Method for extracting astaxanthin through ionic liquid microemulsion

A technology of ionic liquid and microemulsion, which is applied in organic chemistry and other fields, can solve the problems of potential toxicity of food safety products and serious risks in sustainability, and achieve the effects of protecting biological activity, strong solubility, and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Fresh shrimp shells were washed and freeze-dried at -60°C for 24 hours, then placed in a grinder to grind them into powder, and passed through a 40-mesh sieve to obtain shrimp shell powder for later use.

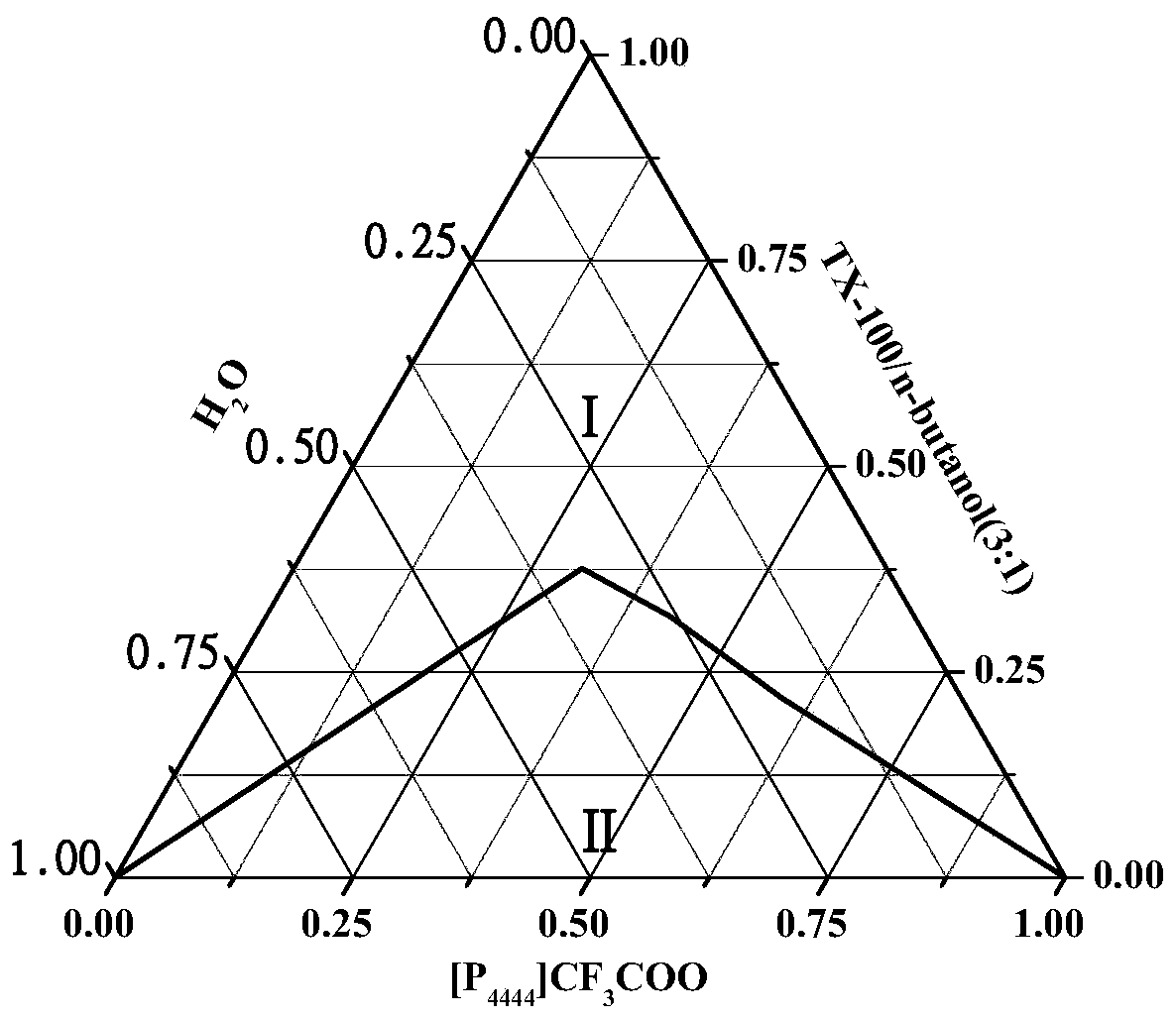

[0052] (2) ionic liquid, emulsifier and distilled water are mixed uniformly to prepare ionic liquid microemulsion, so that the massfraction of ionic liquid in the obtained ionic liquid microemulsion is 12%, the massfraction of emulsifier is 30%, and all the other are distilled water; Wherein , the ionic liquid is tetrabutylphosphine trifluoroacetate, and the emulsifier is uniformly prepared by mixing polyethylene glycol octylphenyl ether and n-butanol at a mass ratio of 3:1.

[0053] (3) Get the shrimp shell powder that 1g step (1) obtains and the ionic liquid microemulsion that 40g step (2) obtains and place in centrifuge tube, stir and mix, then place this centrifuge tube in ultrasonic cleaner, set ultrasonic The power is 50W, ultrasonic at room temperature is u...

Embodiment 2

[0057] (1) Fresh shrimp shells were washed and freeze-dried at -55°C for 36 hours, then placed in a grinder to grind them into powder, and passed through an 80-mesh sieve to obtain shrimp shell powder for later use.

[0058] (2) ionic liquid, emulsifier and distilled water are mixed uniformly to prepare ionic liquid microemulsion, make the massfraction of ionic liquid in the obtained ionic liquid microemulsion be 15%, the massfraction of emulsifier is 50%, all the other are distilled water; Wherein , the ionic liquid is tetrabutylphosphine tetrafluoroborate, and the emulsifier is uniformly prepared by mixing Tween 80 and n-amyl alcohol at a mass ratio of 5:1.

[0059] (3) Get the shrimp shell powder that 1g step (1) obtains and the ionic liquid microemulsion that 60g step (2) obtains and place in the centrifuge tube, stir and mix, then this centrifuge tube is placed in the ultrasonic cleaner, set ultrasonic The power is 70W, the room temperature is ultrasonic for 40min, and un...

Embodiment 3

[0063] (1) Fresh shrimp shells were washed and freeze-dried at -50°C for 48 hours, then placed in a grinder to grind them into powder, and passed through a 120-mesh sieve to obtain shrimp shell powder for later use.

[0064] (2) ionic liquid, emulsifier and distilled water are mixed uniformly to prepare ionic liquid microemulsion, make the massfraction of ionic liquid in the obtained ionic liquid microemulsion be 20%, the massfraction of emulsifier is 40%, all the other are distilled water; Wherein , the ionic liquid is tetrabutylphosphine tetrafluoroborate, and the emulsifier is uniformly prepared by mixing sorbitan monolaurate and ethanol at a mass ratio of 7:1.

[0065] (3) Get the shrimp shell powder that 1g step (1) obtains and the ionic liquid microemulsion that 80g step (2) obtains and place in centrifuge tube, stir and mix, then place this centrifuge tube in ultrasonic cleaner, set ultrasonic The power is 100W, ultrasonic at room temperature is used for 30 minutes, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com