Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

A waterproof coating, high temperature resistant technology, applied in fireproof coatings, asphalt coatings, other rubber coatings, etc., can solve problems such as poor heat resistance, achieve good low temperature flexibility, good adhesion and lasting adhesion, and easy construction quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

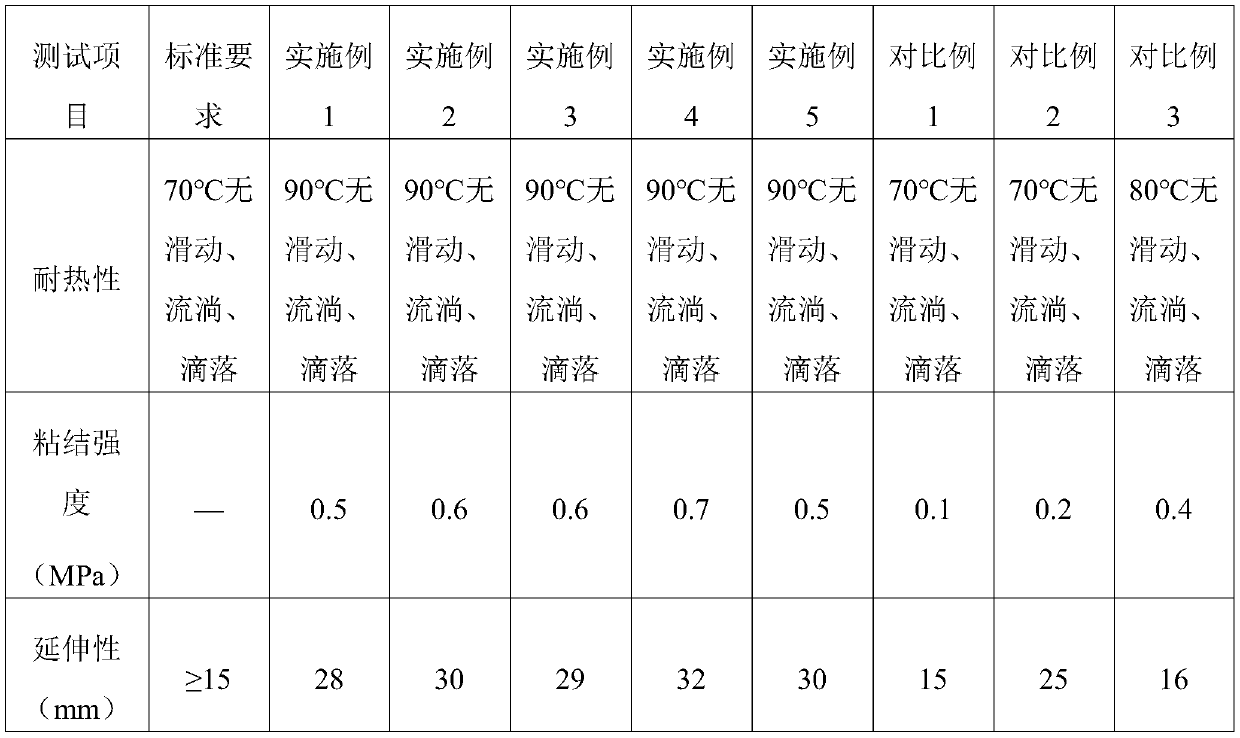

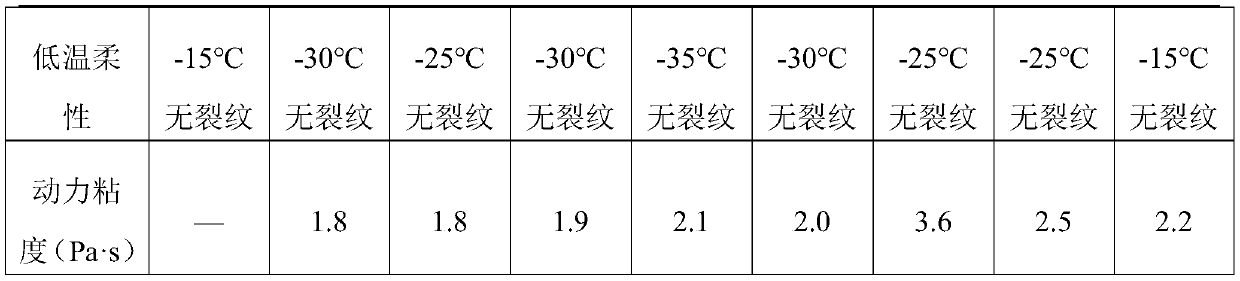

Examples

Embodiment 1

[0029] A novel high temperature resistant non-curing waterproof coating consists of the following components by weight percentage:

[0030] No. 90 petroleum asphalt 35%, naphthenic rubber oil 18%, waste tire rubber powder 10%, styrene-butadiene rubber 8%, SBS14012%, terpene resin 6%, fly ash 15%, polyamide wax 3%, low molecular weight Polyethylene wax 3%,

[0031] Its preparation method comprises the following steps:

[0032] S1. According to the above formula, weigh each component for later use;

[0033] S2. Pump No. 90 petroleum asphalt and naphthenic rubber oil in the molten state into the reaction kettle through the insulation pipeline, and stir until the temperature of the material reaches 150° C. to obtain a mixed oil;

[0034] S3. Putting SBS 1401, styrene-butadiene rubber, terpene resin and low molecular weight polyethylene wax into the mixed oil material obtained in step S2, stirring at a constant temperature for 2 hours after raising the temperature to 180° C., to ...

Embodiment 2

[0037] A novel high temperature resistant non-curing waterproof coating consists of the following components by weight percentage:

[0038] No. 90 asphalt 25%, naphthenic rubber oil 30%, waste tire rubber powder 12%, styrene-butadiene rubber 7%, SBS14011%, terpene resin 5%, fly ash 10%, polyamide wax 5%, low molecular weight poly Vinyl Wax 5%,

[0039] Its preparation method comprises the following steps:

[0040] S1. According to the above formula, weigh each component for later use;

[0041] S2. Pump No. 90 asphalt and naphthenic rubber oil in the molten state into the reaction kettle through the insulation pipeline, and stir until the temperature of the material reaches 150° C. to obtain a mixed oil;

[0042] S3. Putting SBS1401, styrene-butadiene rubber, terpene resin and low molecular weight polyethylene wax into the mixed oil material obtained in step S2, stirring at a constant temperature for 2 hours after raising the temperature to 180° C., to obtain the mixed materi...

Embodiment 3

[0045] A novel high temperature resistant non-curing waterproof coating consists of the following components by weight percentage:

[0046] No. 90 asphalt 30%, naphthenic rubber oil 15%, waste tire rubber powder 20%, styrene-butadiene rubber 5%, SBS14013%, hydrogenated C5 petroleum resin 8%, fly ash 12%, polyamide wax 3%, Low Molecular Weight Polyethylene Wax 4%,

[0047] Its preparation method comprises the following steps:

[0048] S1. According to the above formula, weigh each component for later use;

[0049] S2. Pump No. 90 asphalt and naphthenic rubber oil in the molten state into the reaction kettle through the insulation pipeline, and stir until the temperature of the material reaches 150° C. to obtain a mixed oil;

[0050] S3. Putting SBS1401, styrene-butadiene rubber, hydrogenated C5 petroleum resin and low molecular weight polyethylene wax into the mixed oil material obtained in step S2, stirring at a constant temperature for 2 hours after raising the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com