Preparing method of stable-rheological-property fabric softener material

A technology of fabric softener and stable flow, applied in textiles and papermaking, improved handle fiber, fiber treatment, etc., can solve the problems of poor stability and rheological properties, and more solvents, so as to improve tear strength and reduce friction coefficient, the effect of good emulsification dispersion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

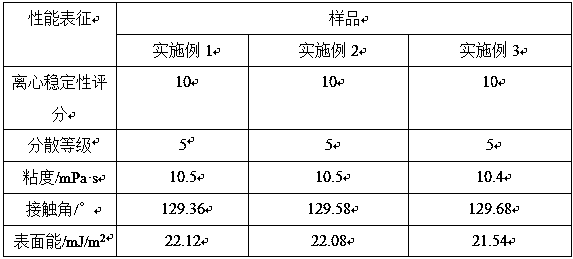

Embodiment 1

[0023] Take the severe saline-alkaline soil with a pH of 11, grind it, pass it through a 200-mesh sieve, collect the crushed particles and add the crushed particles to deionized water at a mass ratio of 1:10, stir and mix and let stand for 6 hours, and then place it at 3000rr Centrifuge at 1 / min, collect the supernatant, and obtain the leachate; according to the mass ratio of 1:10, add cornstarch to distilled water, stir and mix and place it at 80°C for 20 minutes, and use 1% sodium hydroxide respectively solution and 1% hydrochloric acid to adjust the pH to 6.0, stir and mix to obtain a mixed solution, then add trypsin to the mixed solution at a rate of 50 U / g, enzymatically treat it, and place it at 100°C for 10 minutes to inactivate the enzyme treatment. Cool to room temperature, dry in an oven for 6 hours, and grind to obtain modified particles; add casein to a 0.05mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a pH of 7.8 at a mass ratio...

Embodiment 2

[0025] Take the severe saline-alkaline soil with a pH of 11, grind it, pass it through a 200-mesh sieve, collect the crushed particles and add the crushed particles to deionized water at a mass ratio of 1:10, stir and mix and let it stand for 7 hours, then place it at 1000r Centrifuge at 1 / min, collect the supernatant, and obtain the leachate; according to the mass ratio of 1:10, add cornstarch to distilled water, stir and mix and place it at 82°C for 25 minutes, and use 1% sodium hydroxide respectively solution and 1% hydrochloric acid to adjust the pH to 6.0, stir and mix to obtain a mixed solution, then add trypsin to the mixed solution at a rate of 50 U / g, perform enzymatic hydrolysis treatment and place it at 100°C for 12 minutes to inactivate the enzyme treatment, and statically Cool to room temperature, dry in an oven for 7 hours, and grind to obtain modified particles; add casein to a 0.05 mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution wit...

Embodiment 3

[0027] Take the severe saline-alkaline soil with a pH of 11, grind it, pass it through a 200-mesh sieve, collect the crushed particles and add the crushed particles to deionized water at a mass ratio of 1:10, stir and mix and let stand for 8 hours, and then place it at 5000rr Centrifuge at 1 / min, collect the supernatant, and obtain the leachate; according to the mass ratio of 1:10, add cornstarch to distilled water, stir and mix and place it at 85°C for 30 minutes, and use 1% sodium hydroxide solution and 1% hydrochloric acid to adjust the pH to 6.0, stir and mix to obtain a mixed solution, then add trypsin to the mixed solution at a rate of 50 U / g, perform enzymatic hydrolysis treatment and place it at 100°C for 15 minutes to inactivate the enzyme treatment, and statically Cool to room temperature, dry in an oven for 8 hours, and grind to obtain modified particles; add casein to a 0.05 mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a pH of 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com