Method for preparing carbon dioxide adsorbent ceramic by template method

A carbon dioxide and adsorbent technology, which is applied in the field of carbon dioxide adsorbent ceramics prepared by the template method, can solve the problems of low adsorption capacity and low adsorption rate of lithium zirconate, achieve strong carbon dioxide adsorption capacity, promote gelation process, and high material activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

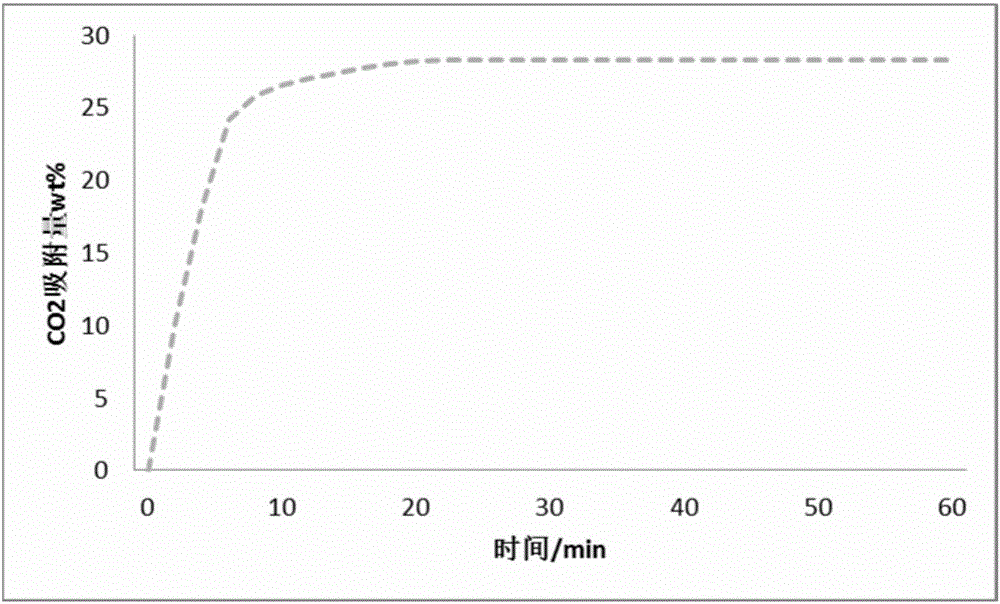

Image

Examples

Embodiment 1

[0029] A method for preparing carbon dioxide adsorbent ceramics by a template method, comprising the following preparation steps:

[0030] (1) prepare materials, zirconium source is zirconium oxychloride octahydrate, and lithium source is lithium nitrate; Catalyst is acidic catalyst; Lye is ammoniacal liquor; Binding agent is glycerol; Acrylamide;

[0031] (2) Dissolve the zirconium source, lithium source, catalyst, binder, and templating agent in deionized water according to a certain ratio, then slowly add lye, and stir at 80°C for 3 hours to form a transparent sol;

[0032] (3) Then raise the temperature to 85°C, add a coagulation accelerator to obtain a gel precursor;

[0033] (4) Grind and disperse the lithium zirconate precursor in a mortar, add activated carbon, grind again, and then carry out cold isostatic pressing. Secondary sintering at 850°C for 2 hours, followed by three sintering at 850°C for 2 hours to obtain carbon dioxide adsorbent ceramics.

[0034] The ac...

Embodiment 2

[0038] A method for preparing carbon dioxide adsorbent ceramics by a template method, comprising the following preparation steps:

[0039] (1) prepare materials, zirconium source is zirconium oxychloride octahydrate, and lithium source is lithium nitrate; Catalyst is acidic catalyst; Lye is ammoniacal liquor; Binding agent is glycerol; Acrylamide;

[0040] (2) Dissolve the zirconium source, lithium source, catalyst, binder, and templating agent in deionized water according to a certain ratio, then slowly add lye, and stir at 80°C for 3 hours to form a transparent sol;

[0041] (3) Then raise the temperature to 85°C, add a coagulation accelerator to obtain a gel precursor;

[0042] (4) Grind and disperse the lithium zirconate precursor in a mortar, add activated carbon, grind again, and then carry out cold isostatic pressing. Secondary sintering at 850°C for 2 hours, followed by three sintering at 850°C for 2 hours to obtain carbon dioxide adsorbent ceramics.

[0043] The ac...

Embodiment 3

[0047] A method for preparing carbon dioxide adsorbent ceramics by a template method, comprising the following preparation steps:

[0048] (1) prepare materials, zirconium source is zirconium oxychloride octahydrate, and lithium source is lithium nitrate; Catalyst is acidic catalyst; Lye is ammoniacal liquor; Binding agent is glycerol; Acrylamide;

[0049] (2) Dissolve the zirconium source, lithium source, catalyst, binder, and templating agent in deionized water according to a certain ratio, then slowly add lye, and stir at 80°C for 3 hours to form a transparent sol;

[0050] (3) Then raise the temperature to 85°C, add a coagulation accelerator to obtain a gel precursor;

[0051] (4) Grind and disperse the lithium zirconate precursor in a mortar, add activated carbon, grind again, and then carry out cold isostatic pressing. Secondary sintering at 900°C for 2 hours, followed by three sintering at 900°C for 2 hours to obtain carbon dioxide adsorbent ceramics.

[0052] The ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com