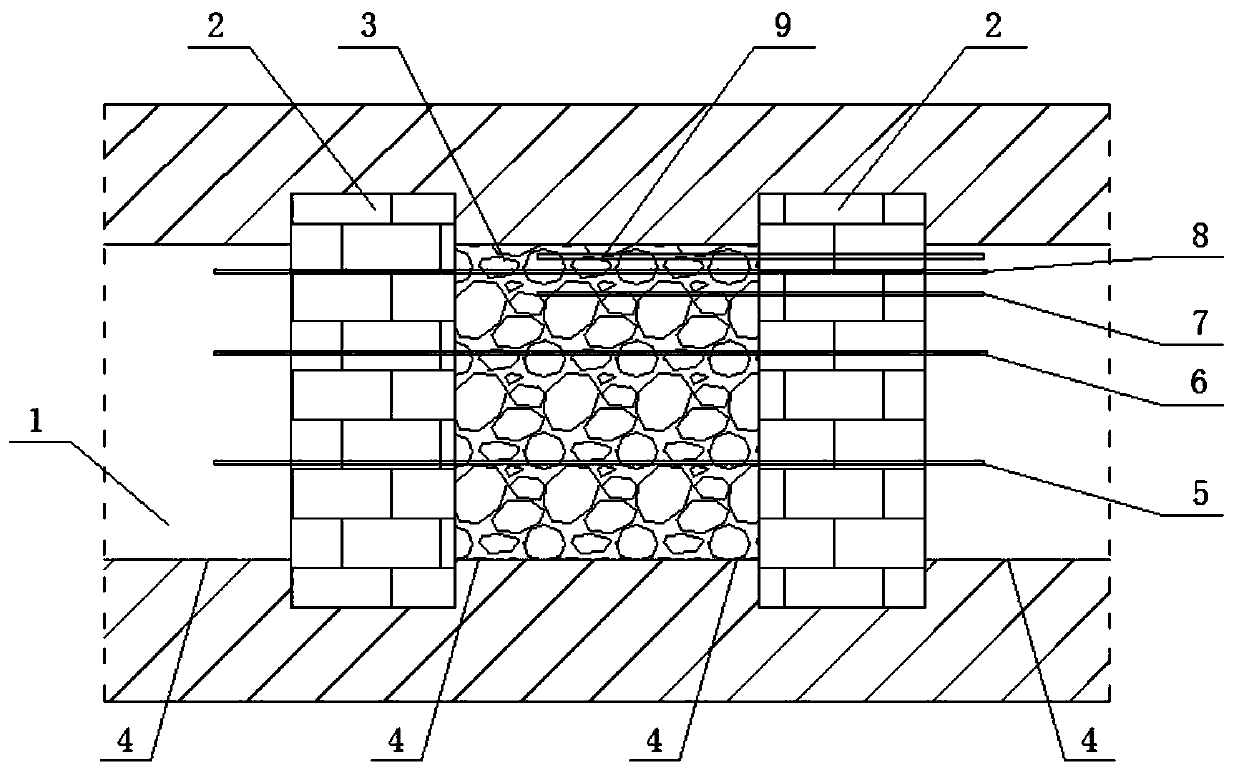

[0028] Such as figure 1 and 2 As shown, a coal mine explosion-proof airtight wall includes a roadway 1, two airtight walls 2, a filling wall 3 and four grouting areas 4, and two diggings are arranged in parallel upwards around the inner wall of the roadway 1 that needs to be sealed. The two cutouts are set at intervals, the two airtight walls 2 are respectively arranged in the two cutouts, and a filling wall 3 is arranged between the two airtight walls 2; the two airtight walls 2 Grouting areas 4 are respectively provided on the side walls of the roadway 1 on the side, and grouting areas 4 are respectively provided within 5m on both sides of the closed wall 2, and the grouting areas 4 are arranged in sequence from bottom to top between the two closed walls 2. Water pipe 5, observation pipe 6, filling pipe 7, gob grouting or nitrogen injection pipe 8 and inspection pipe 9, one end of filling pipe 7 goes through a closed wall 2 and goes deep into the roadway 1 between two close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com