Strip Cooling Spray Header and Its Installation Structure Between Rolling Mill Stands

A technology for steel strip cooling and rolling mill stand, which is applied in the direction of workpiece cooling device, metal rolling, metal rolling, etc., and can solve the problem of inability to adjust the distance between the nozzle and the injection point, the temperature control effect of the strip body is not obvious, and the impact force of the adjustment mechanism Large and other problems, to achieve the effect of reducing temperature inhomogeneity, avoiding excessive temperature drop, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

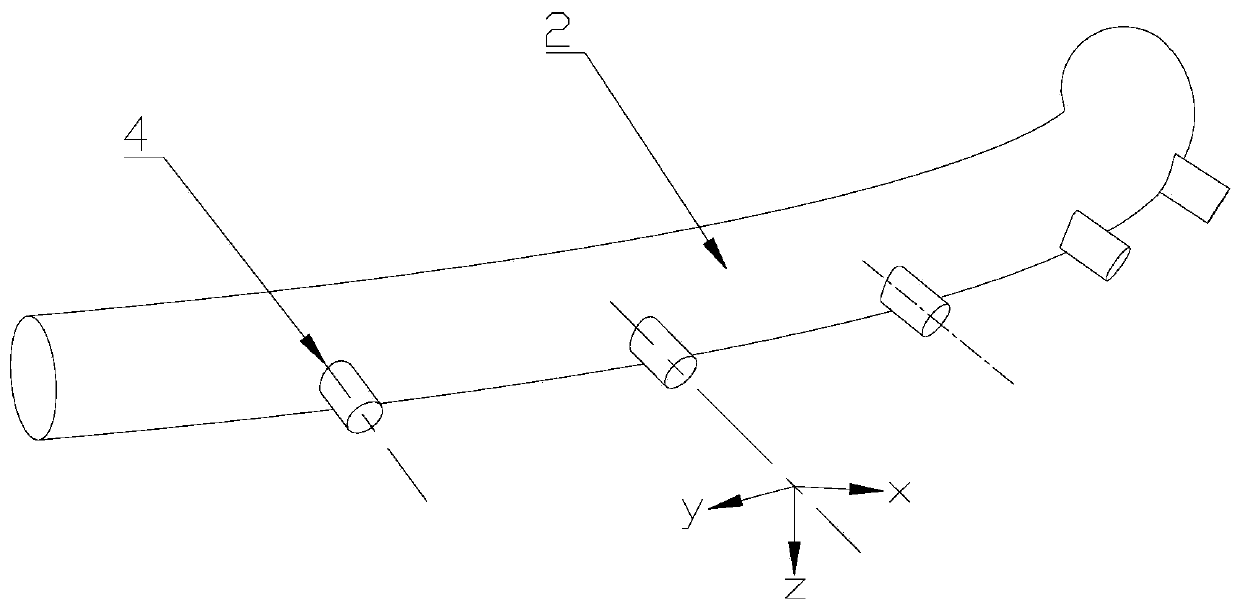

[0026] Such as Figure 1~3 As shown, the cooling spray header for the steel strip between the rolling mill stands designed by the present invention includes a manifold 2 and multiple nozzle tubes 4, among which:

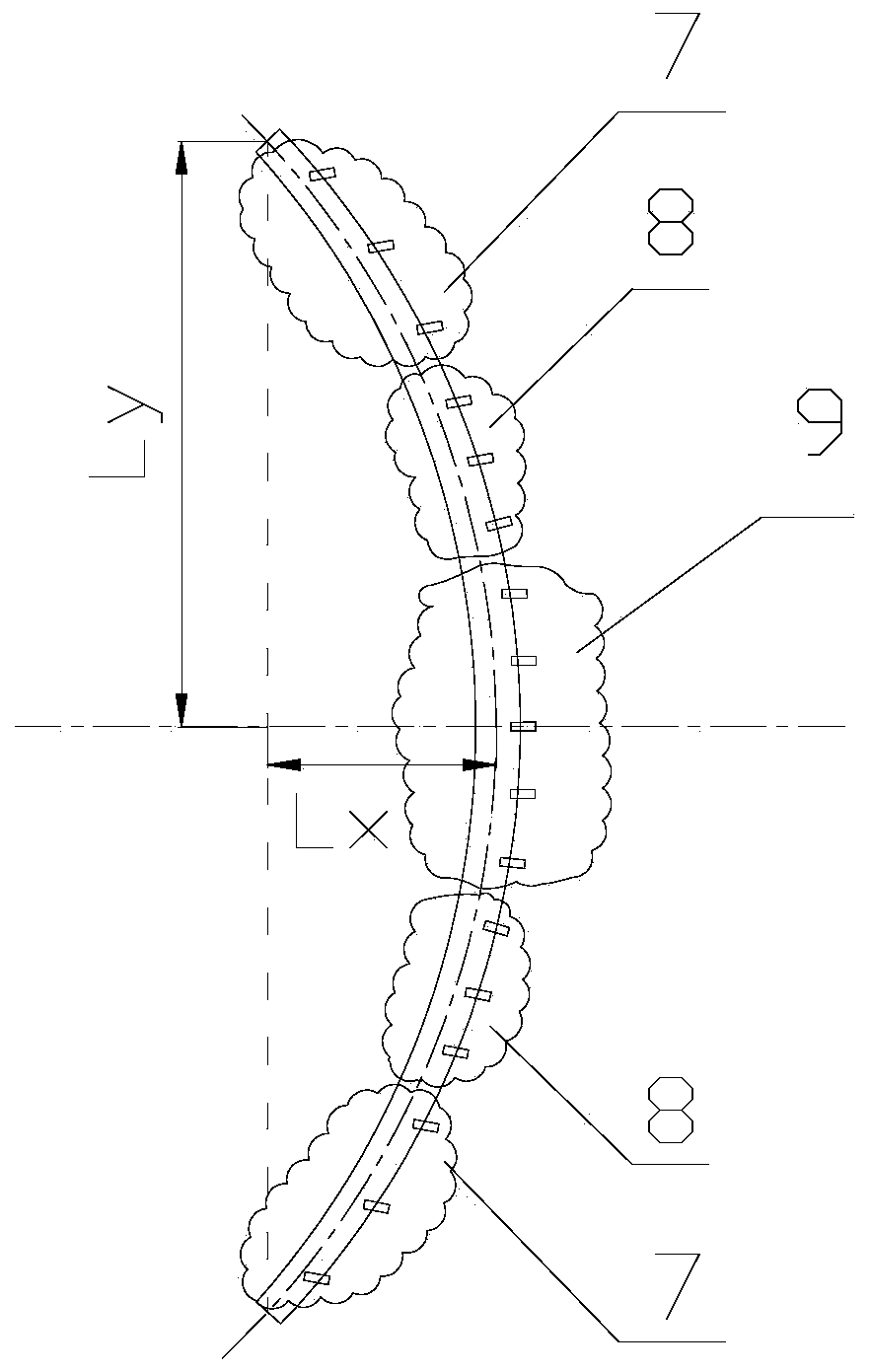

[0027] The shape of the manifold 2 is represented by the central axis of the pipe as an axisymmetric curve intercepted from a conic section, and the length L of the manifold 2 along its axis of symmetry x And its opening width L y Ratio L x / L y =0.05~0.25.

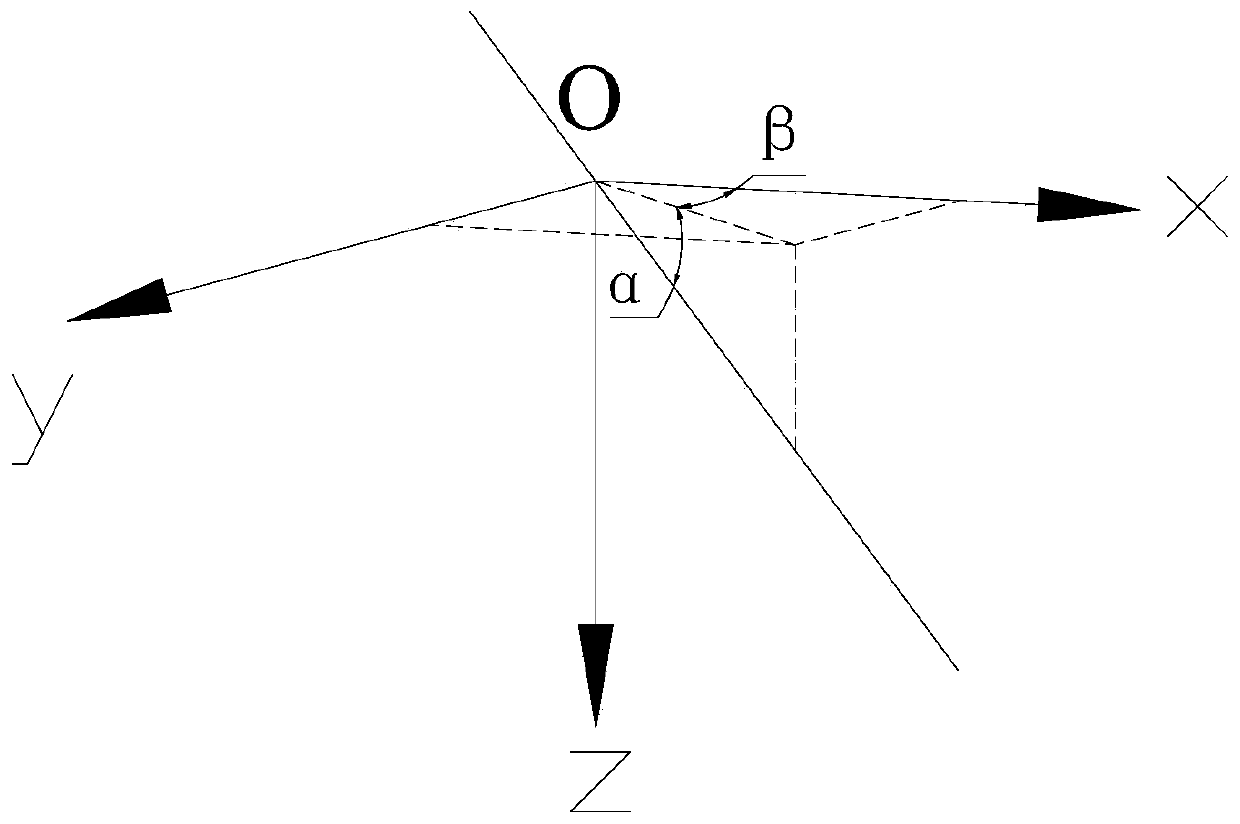

[0028] A plurality of nozzle tubes 4 are arranged along the protruding side of the manifold 2, and are inclined to one side of the plane where the central axis of the manifold 2 is located, so that the central axis of the nozzle at the outlet of the nozzle 4 is the same as the central axis of the manifold 2 The angle between the planes is α=15°~60°.

[0029] The manifold 2 is divided into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com