A method for preparing condensed milk with caramel flavor

A technology of condensed milk and caramel, applied in dairy products, milk preparations, applications, etc., to achieve the effect of increasing sweetness, increasing food calories, and saving Maillard reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A method for preparing condensed milk with a caramel flavor, at least including the following steps (by mass percentage): (1) Raw milk preparation; raw milk filtering, milk cleaning, adding sucrose syrup dissolved at 60°C (solid objects) 15%;

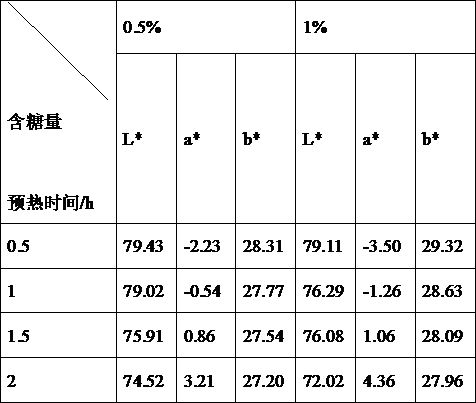

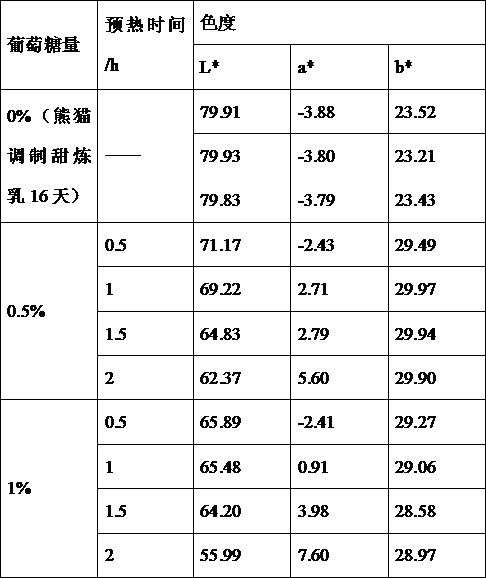

[0021] (2) Add sugar: add 0.25% glucose (solid content) to the solution;

[0022] (3) Lactase hydrolysis: add 100000U / g lactase 0.3%, enzymatic hydrolysis for 1h;

[0023] (4) Protease hydrolysis: add 100,000U / g of neutral protease, when the amount of protease added is 0.02%-0.10%, the temperature is controlled at 30°C for 0.5 h;

[0024] (5) Homogenization: the pressure is controlled at 20MPa;

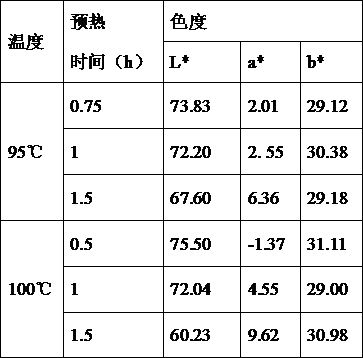

[0025] (6) Pre-sterilization: heat preservation at 95°C for 50 minutes to make the product have browning Maillard reaction;

[0026] (7) Concentration: The pressure is controlled at 0.09Mpa, the temperature is 50°C, and the three-effect concentration is carried out to a solid content of 65%.

[0027] (8) Homogeneous: the p...

Embodiment 2

[0031] Example 2: A method for preparing condensed milk with a caramel flavor, at least including the following steps (by mass percentage): (1) Raw milk preparation; fresh milk filtering, milk cleaning, adding sucrose syrup dissolved at 65°C (solid objects) 16%;

[0032] (2) Add sugar: add 1.0% glucose (solid content) to the solution;

[0033] (3) Lactase hydrolysis: add 300000U / g lactase 0.3%, enzymatic hydrolysis for 2 hours;

[0034] (4) Protease hydrolysis: Add 100,000U / g of neutral protease, when the amount of protease added is 0.02%-0.10%, the temperature is controlled at 40°C for 1 hour;

[0035] (5) Homogenization: the pressure is controlled at 16MPa;

[0036] (6) Pre-sterilization: heat preservation at 105°C for 60 minutes to make the product have browning Maillard reaction;

[0037] (7) Concentration: The pressure is controlled at 0.1Mpa, the temperature is 55°C, and the three-effect concentration is carried out to a solid content of 70%.

[0038] (8) Homogeneous...

Embodiment 3

[0042] Example 3: A method for preparing condensed milk with a caramel flavor, at least including the following steps (by mass percentage): (1) Raw milk preparation; raw milk filtering, milk cleaning, adding sucrose syrup dissolved at 60°C (solid objects) 15%;

[0043] (2) Adding sugar: Add 0.25% fructose syrup (solid content) to the solution;

[0044] (3) Lactase hydrolysis: add 100000U / g lactase 0.3%, enzymatic hydrolysis for 1h;

[0045] (4) Protease hydrolysis: add 100,000U / g of neutral protease, when the amount of protease added is 0.02%-0.10%, the temperature is controlled at 30°C for 0.5 h;

[0046] (5) Homogenization: the pressure is controlled at 20MPa;

[0047] (6) Pre-sterilization: heat preservation at 95°C for 50 minutes to make the product have browning Maillard reaction;

[0048] (7) Concentration: The pressure is controlled at 0.09Mpa, the temperature is 50°C, and the three-effect concentration is carried out to a solid content of 65%.

[0049] (8) Homogene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com