Heterojunction photo-anode for driving reduction of carbon dioxide and preparation method and application of heterojunction photo-anode

A carbon dioxide, heterojunction technology, applied in chemical instruments and methods, electrodes, chemical/physical processes, etc., can solve the problems of catalysis efficiency limitation, ineffective use of sunlight, etc., to reduce the recombination rate and promote high efficiency and rapidity. Effect of geomigration, excellent photoelectrochemical (PEC) performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

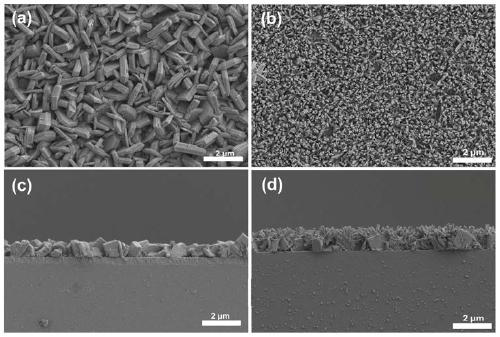

[0025] Embodiment 1, WO 3 / Bi 2 S 3 Fabrication of Heterojunction Photoanodes

[0026] This example prepares relevant photoanode nanomaterials according to the following steps:

[0027] 1) The hydrothermal method of the prior art is used to prepare WO 3 Nanosheet array (Du Ronggui et al., preparation method of tungsten trioxide nanosheet composite photoanode, Chinese patent application number: 201810115207.1), the specific steps are as follows:

[0028] Weigh 0.231g of sodium tungstate dihydrate and stir in 30mL of deionized water until dissolved, add dropwise 10mL of hydrochloric acid (3M) and stir for about 10min, then add 0.2g of ammonium oxalate and 35mL of deionized water and continue stirring for 30min, then place the solution in water In the thermal reaction kettle, after sealing, the hydrothermal reaction was carried out at a temperature of 120 ° C for 6 hours, that is, the vertical growth of WO was prepared on the conductive glass (FTO). 3 ·H 2 O nanosheet array...

Embodiment 2

[0035] Example 2, WO 3 / Bi 2 S 3 Photoelectrochemical performance of heterojunction photoanodes

[0036] With the WO prepared in Example 1 3 Nanosheet photoanodes and WO 3 / Bi 2 S 3 A series of photoelectrochemical performance tests such as photocurrent and impedance were performed on the heterojunction photoanode. The photoelectrochemical performance test is carried out in the electrochemical workstation of the three-electrode system. The prepared photoanode material is the working electrode, the platinum sheet is the counter electrode, the saturated calomel electrode is the reference electrode, and the electrolyte is 0.5M anhydrous sodium sulfate. solution. A xenon lamp was used as the light source during the photoelectric test, and the optical power density of the light source was calibrated to 100mW cm -2 . Test the current density-time curve (I-T) of the sample electrode at a bias voltage of 1.0V; at a bias voltage of 0.8V, the frequency range is 10 -1 to 10 4 ...

Embodiment 3

[0039] Example 3, WO 3 / Bi 2 S 3 Photoelectrocatalytic CO with heterojunction photoanodes 2 Reduction experiment

[0040] With the WO prepared in Example 1 3 Nanosheet photoanodes and WO 3 / Bi 2 S 3 Heterojunction photoanode for photoelectrocatalytic reduction of CO in a photoanode-driven photoelectrochemical system 2 experiment.

[0041] Photoanode-driven photoelectrocatalytic CO 2 The reduction test was carried out in an electrochemical workstation with a three-electrode system. The prepared photoanode material was used as the working electrode, the 1cm×2cm foamed copper was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Photocatalytic CO in an H-type electrolytic cell equipped with a quartz window 2 Reduction experiments, the electrolytic cell consists of two separate compartments, the cathode and the anode, and the anode compartment is filled with 0.2M Na 2 SO 4 solution, while 0.5M KHCO in the cathode co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com