Wide face copper plate of sheet billet hopper-shaped crystallizer and based on transition curve and manufacturing method

A crystallizer and thin slab technology, which is applied in the thin slab funnel-shaped crystallizer wide-faced copper plate and its preparation field, can solve problems such as large billet shell stress, billet shell cracks, and inconstant curve change rate, and achieve high-efficiency heat, reduce Slab stress, the effect of reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] According to the taper curve obtained in the content of the invention, the following takes a thin slab funnel-shaped crystallizer copper plate as an example to illustrate the specific implementation of the invention. The main parameters of the continuous casting machine using the mold copper plate are as follows:

[0118] Case: 1200mm×90mm thin slab

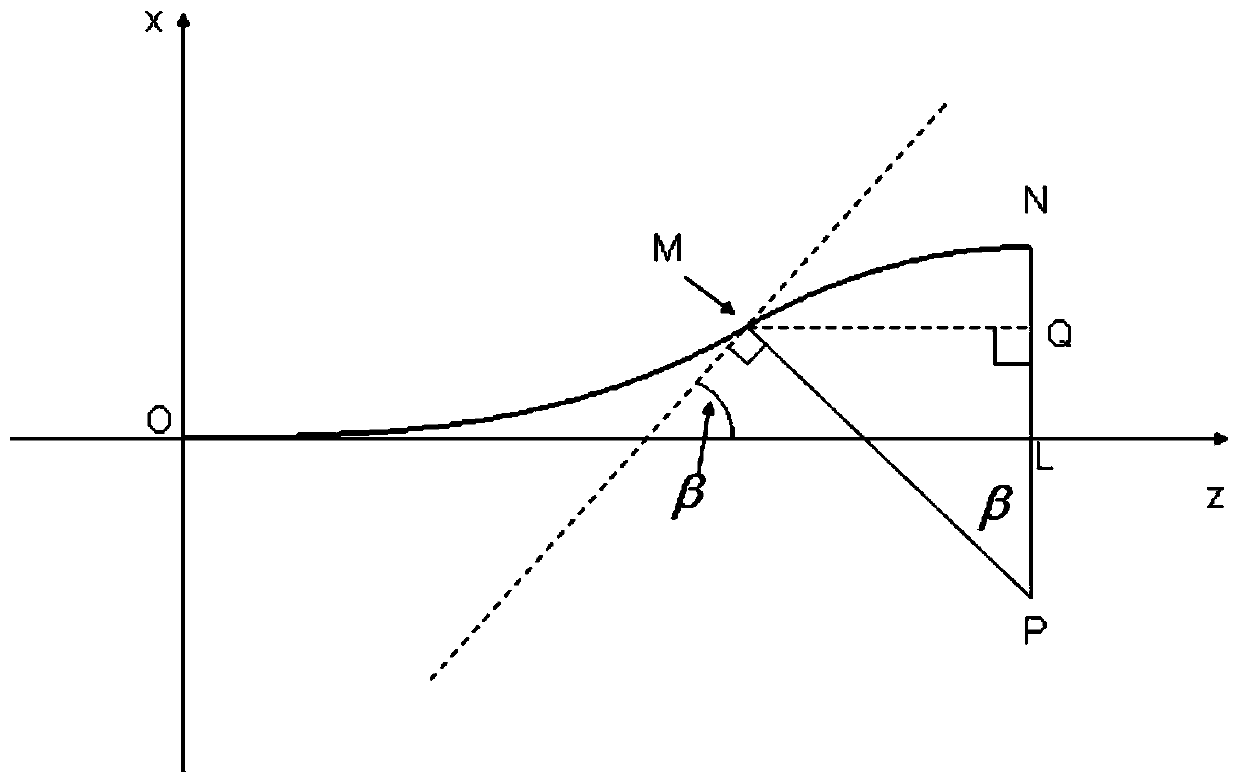

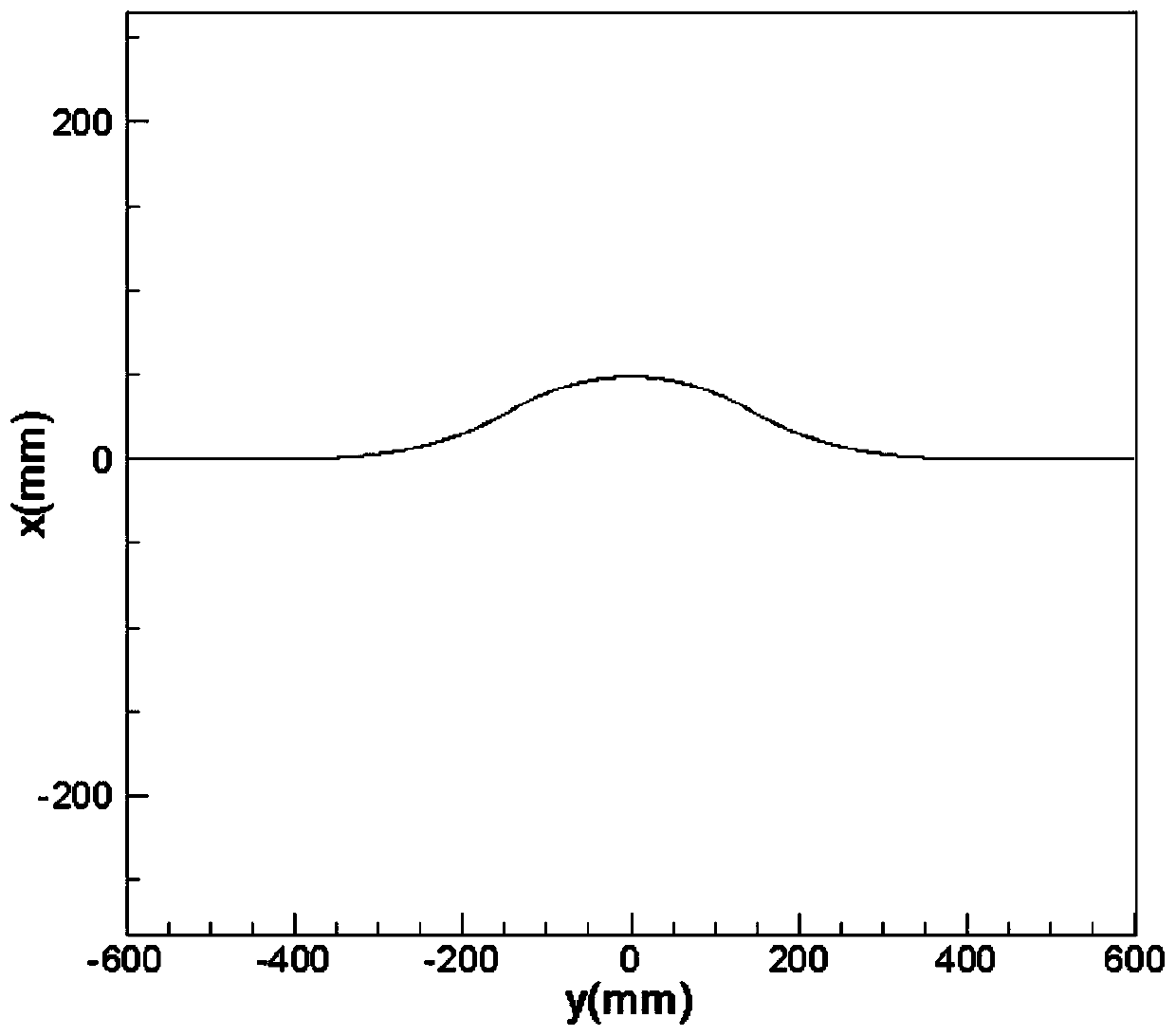

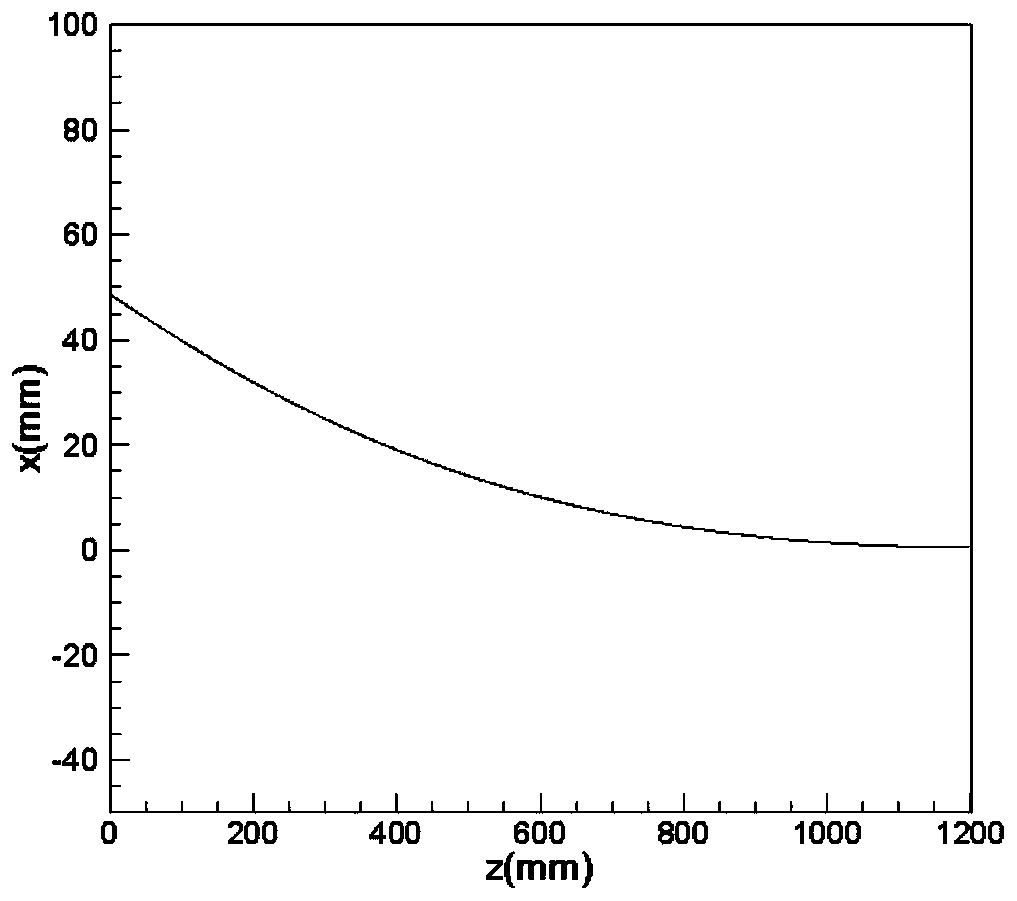

[0119] For the production of 1200mm×90mm thin slabs, considering various factors, the maximum height in the middle of the funnel-shaped curve at the upper mouth of the crystallizer is 48.7141mm; half of the lateral distance of the arc in the funnel area is figure 1 Transverse distance z of medium transition arc OL = 440mm.

[0120] Namely w=1200, wp=h=48.7141, first calculate β and R, and then calculate according to β and R: b1=10.9161, then:

[0121] a=364.656628

[0122] b=1180848.61

[0123] c=-366807250

[0124] d=-3266.04266

[0125] Catchy:

[0126] β=0.570712494

[0127] R=267.5619317

[0128] So as to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com