A continuous winding stacked paper square tube forming device

A tube forming and stacking technology, applied in the direction of cardboard winding articles, etc., to achieve high dimensional accuracy, reduce manufacturing costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

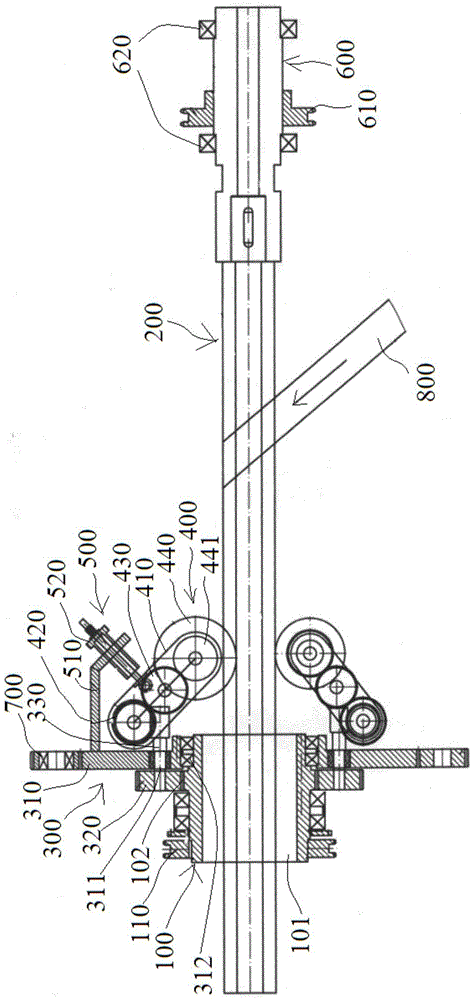

[0028] See figure 1 The shown continuous winding laminated paper square tube forming device includes a hollow shaft 100, a square tube mandrel mold 200, a four-planet rotating mechanism 300, a paper pressing roller mechanism 400 and an adjusting device 500. The hollow shaft 100 is arranged on a frame (not shown in the figure), and a jog drive sprocket 110 is arranged on the outer periphery of the rear end of the hollow shaft 100. In this embodiment, the hollow shaft 100 is further provided with teeth 102 on the outer periphery of the middle portion.

[0029] The tail end of the square tube core rod mold 200 penetrates the inner cavity 101 of the hollow shaft 100. In order to facilitate the replacement of different types of square tube mandrel mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com