Solar nitrogen fixation method and application of hydrotreated yttrium-deposited yttrium bromide

A technology of solar energy and nitrogen fixation, which is applied in the field of photocatalytic materials, can solve the problems of low solar nitrogen fixation ability, and achieve high quantum efficiency, excellent solar nitrogen fixation performance, and good solar nitrogen fixation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 0.24g of bismuth nitrate pentahydrate and 0.102g of sodium bromide into 10mL of ethylene glycol solution, stir thoroughly for 20min until the solution becomes clear, then add 25mL of isopropanol solution, stir the mixed solution for 30min, add 1mL of thiourea solution, and stir for 5min Put it into a 1-2MPa high-pressure reactor, and conduct a constant temperature hydrothermal reaction at 160°C for 12 hours. The product was cooled to room temperature for centrifugation, washed with water and ethanol solution for 6 times, and dried at 60°C to collect the powder. Calcined at 200 °C and 360 mL / min hydrogen atmosphere for 4 h to obtain the final product H-Bi@BiOBr.

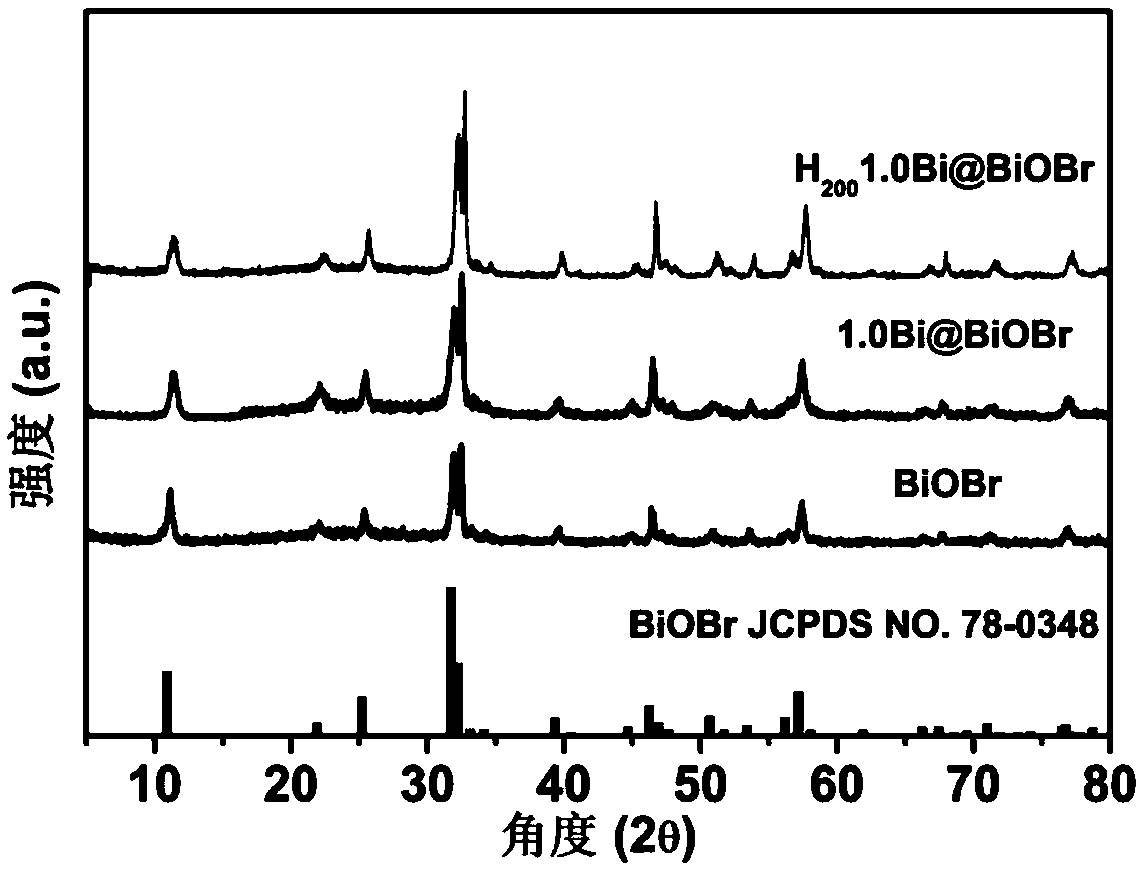

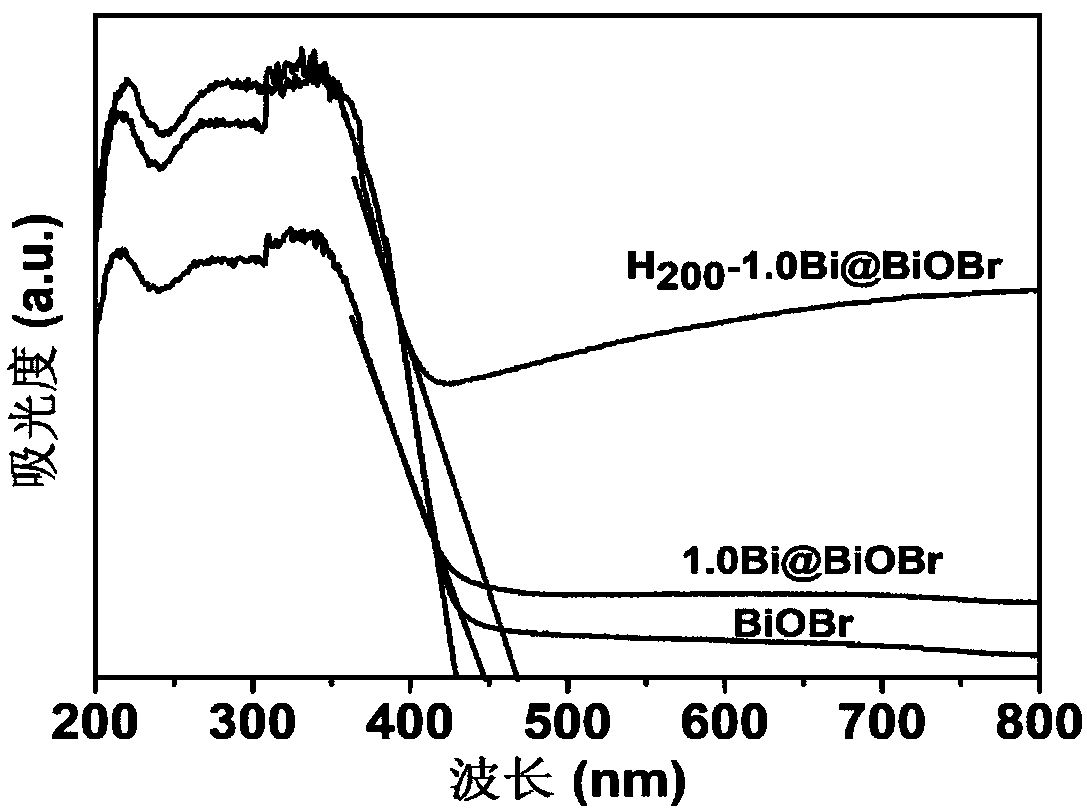

[0046] figure 1 It is the XRD diffraction pattern of the H-Bi@BiOBr photocatalyst obtained in this example, and compared with the PDF standard card, it is known that the obtained BiOBr is a tetragonal phase.

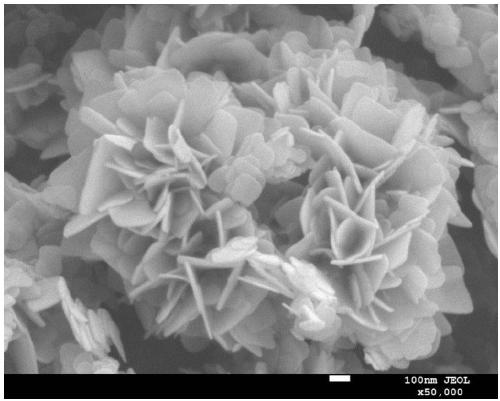

[0047] figure 2 It is the scanning electron microscope image of the H-Bi@BiOBr photocatalyst o...

Embodiment 2

[0053] Add 0.24g of bismuth nitrate pentahydrate and 0.102g of sodium bromide into 10mL of ethylene glycol solution, stir thoroughly for 20min until the solution becomes clear, then add 25mL of isopropanol solution, stir the mixed solution for 30min, add 1mL of thiourea solution, and stir for 5min Then put it into a 1-2MPa high-pressure reactor, and carry out a constant temperature hydrothermal reaction at 160°C for 12 hours. The product was cooled to room temperature for centrifugation, washed with water and ethanol solution for 6 times, and dried at 60°C to collect the powder. Calcined at 250 °C and 360 mL / min hydrogen atmosphere for 4 h, the final product H-Bi@BiOBr was obtained.

Embodiment 3

[0055] Add 0.24g of bismuth nitrate pentahydrate and 0.102g of sodium bromide into 10mL of ethylene glycol solution, stir thoroughly for 20min until the solution becomes clear, then add 25mL of isopropanol solution, stir the mixed solution for 30min, add 1mL of thiourea solution, and stir for 5min Then put it into a 1-2MPa high-pressure reactor, and carry out a constant temperature hydrothermal reaction at 160°C for 12 hours. The product was cooled to room temperature for centrifugation, washed with water and ethanol solution for 6 times, and dried at 60°C to collect the powder. Calcined at 150 °C and 360 mL / min hydrogen atmosphere for 4 h to obtain the final product H-Bi@BiOBr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com