Optical interference light source device of current-temperature control semiconductor laser and measurement system thereof

A technology of optical interference and light source device, which is applied in the field of measurement system, can solve the problems of inability to guarantee the working temperature of semiconductor lasers, low heat transfer efficiency, large thermal inertia, etc., achieve convenient detection and control, improve temperature control accuracy, and accelerate heat transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

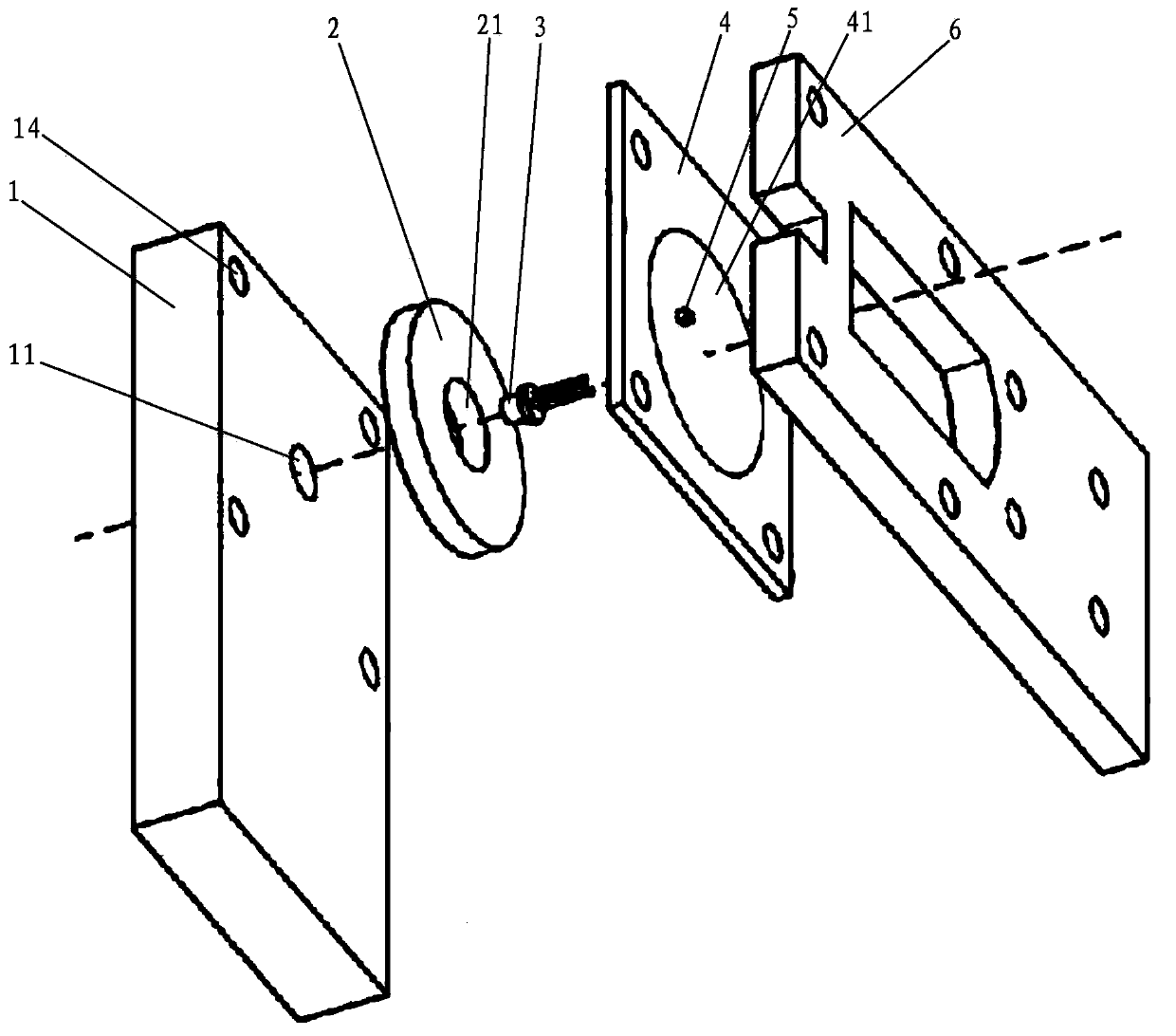

[0029] refer to figure 1 , the present embodiment relates to an optical interference light source device of a current-temperature-controlled semiconductor laser, including a cooling plate 1, an annular semiconductor cooling plate 2, a semiconductor laser 3, a PCB board 4, a thermal sensor 5 and a fixed plate 6, and the PCB board 4 A first circular windowed copper area and a second circular copper area 41 are respectively provided in the center of the two sides, and the first circular windowed copper area is in contact with the second circular copper area 41 through a via hole; the semiconductor laser 3 is electrically connected to the center of the PCB board 4, and the lower end of the casing of the semiconductor laser 3 is connected to the first circular windowed copper area through thermal conductive silicone grease, and the center of the annular semiconductor cooling sheet 2 has a through hole 21, and the annular semiconductor cooling sheet The cooling surface of 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com