A brush-shaped block polymer and its synthesis method and application

A synthesis method and technology of block copolymers, which are applied in the field of preparation of brush-like block copolymers, can solve the problems of difficulty in preparing a wide range of photonic crystal materials and complex processes, and achieve obvious temperature responsiveness and great practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

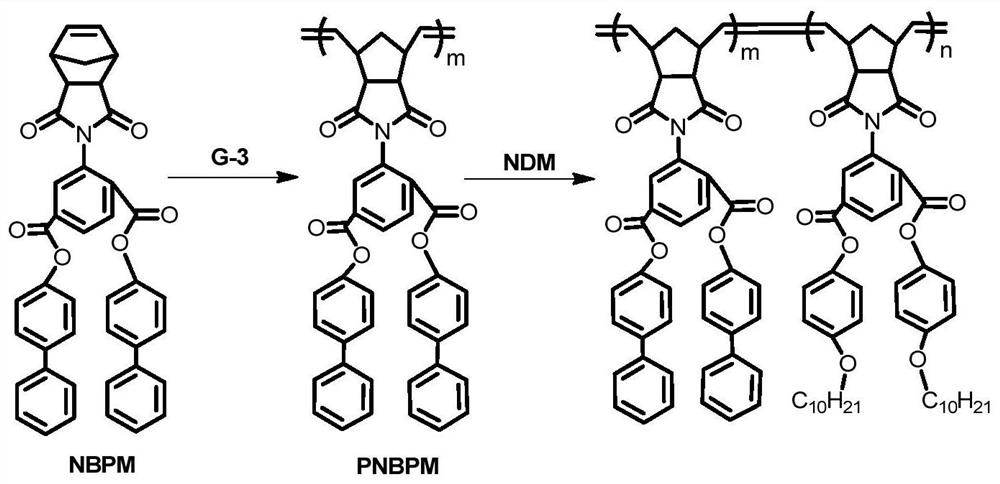

[0038] The preparation method of brush block copolymer BCP1-6: its preparation route is as follows figure 1 as shown,

[0039] The general structural formula of BCP1-6 is:

[0040]

[0041] The synthesis steps of BCP1 (m=200, n=200) are as follows:

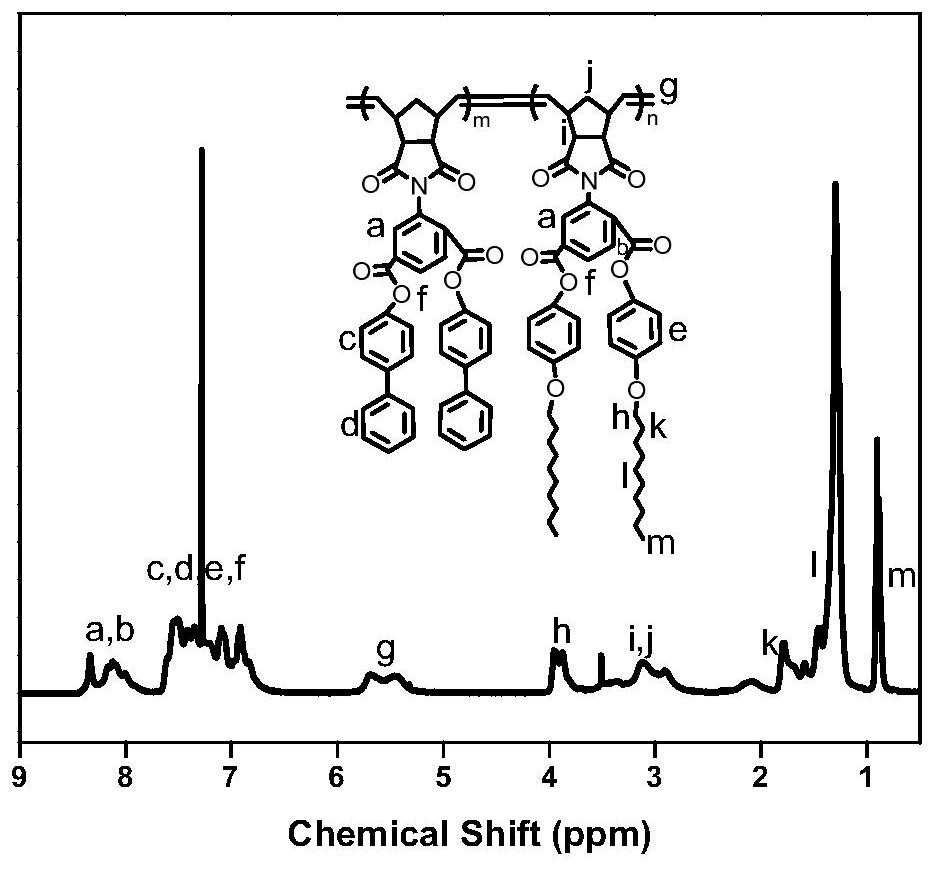

[0042] Add NBPM (57.6mg, 91.2μmol) to 10mL polymerization bottle, 1mL dry dichloromethane, add G-3 (0.41mg, 0.46×10 -3 mmol) in dichloromethane solution 0.1mL, stirred and reacted at room temperature for 30 minutes, then added 1.1mL of dichloromethane solution containing NDM (72.2mg, 91.2μmol) into the above reaction solution to continue the reaction for 1 hour, the entire addition Both reactions were carried out in a glove box. After the reaction was complete, 1 mL of vinyl ether was added to quench the reaction. Remove the glove box, precipitate in anhydrous methanol, centrifuge, and vacuum dry to obtain the brush-like block copolymer BCP1 with a main chain polymerization degree of 400, wherein the polymerization degree o...

Embodiment 2

[0055] The synthesized series of brush-like block copolymers (BCP1-BCP6) solvent volatilization self-assembly and heat treatment conditions:

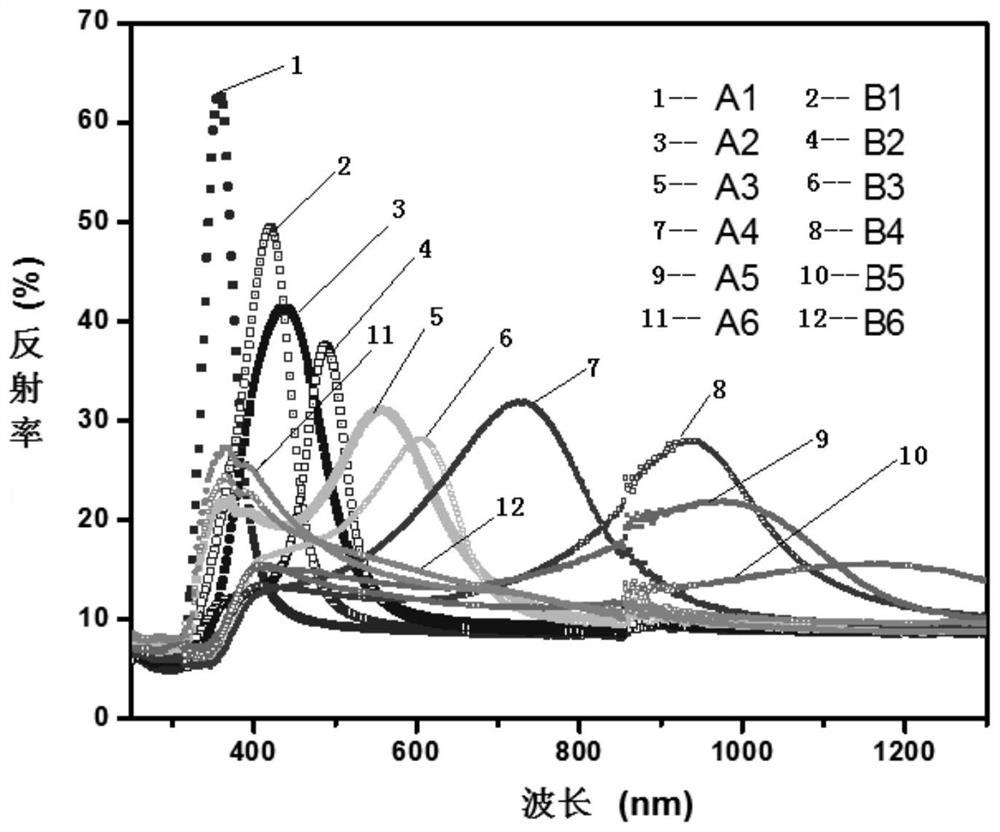

[0056] The synthesized brush-like block copolymers (BCP1-BCP6) were respectively prepared with 10 mg / mL tetrahydrofuran solution, and the mixed solution was applied drop by drop on a clean horizontal glass slide, and six different polymer films were obtained after the solvent evaporated completely. , which is the one-dimensional photonic crystal material. Then the prepared one-dimensional photonic crystal thin film was heat-treated at 130°C for 30 minutes to study its temperature-sensitivity characteristics. Such as figure 2 Shown are the self-assembly pictures of BCP1-BCP6 before and after heat treatment, showing obvious light reflection phenomenon and obvious temperature-sensitive behavior. The self-assembly of BCP1 was dark purple before heating and blue after heating; the self-assembly of BCP2 was blue before heating and bright g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com