A kind of hemt epitaxial structure and preparation method thereof

An epitaxial structure and nano-nickel technology, which is applied in the field of HEMT epitaxial structure and its preparation, can solve the problems affecting the quality of HEMT, the quality of GaN layer crystal is not good enough, and the quality is not ideal, so as to improve the crystal quality, improve the quality, and improve the material activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

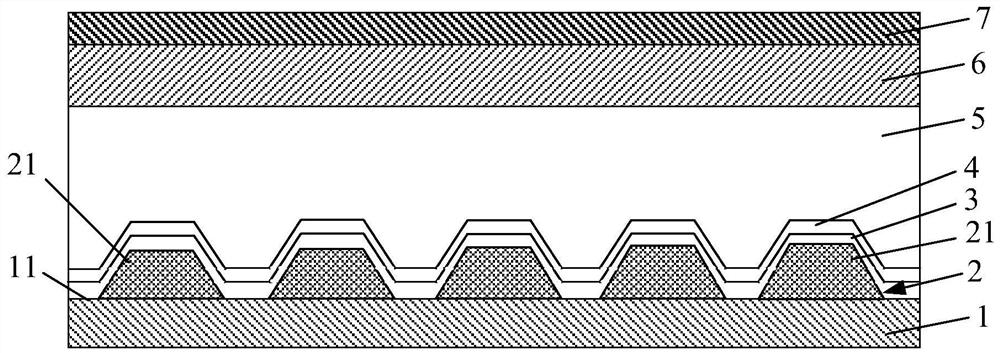

[0031] figure 1 It is a structural schematic diagram of a HEMT epitaxial structure provided by an embodiment of the present invention, such as figure 1 As shown, the HEMT epitaxial structure includes a substrate 1 and a nano-nickel layer 2 , an AlN layer 3 , an AlGaN buffer layer 4 , a GaN layer 5 , an AlGaN barrier layer 6 and a GaN capping layer 7 sequentially stacked on the substrate 1 .

[0032] The nano-nickel layer 2 includes a plurality of island-like structures 21 arranged on the substrate 1, and the plurality of island-like structures 21 are distributed on the substrate 1, and one surface of the layered nano-nickel layer 2 of the substrate 1 is the first surface 11. The projections of the island structures 21 on the first sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com