QLED device

A technology of devices and quantum dot materials, applied in the field of QLED devices, can solve problems affecting the luminous purity and recombination efficiency of quantum dot light-emitting devices, affecting the luminous characteristics of quantum dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

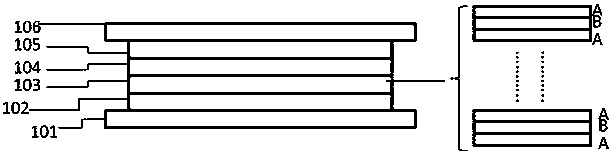

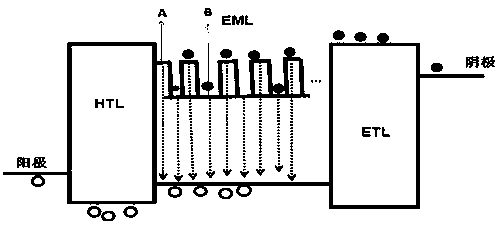

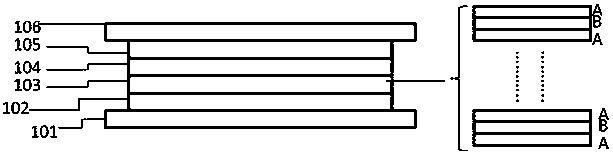

[0034] The structure of the QLED device in this embodiment is: an ITO anode layer, a PEDOT:PSS hole injection layer, a TFB hole transport layer, a [ZnSCdSZnS] light-emitting layer, a ZnO electron transport layer and an Al cathode layer are sequentially stacked on a glass substrate.

[0035] The preparation method of the QLED device in this embodiment is as follows:

[0036] a. Spin-coat one deck of PEDOT on ITO substrate:PSS thin film is used as hole injection layer;

[0037] b. Spin-coat a layer of TFB film on the PEDOT:PSS layer as a hole transport layer;

[0038] c. Deposit a quantum dot light-emitting layer based on a single-band difference superlattice structure by magnetron sputtering, wherein the quantum dot light-emitting layer is a three-layer single-band difference superlattice energy level structure functional layer, including sequentially arranged ZnSCdSZnS, with a thickness of 50nm, in which, the thickness of ZnS on both sides is 5nm, and the thickness of CdS in ...

Embodiment 2

[0042] The structure of the QLED device in this embodiment is: an ITO anode layer, a PEDOT:PSS hole injection layer, a TFB hole transport layer, a [ZnSCdSZnS]2 light-emitting layer, a ZnO electron transport layer and an Al cathode layer formed sequentially on a glass substrate .

[0043] The preparation method of the QLED device in this embodiment is as follows:

[0044] a. Spin-coat one deck of PEDOT on ITO substrate:PSS thin film is used as hole injection layer;

[0045] b. Spin-coat a layer of TFB film on the PEDOT:PSS layer as a hole transport layer;

[0046] c. Deposit a quantum dot light-emitting layer based on a single-band difference superlattice structure by magnetron sputtering, wherein the quantum dot light-emitting layer is a six-layer single-band difference superlattice energy level structure functional layer, including sequentially arranged [ZnSCdSZnS]2, the thickness is 40nm, in which, the thickness of ZnS on both sides is 5nm, and the thickness of CdS in the ...

Embodiment 3

[0050] The structure of the QLED device in this embodiment is: an ITO anode layer, a PEDOT:PSS hole injection layer, a TFB hole transport layer, a [ZnSCdSZnS]2 light-emitting layer, a ZnO electron transport layer and an Al cathode layer formed sequentially on a glass substrate .

[0051] The preparation method of the QLED device in this embodiment is as follows:

[0052] a. Spin-coat one deck of PEDOT on ITO substrate:PSS thin film is used as hole injection layer;

[0053] b. Spin-coat a layer of TFB film on the PEDOT:PSS layer as a hole transport layer;

[0054] c. Deposit a quantum dot light-emitting layer based on a single-band difference superlattice structure by magnetron sputtering, wherein the quantum dot light-emitting layer is a six-layer single-band difference superlattice energy level structure functional layer, including sequentially arranged [ZnSCdSZnS]2, the thickness is 36nm, in which, the thickness of ZnS on both sides is 4nm, and the thickness of CdS in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence spectrum | aaaaa | aaaaa |

| Luminescence spectrum | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com