Strong-toughness and anti-fouling dual-network hydrogel and preparation method thereof

A dual-network, hydrogel technology, applied in the field of polymer hydrogels, can solve the problems of lack of biocompatibility, anti-protein non-specific adsorption performance, etc., achieve good biocompatibility, and be conducive to large-scale industrial production , the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

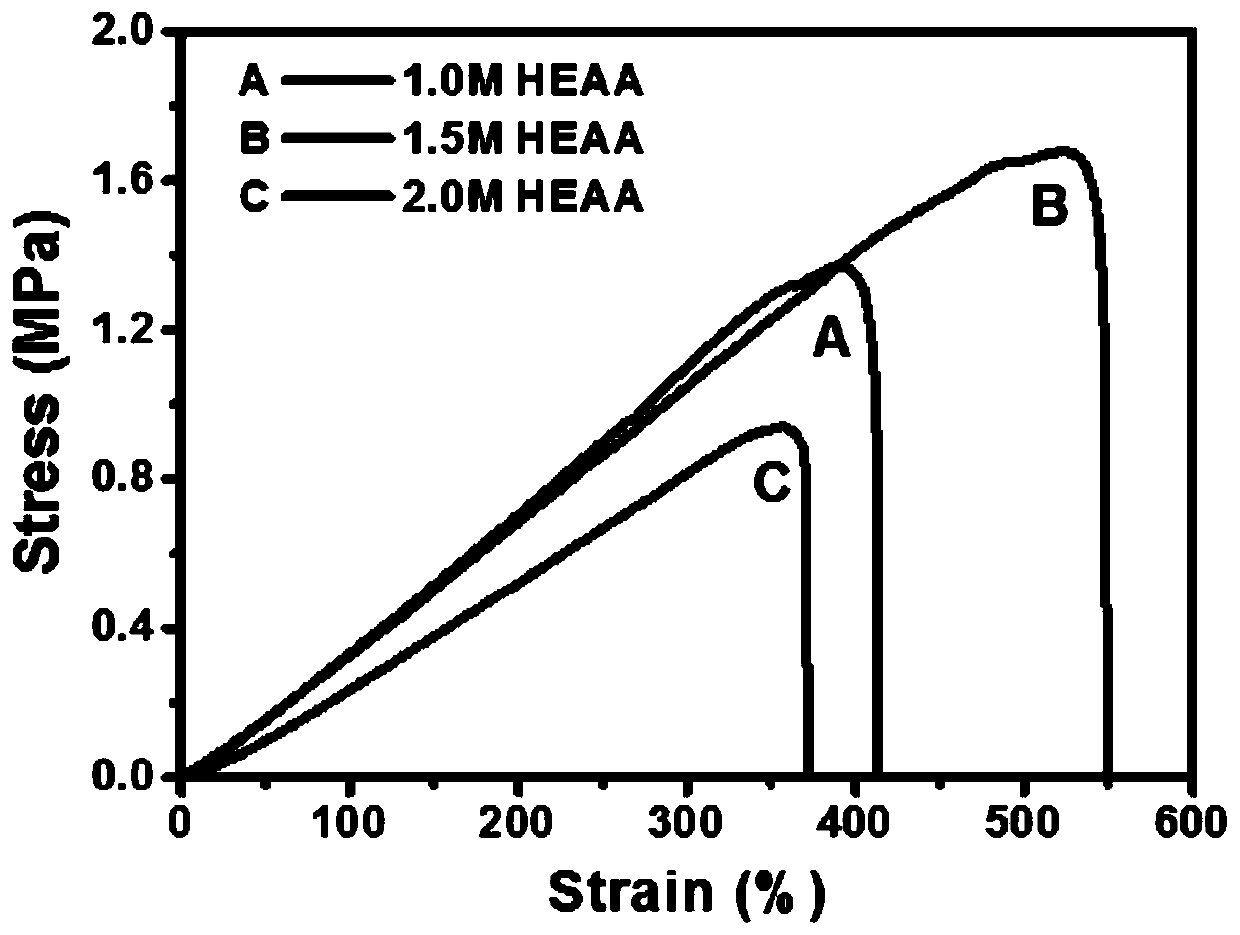

Embodiment 1

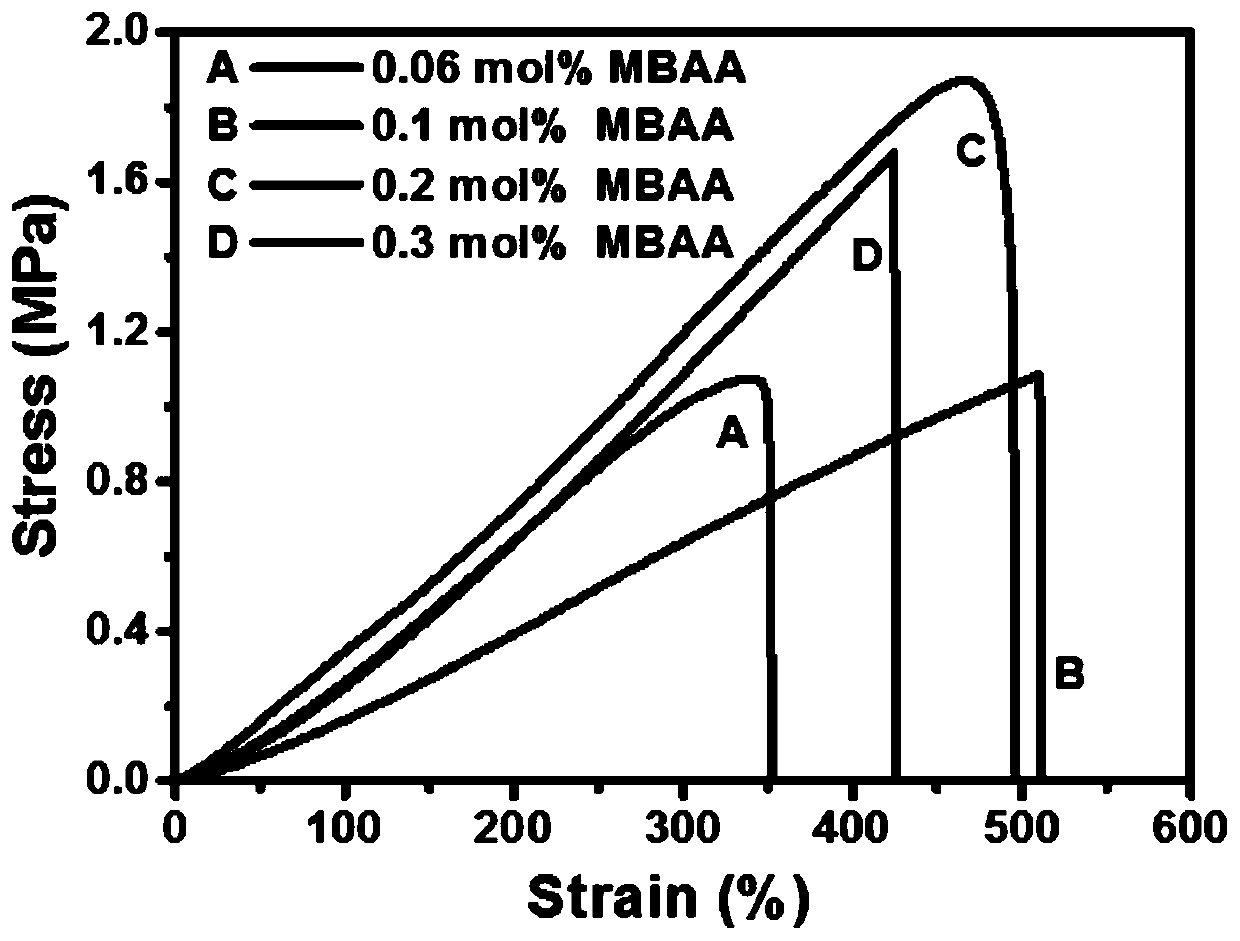

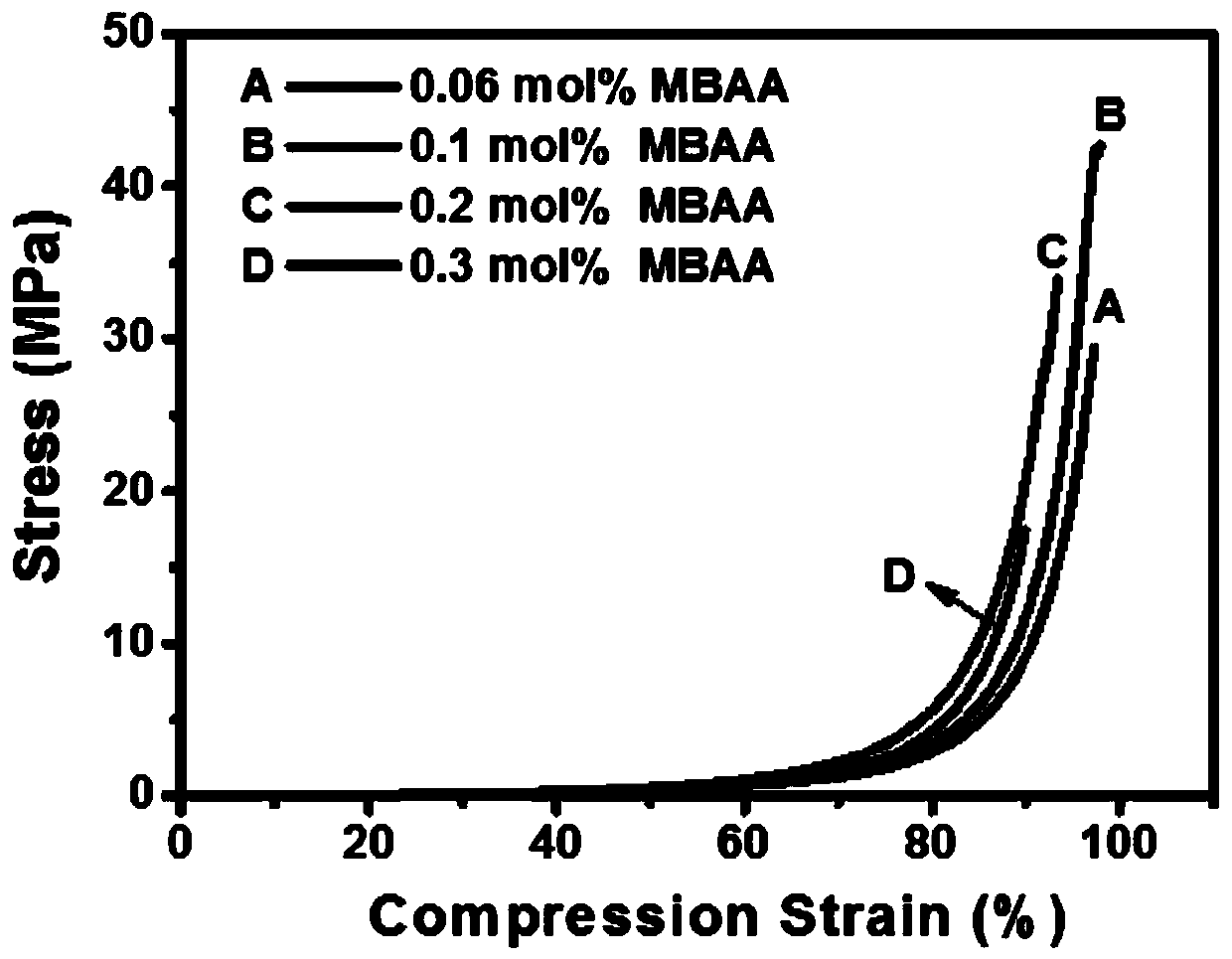

[0039] (1) Add 0.71g (1.0M) of N-hydroxyethylacrylamide (HEAA) and 0.36g of sodium alginate (SA) with a molecular viscosity of 180mPa.s (1%, 2°C) into 6mL of deionized water, Add 0.2 mol% (relative to HEAA) N,N-methylenebisacrylamide (MBAA) and 1 mol% (relative to HEAA) ammonium persulfate, and stir for 20 minutes to obtain a uniform mixed solution;

[0040] (2) Nitrogen gas was passed into the above mixed solution for 10 minutes, sonicated for 30 minutes under the condition of 80W ultrasonic power, and centrifuged at 7500rpm for 5 minutes;

[0041] (3) Inject the mixed solution treated in step (2) into a sealed glass mould, react at 50°C for 6h under a nitrogen atmosphere, and obtain a covalently crosslinked network after the reaction; during the reaction, the N- Hydroxyethylacrylamide forms a covalent crosslinked network through chemical crosslinking, and free sodium alginate molecules are uniformly embedded in the covalent crosslinked network;

[0042] (4) Put the covalent...

Embodiment 2

[0045] (1) Add 1.07g (1.5M) of N-hydroxyethylacrylamide (HEAA) and 0.36g of sodium alginate (SA) with a molecular viscosity of 220mPa.s (1%, 2°C) into 6mL of deionized water, Add 0.2 mol% (relative to HEAA) N,N-methylenebisacrylamide (MBAA) and 1 mol% (relative to HEAA) ammonium persulfate, and stir for 20 minutes to obtain a uniform mixed solution;

[0046] (2) Nitrogen gas was passed into the above mixed solution for 10 minutes, sonicated for 50 minutes under the condition of 300W ultrasonic power, and centrifuged at 7500rpm for 5 minutes;

[0047] (3) Inject the mixed solution treated in step (2) into a sealed glass mould, react at 50°C for 6h under a nitrogen atmosphere, and obtain a covalently crosslinked network after the reaction; during the reaction, the N- Hydroxyethylacrylamide forms a covalent crosslinked network through chemical crosslinking, and free sodium alginate molecules are uniformly embedded in the covalent crosslinked network;

[0048] (4) Put the covalen...

Embodiment 3

[0051] (1) Add 1.43g (2.0M) N-hydroxyethylacrylamide (HEAA) and 0.36g sodium alginate (SA) with a molecular viscosity of 200mPa.s (1%, 2°C) into 6mL deionized water, Add 0.2 mol% (relative to HEAA) N,N-methylenebisacrylamide (MBAA) and 1 mol% (relative to HEAA) ammonium persulfate, and stir for 20 minutes to obtain a uniform mixed solution;

[0052] (2) Introduce nitrogen gas into the above mixed solution for 30 minutes, sonicate for 40 minutes under the condition of 300 W ultrasonic power, and centrifuge at 7000 rpm for 8 minutes;

[0053] (3) Inject the mixed solution treated in step (2) into a sealed glass mold, react at 45°C for 6h under nitrogen atmosphere, and obtain a covalently crosslinked network after the reaction; during the reaction, the N- Hydroxyethylacrylamide forms a covalent crosslinked network through chemical crosslinking, and free sodium alginate molecules are uniformly embedded in the covalent crosslinked network;

[0054] (4) Put the covalent cross-linke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com