Sewage treatment system in chemical fiber factory

A sewage treatment system and chemical fiber technology, applied in biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as incomplete treatment, impact on water resources, and inconvenience in treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

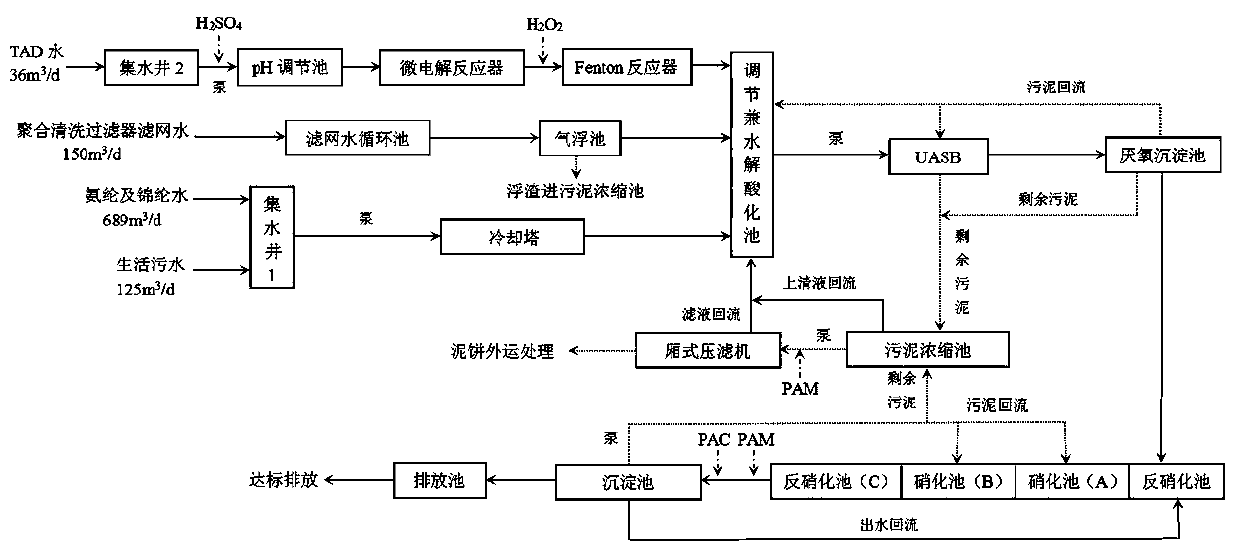

Method used

Image

Examples

Embodiment

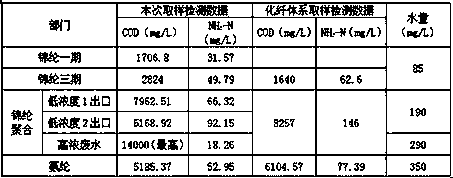

[0024] 1.1 Raw water quality

[0025] According to the relevant information provided by the owner, the waste water contains spandex, nylon water, polymer cleaning filter screen water and TAD water. The raw water quality parameters after sorting are shown in Table 1-1:

[0026] Table 1-1 Raw water quality table

[0027]

[0028] Polymerization cleaning filter screen water volume is 150m 3 / d, in which the maximum suspended solids index reaches 3500 mg / L. Nylon polymerization drainage also contains a stream of TAD water, the water volume is 36m 3 / d, containing TAD is 95kg.

[0029] 1.2 Wastewater source and water quality and quantity

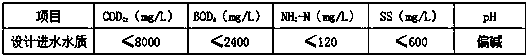

[0030] The wastewater sources of this project are mainly spandex water, nylon water, polymer cleaning filter screen water, TAD water and domestic sewage, and the designed wastewater treatment capacity is 1000m 3 / d.

[0031] Among them, the design water volume of domestic sewage is calculated on the basis of 500 workers, and the daily wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com