Method for obtaining cylinder body temperature by calculating dewatering amount of KLD-2 cut-tobacco drier

A technology of KLD-2 and silk drying machine, which is applied in the field of tobacco processing, can solve the problems of not being better, taking a long time, not knowing computer calculation and regulation, etc., and achieving the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

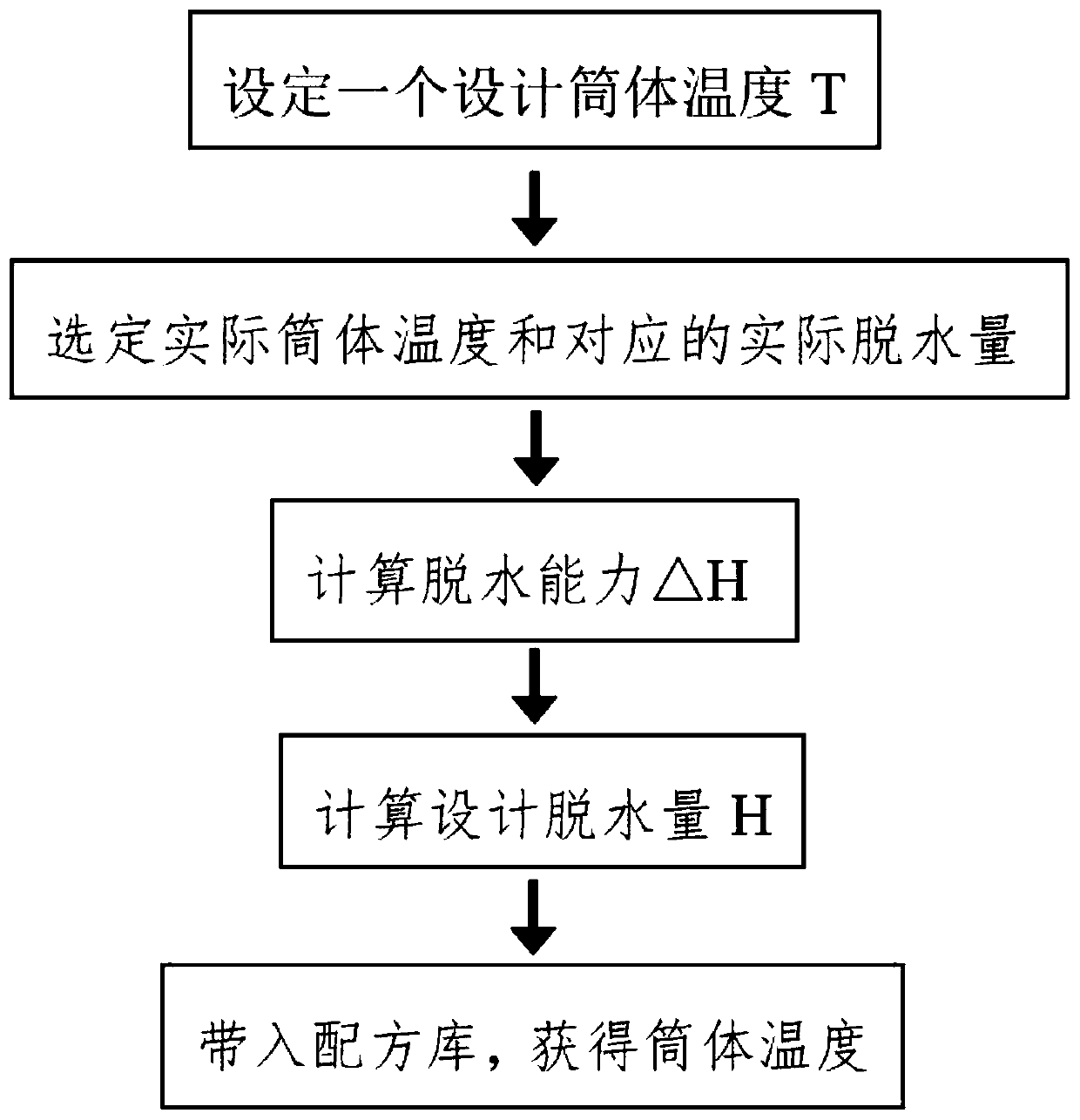

[0034] A method for obtaining cylinder body temperature by calculating the dehydration capacity of KLD-2 silk dryer, comprising the following steps:

[0035] 1. On March 26, 2019, the KLD-2 wire drying machine of the 500kg / h test line was selected;

[0036] 2. Calculation of the relationship between the amount of dehydration and the temperature of the cylinder (application formula: △H=|H1-H2| / |T1-T2|);

[0037] The historical trend graphs of two batches were retrieved in the central control room. In the steady state, the hot air temperature was 115°C; the actual cylinder temperature T1=156°C and the corresponding actual dehydration volume H1=71L / h were obtained, and the actual cylinder temperature T2 =149°C and the corresponding actual dehydration capacity H2=62L / h; calculate the dehydration capacity by the actual cylinder temperature and the actual dehydration capacity △H=|H1-H2| / |T1-T2|:

[0038] That is, △H=(|71-62| / |156-149|)(L / h) / °C=8 / 7(L / h) / °C=1.286(L / h) / °C;

[0039] 3. ...

Embodiment 2

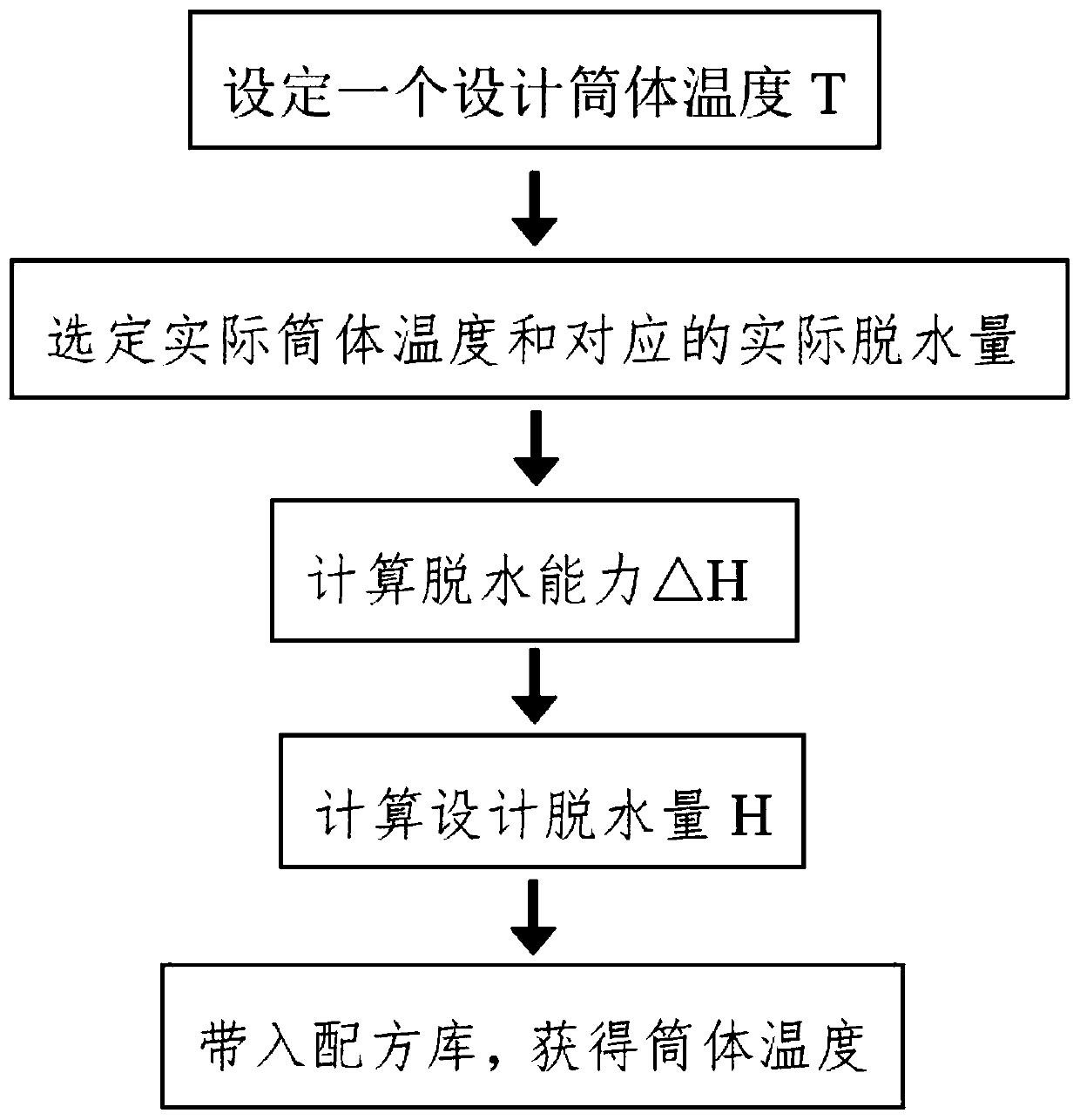

[0048] A method for obtaining cylinder body temperature by calculating the dehydration capacity of KLD-2 silk dryer, comprising the following steps:

[0049] 1. On March 13, 2019, the 3000kg / h KLD-2 wire drying machine of Guiyang Factory was selected;

[0050] 2. Calculation of the relationship between the amount of dehydration and the temperature of the cylinder (application formula: △H=|H1-H2| / |T1-T2|);

[0051] The historical trend charts of two batches were retrieved in the central control room. In the steady state, the hot air temperature was 110°C; the actual cylinder temperature T1=140°C and the corresponding actual dehydration volume H1=287L / h were obtained, and the actual cylinder temperature T2 =143°C and the corresponding actual dehydration amount H2=300L / h. Calculate the dehydration capacity △H=|H1-H2| / |T1-T2| by the actual cylinder temperature and the actual dehydration amount:

[0052] That is, △H=(|287-300| / |140-143|)(L / h) / ℃=13 / 3(L / h) / ℃=4.333(L / h) / ℃;

[0053]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com