High-throughput positively-charged acid-resistant nanofiltration membrane as well as preparation method and application thereof

A positively charged and acid-resistant technology, which is applied in the field of membrane preparation, can solve the problems of low flux and achieve the effects of simple preparation method, improved flux and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention discloses a method for preparing a high-throughput positively charged acid-resistant nanofiltration membrane, which is characterized in that the preparation method includes the following steps:

[0019] S1: Immerse the ultrafiltration basement membrane in the prepared aqueous phase solution to react, and obtain the ultrafiltration basement membrane 1 after drying;

[0020] S2: immerse ultrafiltration base membrane 1 into the oil phase solution to react to obtain ultrafiltration base membrane 2;

[0021] S3: A high-throughput positively charged and acid-resistant nanofiltration membrane is obtained after two heat treatments of the ultrafiltration base membrane.

[0022] Wherein, the heat treatment temperature in the step S3 is 20-100° C., for example, 70° C., and the heat treatment time is 1 min-120 min, for example, 5 min.

[0023] Wherein, the steps S1-S3 are all reacted under normal pressure.

[0024] Wherein, after the step S3 is finished, it is rinse...

Embodiment 1

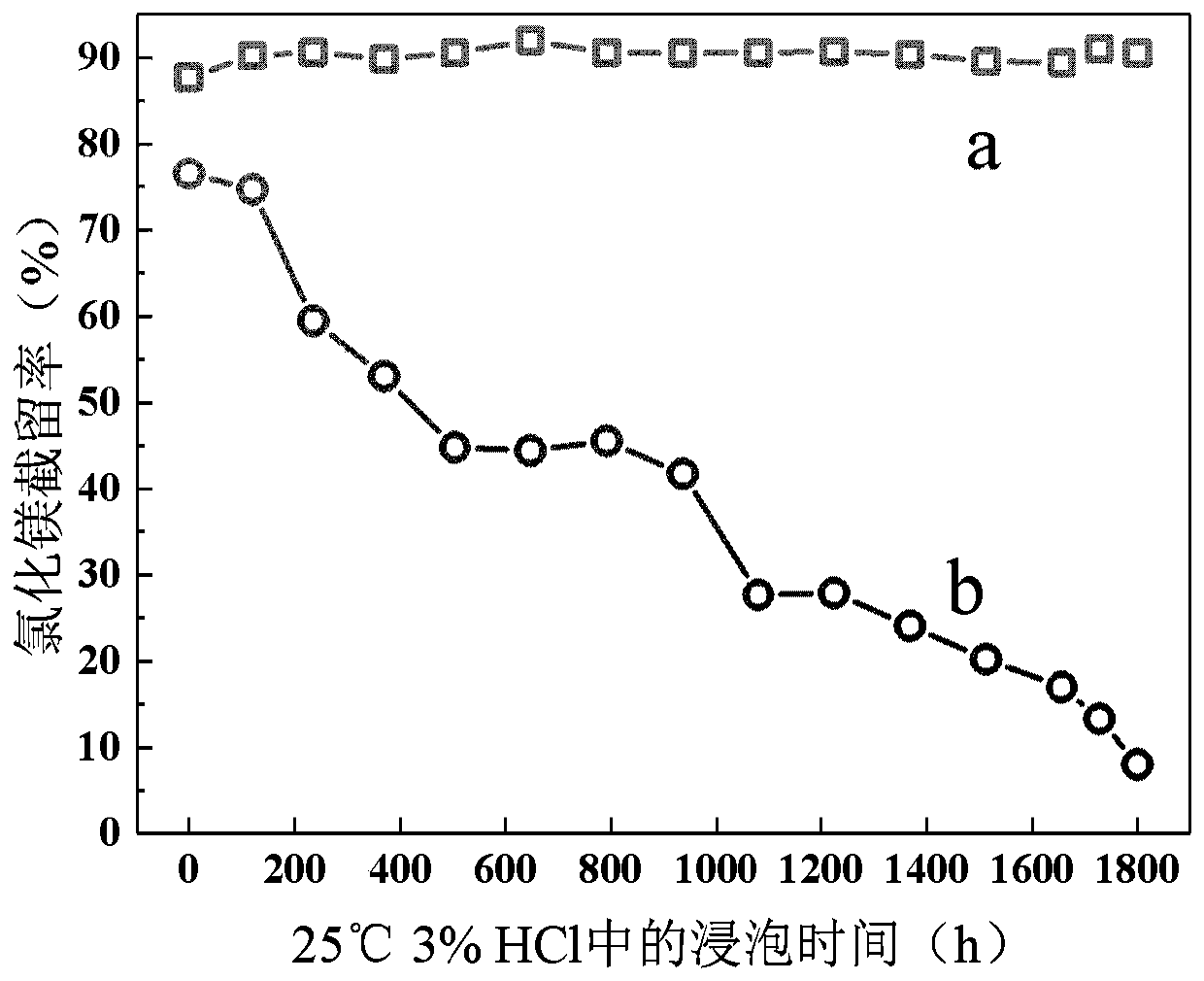

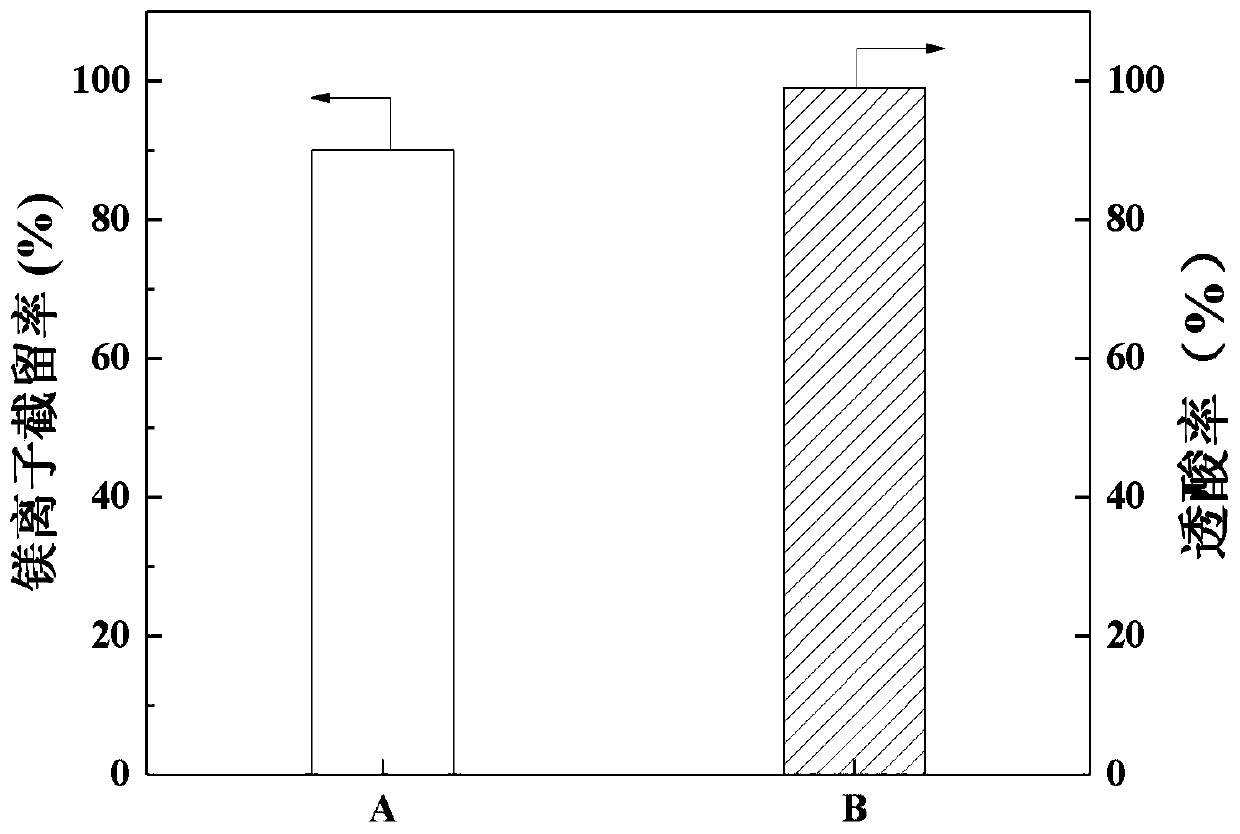

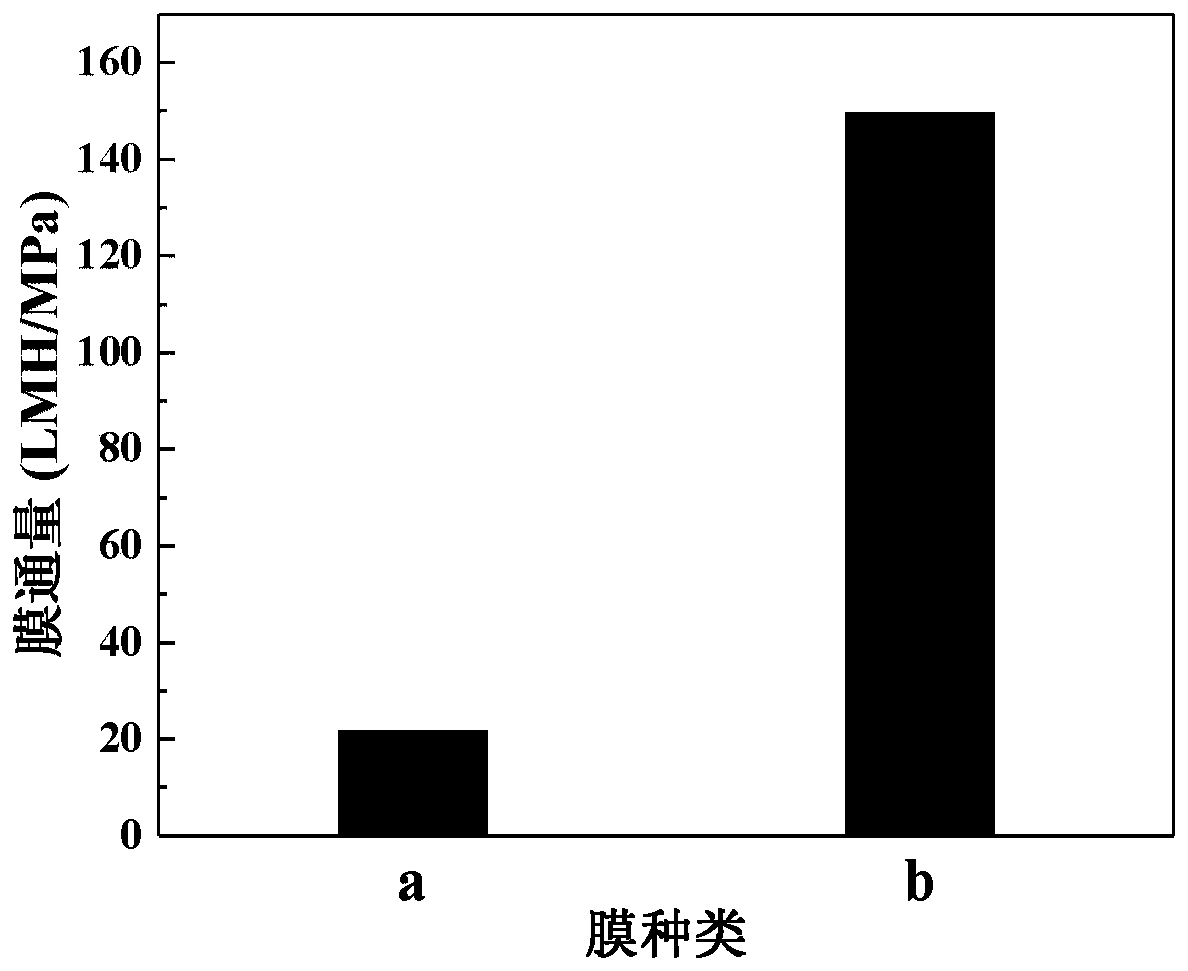

[0068] Weigh 5g of polyethylene amine with a molecular weight of 1800, 1.0g of triethylamine, 0.15g of sodium dodecylsulfonate, add deionized water to 500ml, fully disperse and stir for 12 hours; weigh 0.1g of trimer For cyanogen chloride, dissolve it in 500ml of n-hexane solvent and stir it fully for 12 hours; soak the polyethersulfone ultrafiltration membrane soaked in deionized water in the aqueous phase solution for 10 minutes, take it out and dry it in the air at 25°C It was immersed in the oil phase solution for 2 minutes, and it was heat treated at 30°C for 120 minutes, and then cleaned with deionized water. At room temperature, its flux was measured, which was 40LMH / MPa, and its response to 2g / LMgCl was measured. 2 The cut-off rate is 91%, and the Zeta potential of its surface is 16mV, this high-throughput positively charged acid-proof nanofiltration membrane is soaked in 25 ℃, 3wt% hydrochloric acid, and measures its to 2g / LMgCl 2 The curve graph of the rejection rate...

Embodiment 2

[0071] Weigh 1.25g polyethyleneimine with molecular weights of 600, 1800, 10000, 25000, 1.0g sodium hydroxide, 0.15g sodium dodecylbenzenesulfonate, add deionized water to 500ml, fully disperse and stir them 12 hours; Weigh 0.025g of cyanuric chloride, dissolve it in 500ml of n-hexane solvent, fully stir for 12 hours; soak the polysulfone ultrafiltration membrane soaked in deionized water in the aqueous phase solution for 10min, take it out and let it dry Dry, immerse it in the oil phase solution at 25°C for 3 minutes, heat it at 70°C for 5 minutes, then wash it with deionized water, measure its flux at room temperature, it is 80LMH / MPa, measure its effect on 2 / LMgCl 2 The rejection rate is 92%, and the Zeta potential of its surface is 26mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com