Preparation of indium oxide/indium sulfide heterojunction semiconductor material and use of photocatalyst and solar nitrogen fixation application

A technology of photocatalyst and indium oxide, which is applied in the field of photocatalytic materials, can solve the problems of broken semiconductor catalyst quantum efficiency, low recycling rate, and reduced nitrogen fixation efficiency, and achieve good solar nitrogen fixation performance and high quantum efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

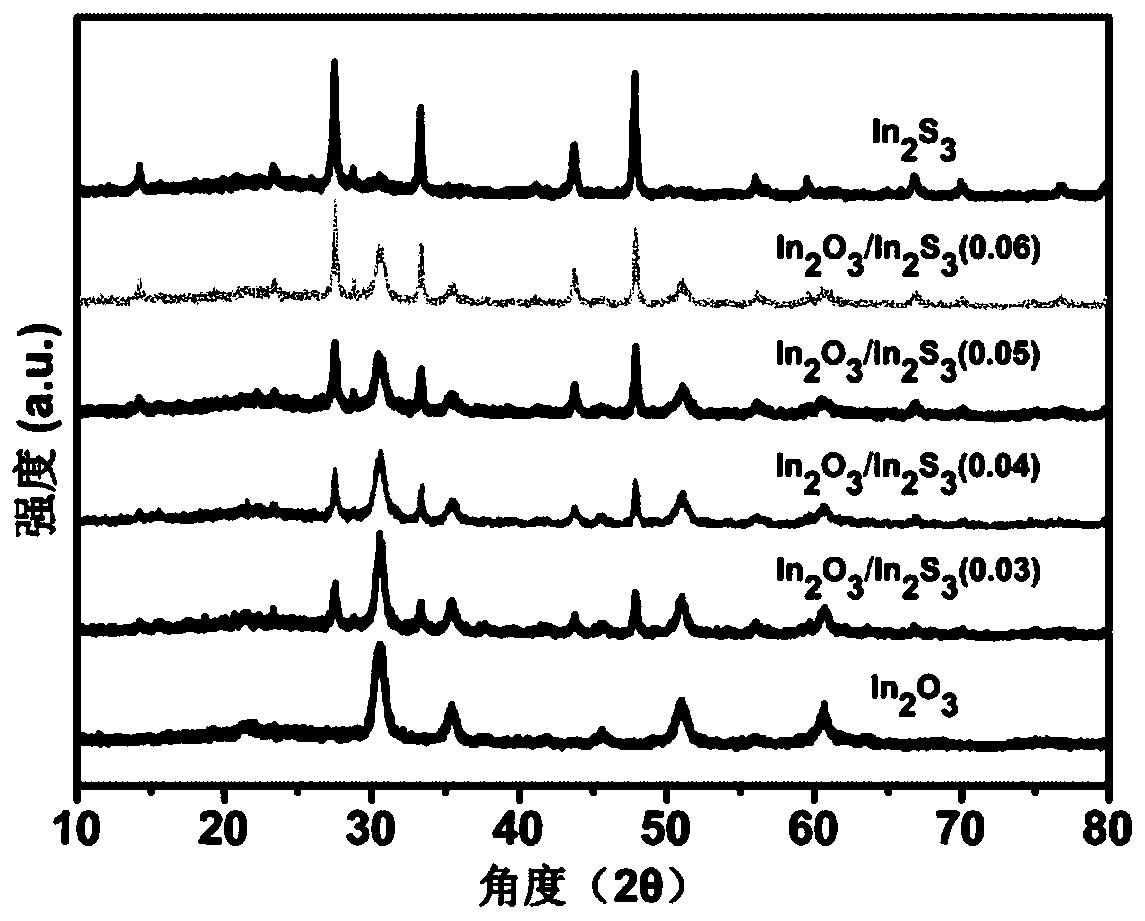

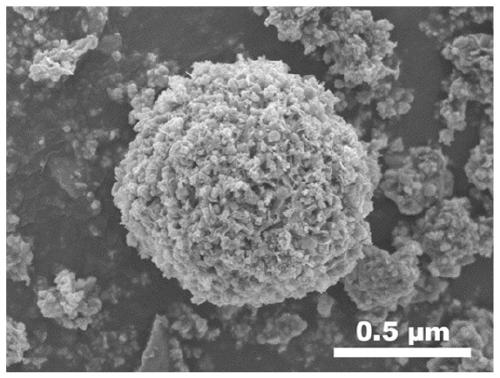

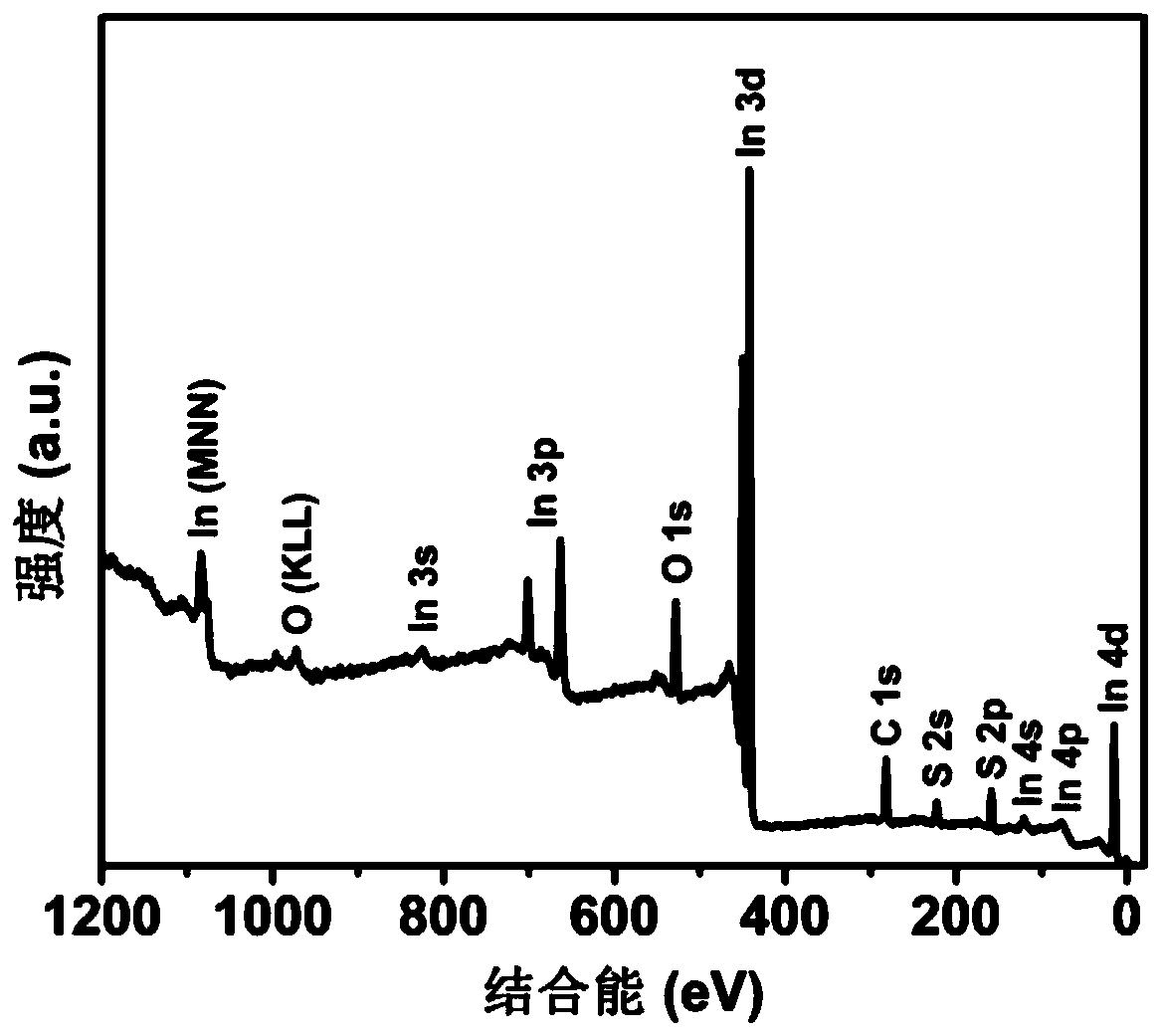

Embodiment 1

[0052] Add 0.2736g of indium chloride tetrahydrate, 0.7627g of sodium lauryl sulfate and 0.2803g of urea into 80mL of aqueous solution, stir thoroughly for 60min to obtain a clear solution, and then transfer the above obtained solution to a 1-2 MPa high-pressure reactor, Carry out constant temperature hydrothermal reaction at 120°C for 12h, cool the product to room temperature, centrifuge and wash 6 times with water and ethanol solution respectively, collect the powder after drying at 60°C, put the obtained product in a muffle furnace, and calcinate at 500°C for 2h . Add 0.1g of the calcined product to 32mL of water, add 0.05g of thioacetamide to the mixed solution after ultrasonication for 30min, stir for 30min, put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 150°C for 5h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the powder t...

Embodiment 2

[0060] Add 0.2736g of indium chloride tetrahydrate, 0.7627g of sodium lauryl sulfate and 0.2803g of urea into 80mL of aqueous solution, stir thoroughly for 60min to obtain a clear solution, and then transfer the above obtained solution to a 1-2 MPa high-pressure reactor, Carry out constant temperature hydrothermal reaction at 120°C for 12h, cool the product to room temperature, centrifuge and wash 6 times with water and ethanol solution respectively, collect the powder after drying at 60°C, put the obtained product into a muffle furnace, and perform calcination at 500°C 2h. Add 0.1g of the calcined product to 32mL of water, add 0.03g of thioacetamide to the mixed solution after ultrasonication for 30min, stir for 30min, put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 150°C for 5h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the p...

Embodiment 3

[0062] Add 0.2736g of indium chloride tetrahydrate, 0.7627g of sodium lauryl sulfate and 0.2803g of urea into 80mL of aqueous solution, stir thoroughly for 60min to obtain a clear solution, and then transfer the above obtained solution to a 1-2 MPa high-pressure reactor, Carry out constant temperature hydrothermal reaction at 120°C for 12h, cool the product to room temperature, centrifuge and wash 6 times with water and ethanol solution respectively, collect powder after drying at 60°C, put the obtained product into a muffle furnace, and perform calcination at 500°C 2h. Add 0.1g of the calcined product to 32mL of water, add 0.04g of thioacetamide to the mixed solution after ultrasonication for 30min, stir for 30min, put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 150°C for 5h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com