Worktable base used for manufacturing of energy-saving lamps

A technology of work and pedestal, applied in cleaning methods and utensils, cleaning hollow objects, material gluing, etc., can solve problems such as low efficiency and poor precision, and achieve the effects of improving quality, reducing lamp damage, and inhibiting displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

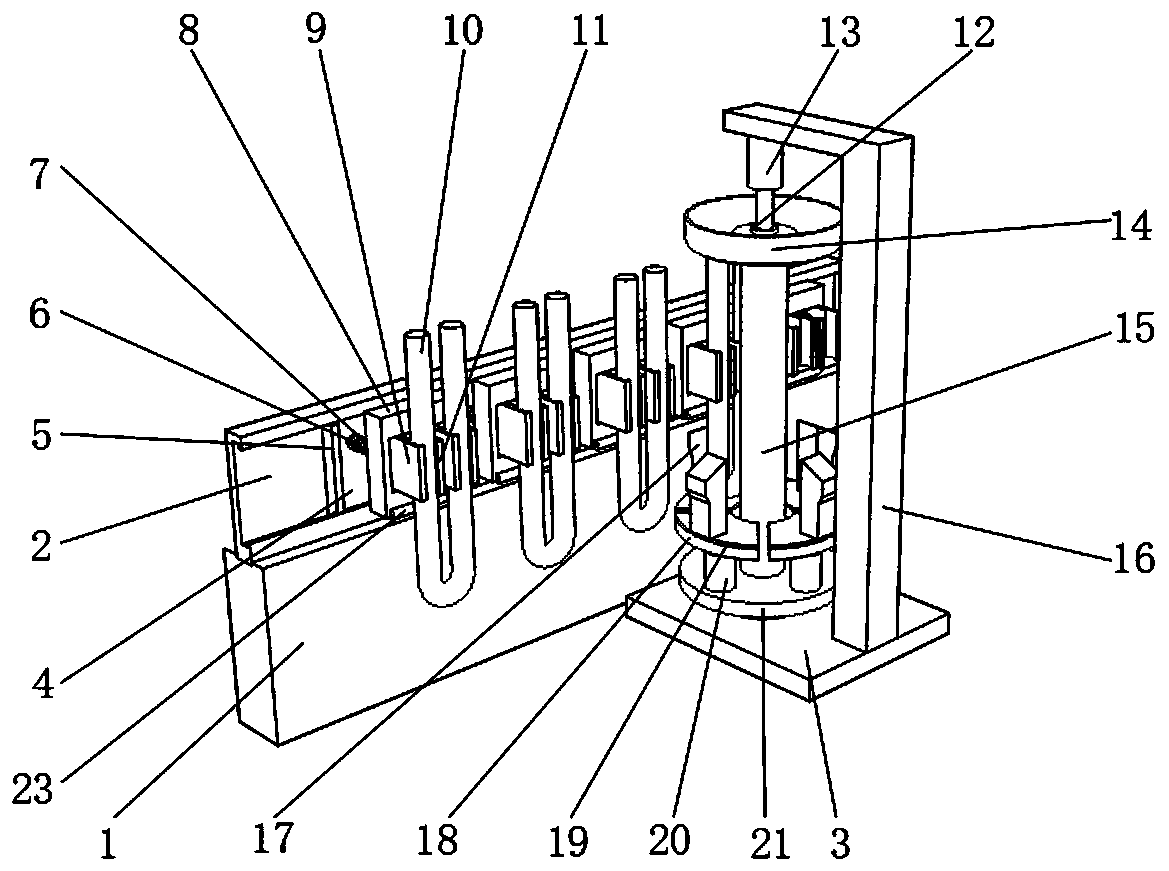

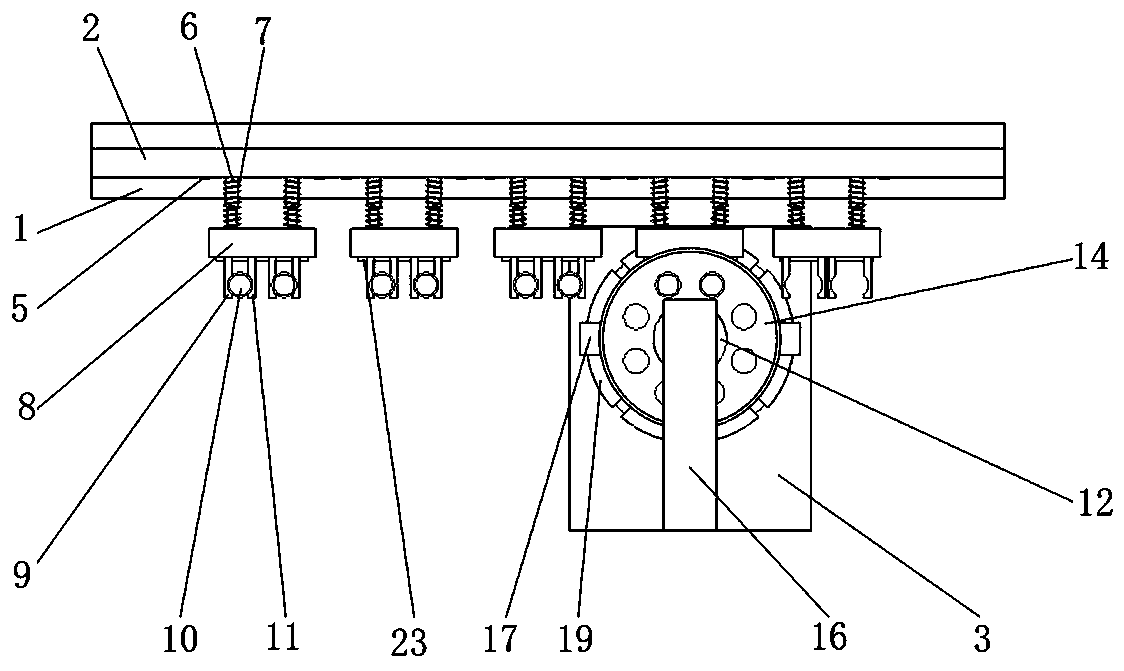

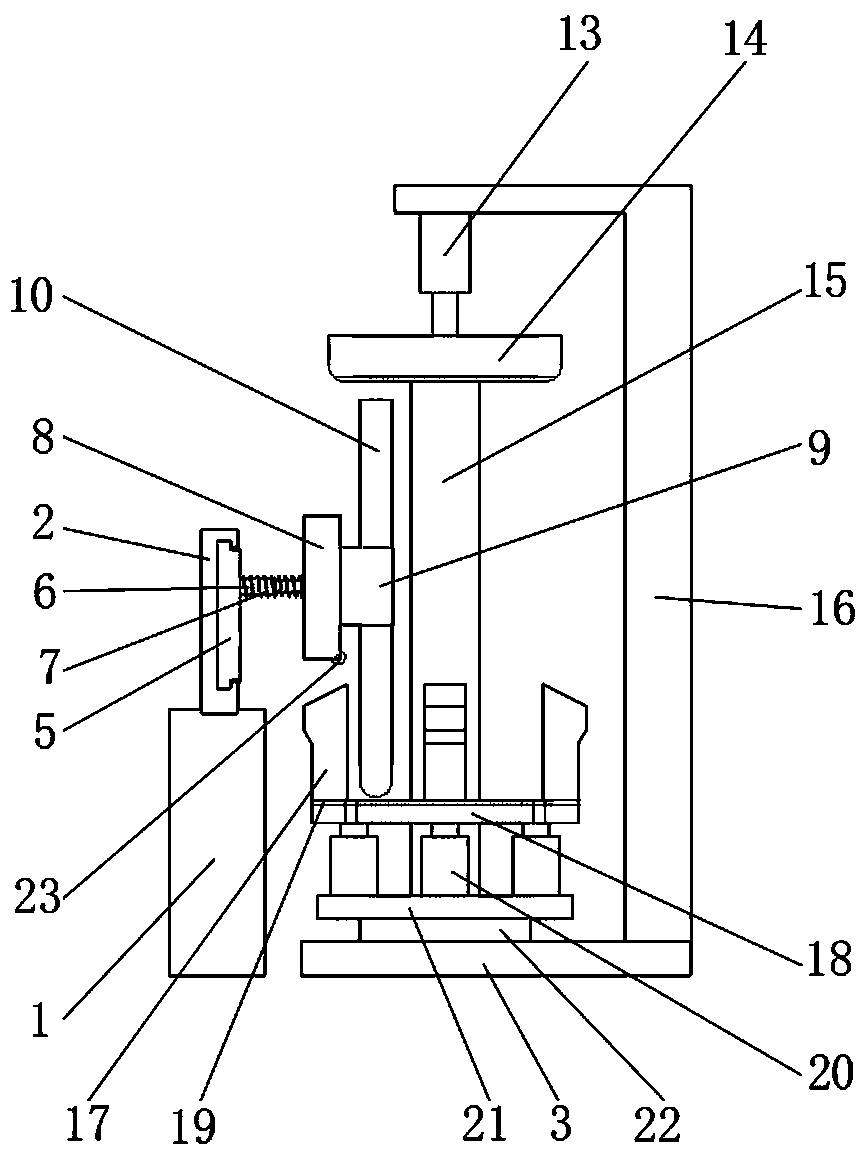

[0022] refer to Figure 1-4 , a workbench for the manufacture of energy-saving lamps, including a fixed seat 1 and a base 3, the top of the fixed seat 1 is slidably connected to a conveying frame 2, and a groove is opened on one side of the conveying frame 2, and a fixing plate 4 and a fixed plate 4 are slidably connected in the groove Limiting plate 5, the height of fixed plate 4 is consistent with the height of groove, and one side of fixed plate 4 is welded with movable rod 6, and movable rod 6 is sleeved with spring 7, and one end of movable rod 6 is welded with mounting plate 8, and The stroke of the movable rod 6 is greater than the distance between the fixed plate 4 and the fixed seat 1, the fixed plate 4 moves in the groove of the conveyor frame, and the lamp conveyor belt is assigned a position, and the top of the base 3 is welded with a rotating shaft 22 and a mounting frame 16, and One side of the installation frame 16 is welded with a telescopic rod 13, the bottom ...

Embodiment 2

[0025] Embodiment 2 refers to Figure 5-6, a workbench for the manufacture of energy-saving lamps, which also includes a control box 25, the control box 25 is welded on the top of the installation frame 16, and an air pump 26 is connected to one side of the control box 25 through bolts, and the air pump 26 generates air for the air blowing pipe 27, and recovers The air inhaled by the suction pipe 28 is welded with two casings at the bottom of the control box 25, and the two casings are respectively sleeved with a blowing pipe 27 and a suction pipe 28, and the blowing pipe 27 and the suction pipe 28 go deep into the top of the lamp tube 10 respectively. opening.

[0026] Working principle of this embodiment: when in use, the support plate 18 lifts the lamp tube 10 through the lifter 20, and when the lamp tube 10 passes through the hole of the lamp holder 14, the control box 25 controls the blowing pipe 27 and the suction pipe 28 to extend. into the lamp tube 10, the air pump 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com