A kind of double-layer inorganic insulation coated soft magnetic powder and its preparation method

A technology of inorganic insulating and soft magnetic powder, which is applied in the fields of inorganic material magnetism, permanent magnet manufacturing, inductor/transformer/magnet manufacturing, etc. problems, to achieve the effect of wide applicability, good chemical wettability, and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the other hand, the embodiment of the present application also provides a method for preparing a double-layer inorganic insulating coated soft magnetic powder, the method comprising the following steps:

[0031] S1. Carry out in-situ oxidation coating on the magnetic powder.

[0032] Put a certain amount of metal magnetic powder in the reactor, heat it to 100-500°C under the first inert fluidizing gas, and pass it into an oxidizing atmosphere for in-situ oxidation. The oxidation time is 1-60min, forming a coating on the outer surface of the magnetic powder transition oxide layer.

[0033] In the present application, the inlet velocity of the first inert fluidizing gas is 2-5 times of the fluidizing gas velocity (that is, the lowest gas velocity that can make the materials in the reactor fluidized).

[0034] Preferably, before the in-situ oxidation of the magnetic powder, the metal magnetic powder can also be reduced first, that is, before the oxidation atmosphere is...

Embodiment 1

[0057] This embodiment provides a double-layer inorganic insulating coated soft magnetic powder (Fe-6.5Si / FeOx / alumina) and a preparation method thereof.

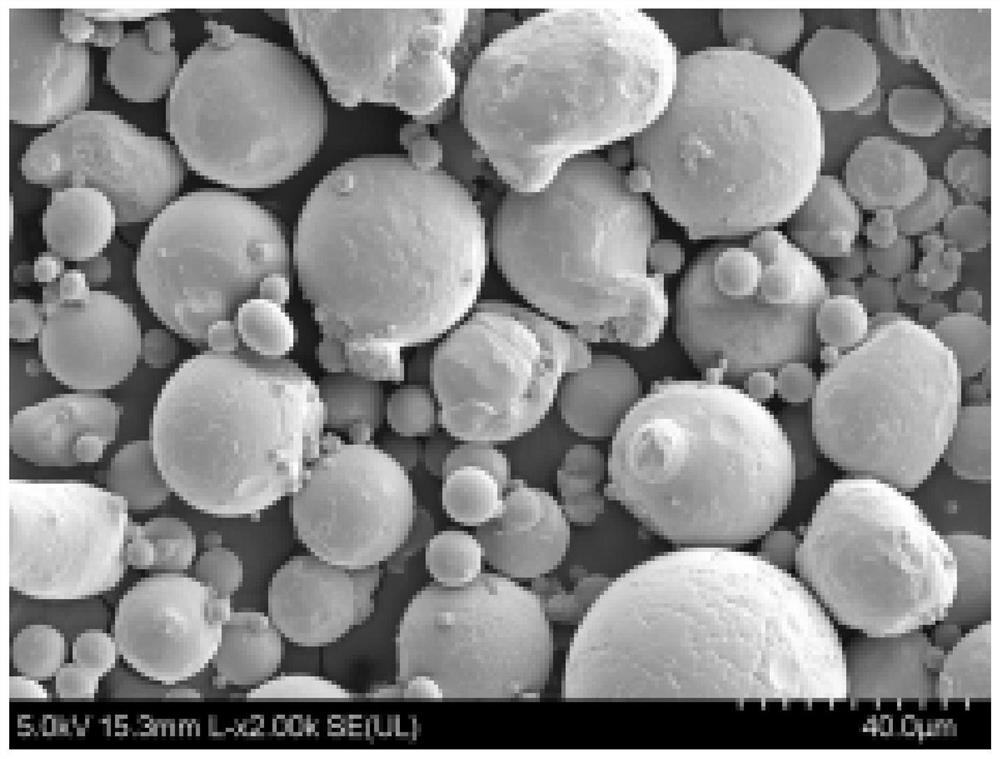

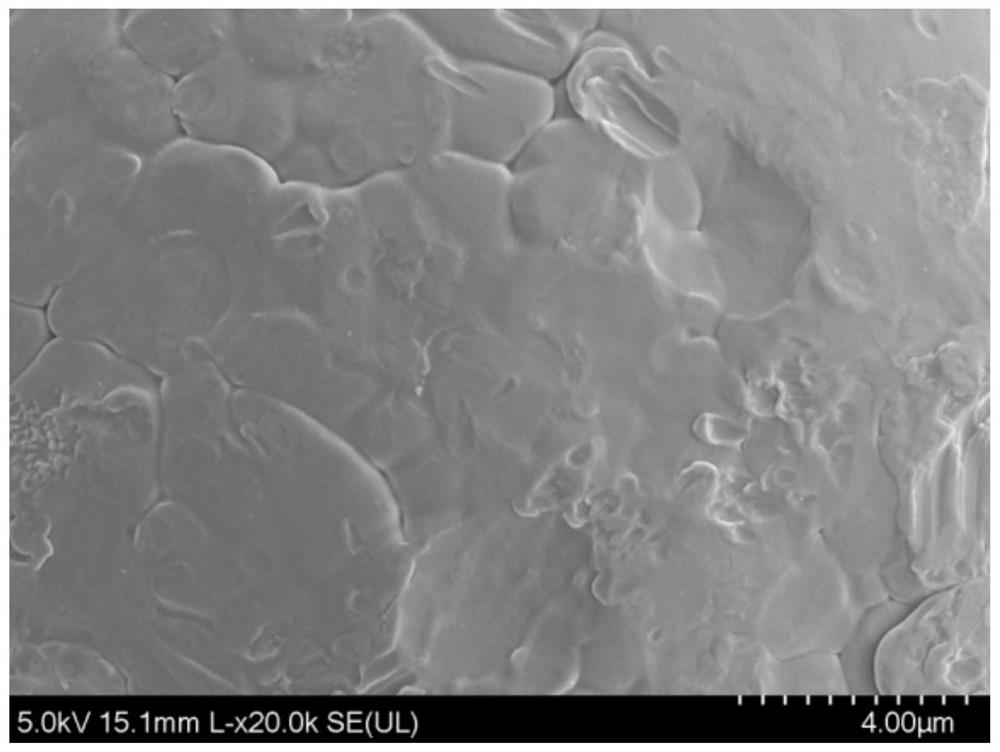

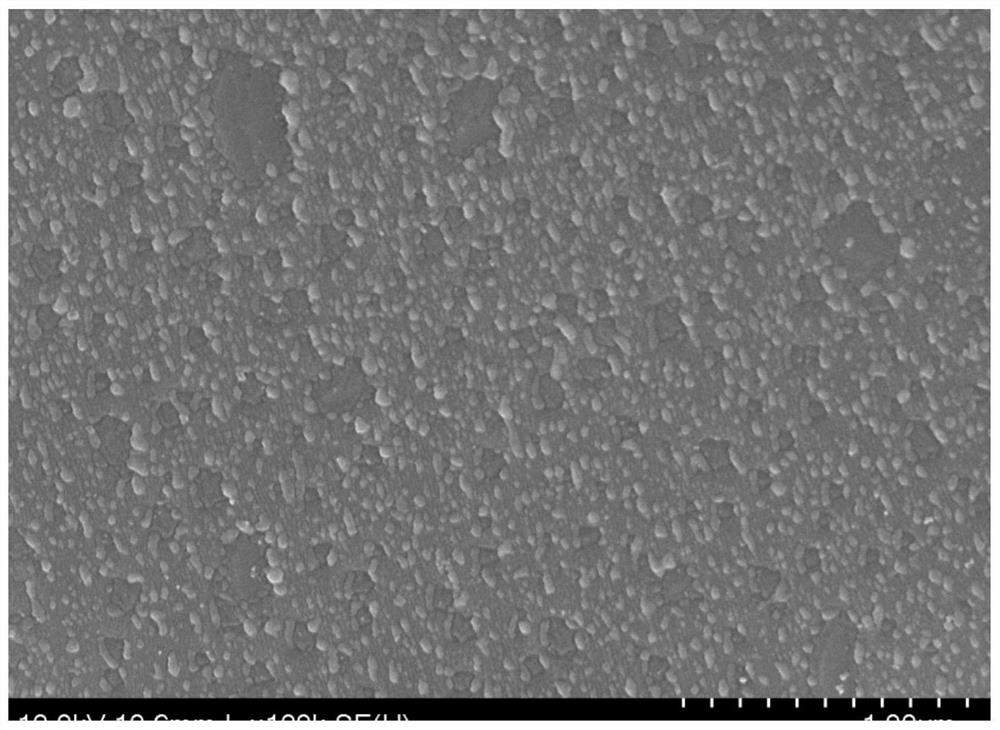

[0058] 40g, 150-mesh Fe-6.5Si magnetic powder was stirred and cleaned with ethanol and acetone, respectively, for 15 minutes each time, and then dried at 70°C for 2 hours. Such as figure 1 with figure 2 As shown, Fe-6.5Si is spherical or nearly spherical, with a smooth surface. Put the cleaned Fe-6.5Si magnetic powder in the fluidized bed reactor, the first inert fluidizing gas N at 3 times the fluidizing gas velocity 2 Heating to 300°C under protection, in reducing atmosphere N 2 -H 2 (1:1) reduction for 15min, then feed pure N into the reactor for 10min 2 to drive away the reducing atmosphere, and then in the oxidizing atmosphere N 2 / O 2 (4:1) in-situ oxidation for 20 minutes to form a transition oxide layer with a thickness of 45 nm. Such as image 3 As shown, the surface of the powder becomes rough after in-s...

Embodiment 2

[0060] This embodiment provides a double-layer inorganic insulating coated soft magnetic powder (Fe / FeOx / silicon oxide) and a preparation method thereof.

[0061] 40g, 150mesh Fe magnetic powder was stirred and washed once with water and acetone respectively, each time for 15min, and then dried at 55°C for 3h. Fe is spherical or nearly spherical, with a smooth surface. Put the cleaned Fe magnetic powder in a fluidized bed reactor, and heat it to 200°C under the protection of the first inert fluidizing gas Ar gas of 2 times the fluidizing gas velocity, and in the reducing atmosphere Ar gas-H 2 (1:2) reduction for 15min, then into the reactor for 10min pure Ar gas to drive away the reducing atmosphere, and then in the oxidizing atmosphere Ar gas / O 2 (1:2) in-situ oxidation for 30 minutes to form a transition oxide layer with a thickness of 20 nm. After in-situ oxidation, the surface of the powder becomes rough, and a large number of nanoscale protrusions are formed. Then, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com