Touch electrode structure, touch substrate and manufacturing method, display panel and device

A technology of touch electrodes and conductive structures, applied in circuits, electrical components, electric solid devices, etc., can solve problems such as uneven touch electrode signals, achieve improved touch effects, low resistance, and strong signal transmission capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

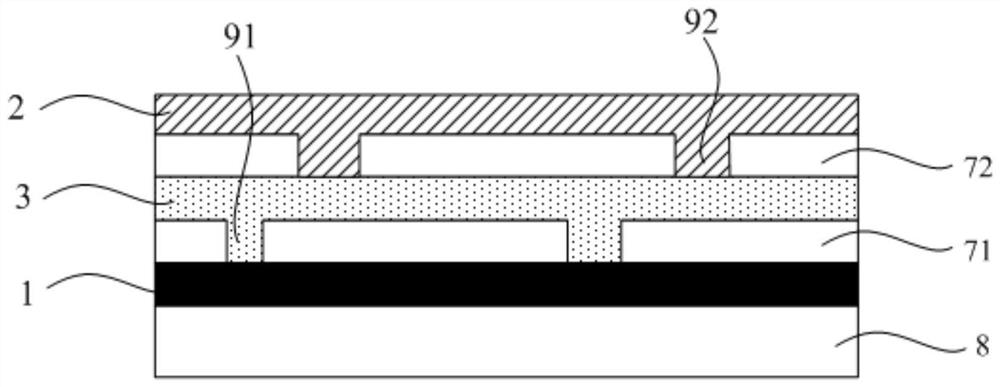

[0057] This embodiment provides a touch electrode structure, which includes:

[0058] Touch electrodes made of transparent conductive materials;

[0059] A signal line corresponding to the touch electrode, at least one insulating layer is provided between the signal line and the touch electrode;

[0060] An auxiliary conductive structure made of metal, the auxiliary conductive structure is connected to the touch electrode at multiple positions; and a first insulating layer is provided between the auxiliary conductive structure and the signal line, and the first via hole in the first insulating layer is connected to the touch The signal line corresponding to the control electrode is connected.

[0061] In the touch electrode structure of this embodiment, the signal line is indirectly electrically connected to the touch electrode through the auxiliary conductive structure, and the auxiliary conductive structure is made of metal, which has low resistance and strong signal transm...

Embodiment 2

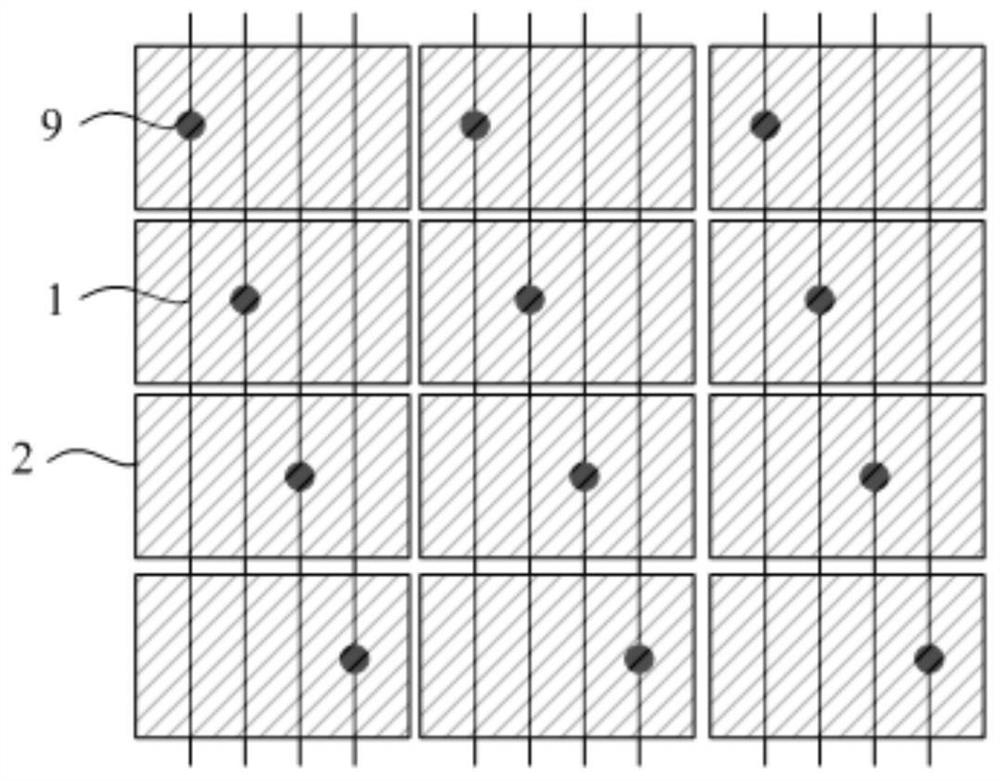

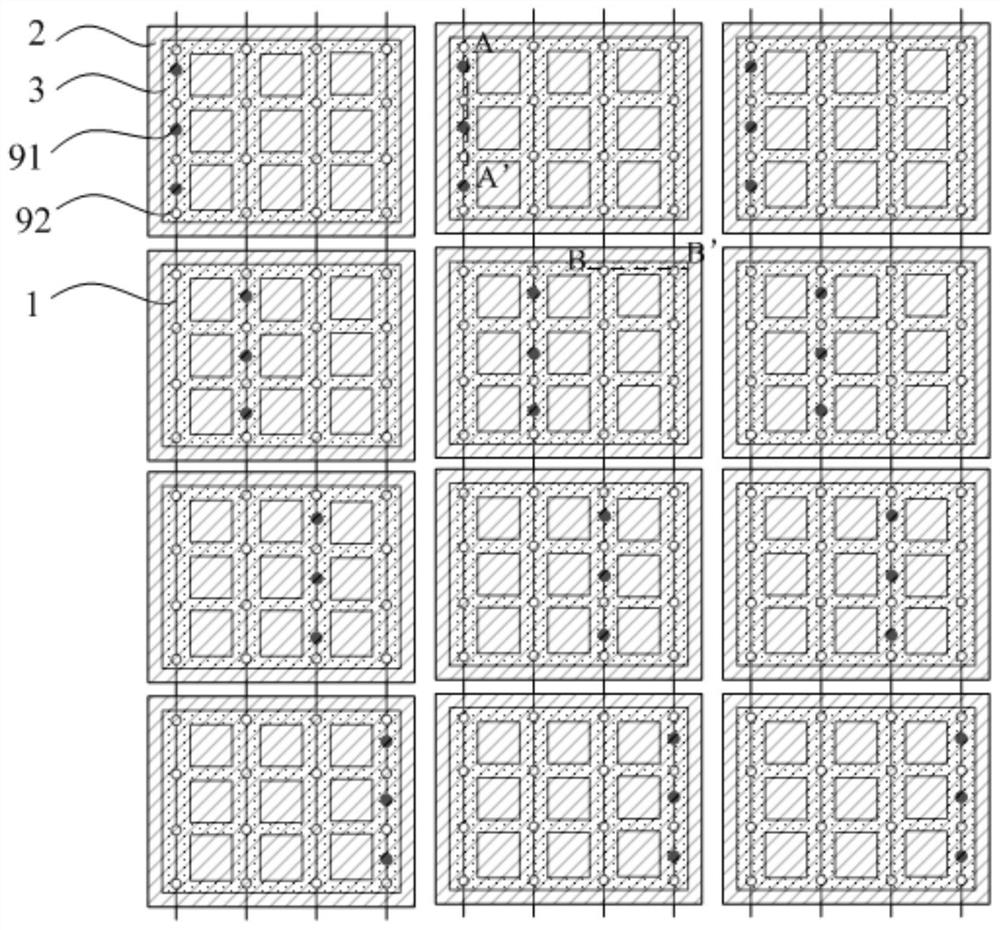

[0072] Such as Figure 2 to Figure 5 As shown, the present embodiment provides a touch control substrate, which includes the above touch control electrode structure. Specifically, the touch substrate includes:

[0073] A plurality of touch electrodes 2 arranged at intervals and made of transparent conductive materials;

[0074] A plurality of signal lines 1 correspond one-to-one to the touch electrodes 2 , and at least one insulating layer (such as a first insulating layer 71 , a second insulating layer 72 , etc.) is disposed between the signal lines 1 and the touch electrodes 2 .

[0075] The touch substrate of this embodiment is used to realize the touch function, that is, to identify the touched position. In the touch substrate, a plurality of touch electrodes 2 made of transparent conductive materials such as indium tin oxide (ITO) are arranged at intervals, and each touch electrode 2 corresponds to a signal line 1 . Thus, a touch signal (such as a high-frequency signal...

Embodiment 3

[0105] This embodiment provides a method for preparing the above-mentioned touch substrate, which includes:

[0106] A step of forming a touch electrode, a step of forming a signal line, a step of forming a first insulating layer, and a step of forming an auxiliary conductive structure.

[0107] That is to say, the manufacturing method of the touch control substrate in this embodiment includes the steps of forming each structure in the above touch control substrate.

[0108] It should be understood that when the touch control substrate includes other structures such as gate lines and data lines, the preparation method also includes the step of forming these structures, and these structures can be formed separately or synchronously with the above touch control structures. of.

[0109] Wherein, the formation of the above structures can be realized by conventional techniques such as patterning technology; and the order of forming each structure is determined by the stacking orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com