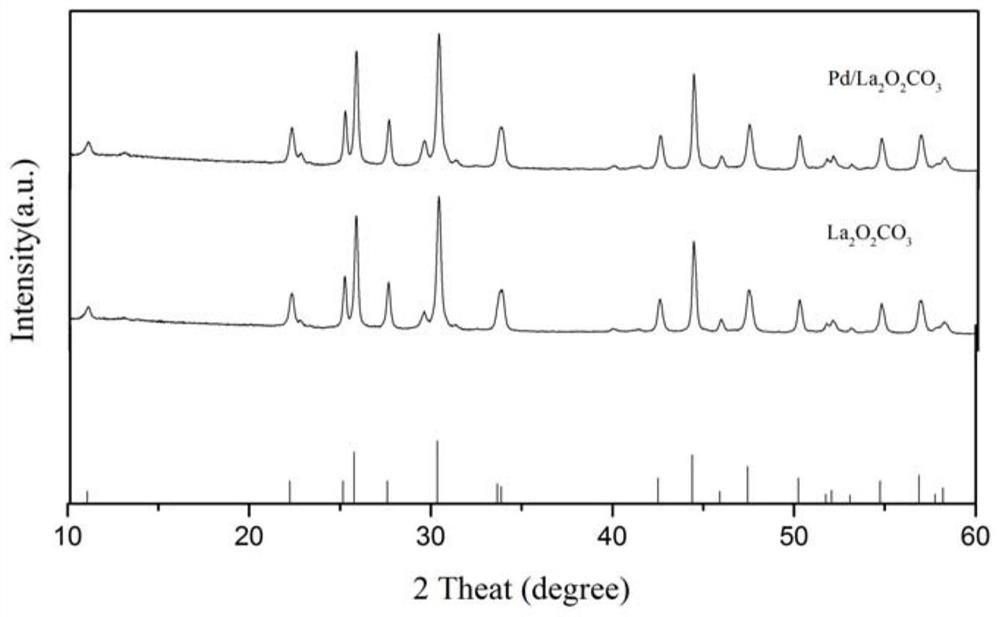

a la 2 o 2 co 3 Preparation method and application of nano-triangular plate-loaded pd catalyst

A triangular sheet and catalyst technology, which is applied in catalyst activation/preparation, organic compound preparation, physical/chemical process catalysts, etc. easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

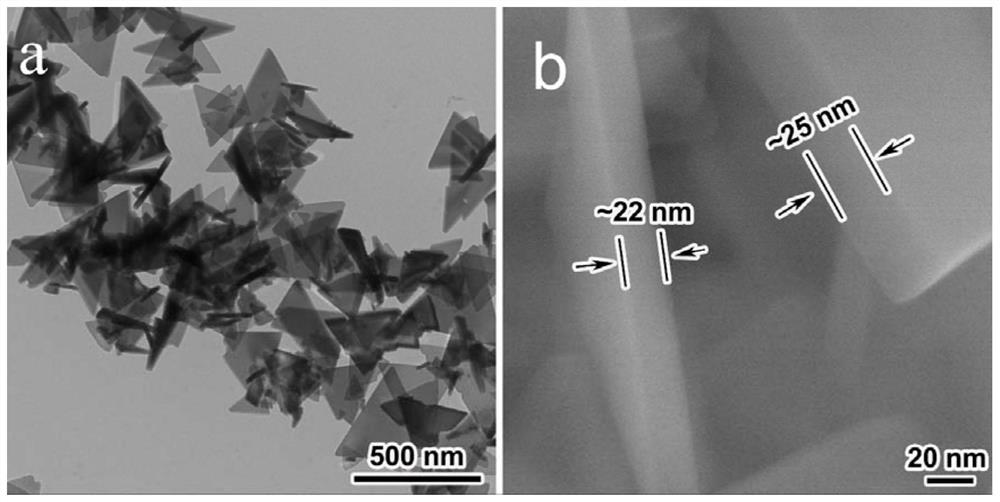

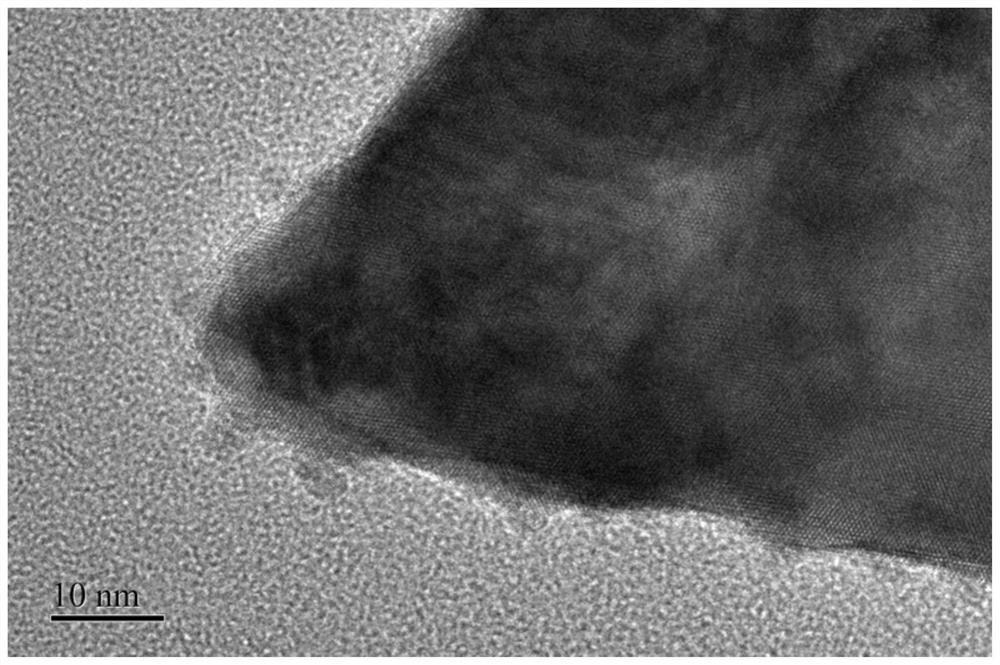

[0030] (1) Nano triangular sheet La 2 o 2 CO 3 making process

[0031] Put 0.56g of potassium carbonate in 40ml of ethylene glycol and heat until completely dissolved to obtain an alkaline solution. Dissolve 1.0 g of lanthanum acetate in 40 ml of deionized water to obtain an aqueous solution of lanthanum acetate, and pour it into an alkaline solution. After stirring for 10 minutes, pour the resulting mixed solution into a hydrothermal reaction kettle, and the liquid volume is the total volume of the hydrothermal kettle. 70% of the volume. Carry out hydrothermal reaction, the temperature of hydrothermal reaction is 453K, and reaction time is 24h. After taking out the hydrothermal kettle, cool to room temperature, filter with suction, wash with deionized water until neutral, and wash with ethanol, put it in a 333K oven, and dry for 12 hours to obtain La(OH) 3 Nanotriangular sheet precursor. This La(OH) 3The precursor of the nanotriangular sheets was calcined in a muffle f...

Embodiment 2

[0040] 1) Nano triangular sheet La 2 o 2 CO 3 The preparation process

[0041] Put 0.56g of potassium carbonate in 40ml of ethylene glycol and heat until completely dissolved to obtain an alkaline solution. Dissolve 1.0g of lanthanum acetate in 40ml of deionized water to obtain an aqueous solution of lanthanum acetate, and pour it into an alkaline solution. After stirring for 10 minutes, pour the resulting mixed solution into a hydrothermal reaction kettle. The volume of the liquid is the total volume of the hydrothermal kettle. 70%. Carry out hydrothermal reaction, the temperature of hydrothermal reaction is 453K, and reaction time is 12h. After taking out the hydrothermal kettle, cool to room temperature, filter with suction, wash with deionized water until neutral, and wash with ethanol, put it in a 333K oven, dry for 12 hours, and roast in a muffle furnace. The roasting temperature is 773K, and the roasting time is for 4h. The obtained sample looks like Figure 5 sh...

Embodiment 3

[0043] 1) Nano triangular sheet La 2 o 2 CO 3 The preparation process

[0044] Put 0.56g of potassium carbonate in 40ml of ethylene glycol and heat until completely dissolved to obtain an alkaline solution. Dissolve 1.0g of lanthanum acetate in 40ml of deionized water to obtain an aqueous solution of lanthanum acetate, and pour it into an alkaline solution. After stirring for 10 minutes, pour the resulting mixed solution into a hydrothermal reaction kettle. The volume of the liquid is the total volume of the hydrothermal kettle. 70%. A hydrothermal reaction is carried out, the temperature of the hydrothermal reaction is 453K, and the reaction time is 48h. After taking out the hydrothermal kettle, cool to room temperature, filter with suction, wash with deionized water until neutral, and wash with ethanol, put it in a 333K oven, dry for 12 hours, and roast in a muffle furnace. The roasting temperature is 773K, and the roasting time is for 4h. The obtained sample looks lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com