Preparation method of special nanometer calcium carbonate for antifogging polyethylene films

A nano-calcium carbonate, anti-fog film technology, applied in chemical instruments and methods, fibrous fillers, dyed low molecular organic compound treatment and other directions, to achieve the effects of low production cost, easy infiltration and spreading, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

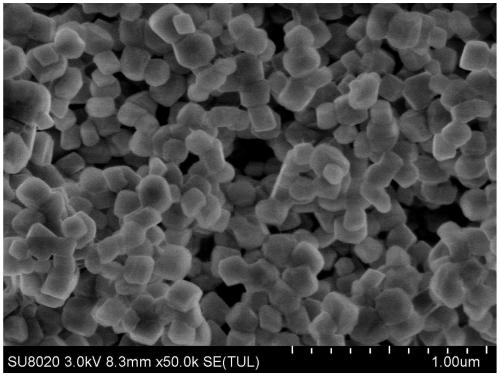

Image

Examples

Embodiment 1

[0027] A kind of preparation of nano-calcium carbonate special for polyethylene anti-fog film, comprising the following steps:

[0028] (1) Dilute the milk of lime that has been refined and aged for 24 hours, adjust the specific gravity to 1.050, and then transport it to the membrane reaction carbonizer with an initial temperature of 22°C;

[0029] (2) Pass the purified and cooled kiln gas into the membrane reactor for carbonation reaction, the kiln gas flow rate is 25m 3 / h, the volume content of carbon dioxide is 32%, and when the pH of the reaction solution drops to 7.0, the reaction is terminated, and the nano calcium carbonate slurry is obtained, and its specific surface area is 17.8m 2 / g;

[0030] (3) After step (2) is completed, add 1.2% sodium carboxymethylcellulose into the membrane reactor, stir evenly, and transport to the homogenization tank for insulation aging for 16 hours;

[0031] (4) The calcium carbonate slurry after step (3) aging is transported to the su...

Embodiment 2

[0035] A kind of preparation of nano-calcium carbonate special for polyethylene anti-fog film, comprising the following steps:

[0036] (1) Dilute the milk of lime that has been refined and aged for 24 hours, adjust the specific gravity to 1.040, and then transport it to the membrane reaction carbonizer with an initial temperature of 23°C;

[0037] (2) Pass the purified and cooled kiln gas into the membrane reactor for carbonation reaction, the kiln gas flow rate is 25m 3 / h, the volume content of carbon dioxide is 33%, and when the pH of the reaction solution drops to 7.0, the reaction is terminated, and the nano calcium carbonate slurry is obtained, and its specific surface area is 19.4m 2 / g;

[0038] (3) After step (2) is completed, add 1.6% sodium carboxymethyl cellulose into the membrane reactor, stir evenly and transport to the homogenization tank for insulation aging for 16 hours;

[0039] (4) Transport the aged calcium carbonate slurry in step (3) to a surface treat...

Embodiment 3

[0042] (1) Dilute the milk of lime that has been refined and aged for 24 hours, adjust the specific gravity to 1.055, and then transport it to the membrane reaction carbonizer with an initial temperature of 20°C;

[0043] (2) Pass the purified and cooled kiln gas into the membrane reactor for carbonation reaction, the kiln gas flow rate is 30m 3 / h, the volume content of carbon dioxide is 30%, and when the pH of the reaction solution drops to 7.0, the reaction is terminated, and the nano calcium carbonate slurry is obtained, and its specific surface area is 15.7m 2 / g;

[0044] (3) After step (2) is completed, add 0.8% sodium carboxymethyl cellulose into the membrane reactor, stir evenly and transport to the homogenization tank for heat preservation and aging for 16 hours;

[0045] (4) The calcium carbonate slurry after step (3) aging is transported to the surface treatment tank, is heated to 70 ℃, adds 3.0% glyceryl laurate, glyceryl myristate and polyphenyltrimethoxysiloxane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com