Biological denitrification coupled N2O recovery integrated reactor and method thereof

A biological denitrification and reactor technology, which is applied in chemical instruments and methods, biological water/sewage treatment, biological treatment devices, etc., to achieve the effect of reducing floor space, improving treatment efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

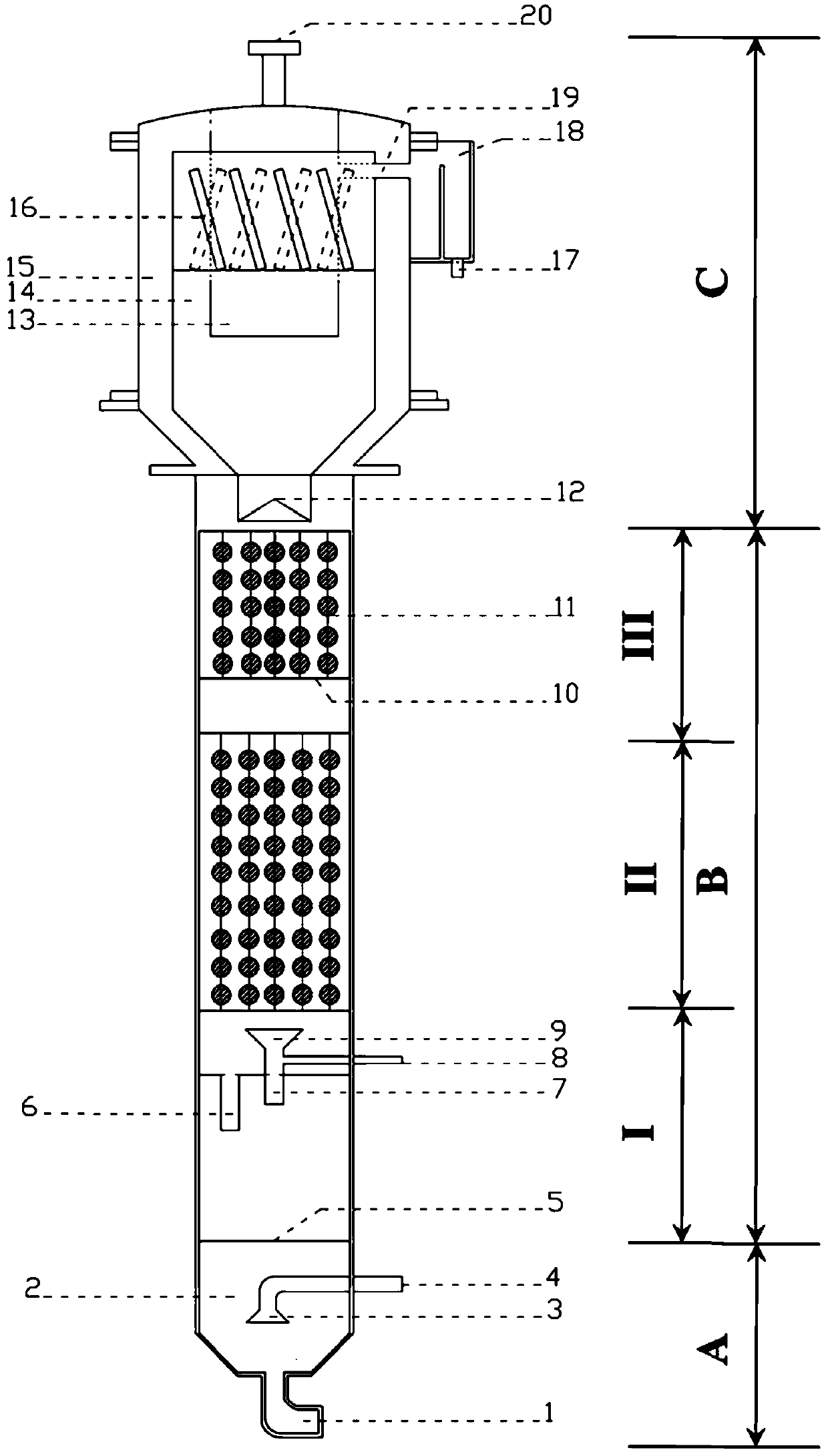

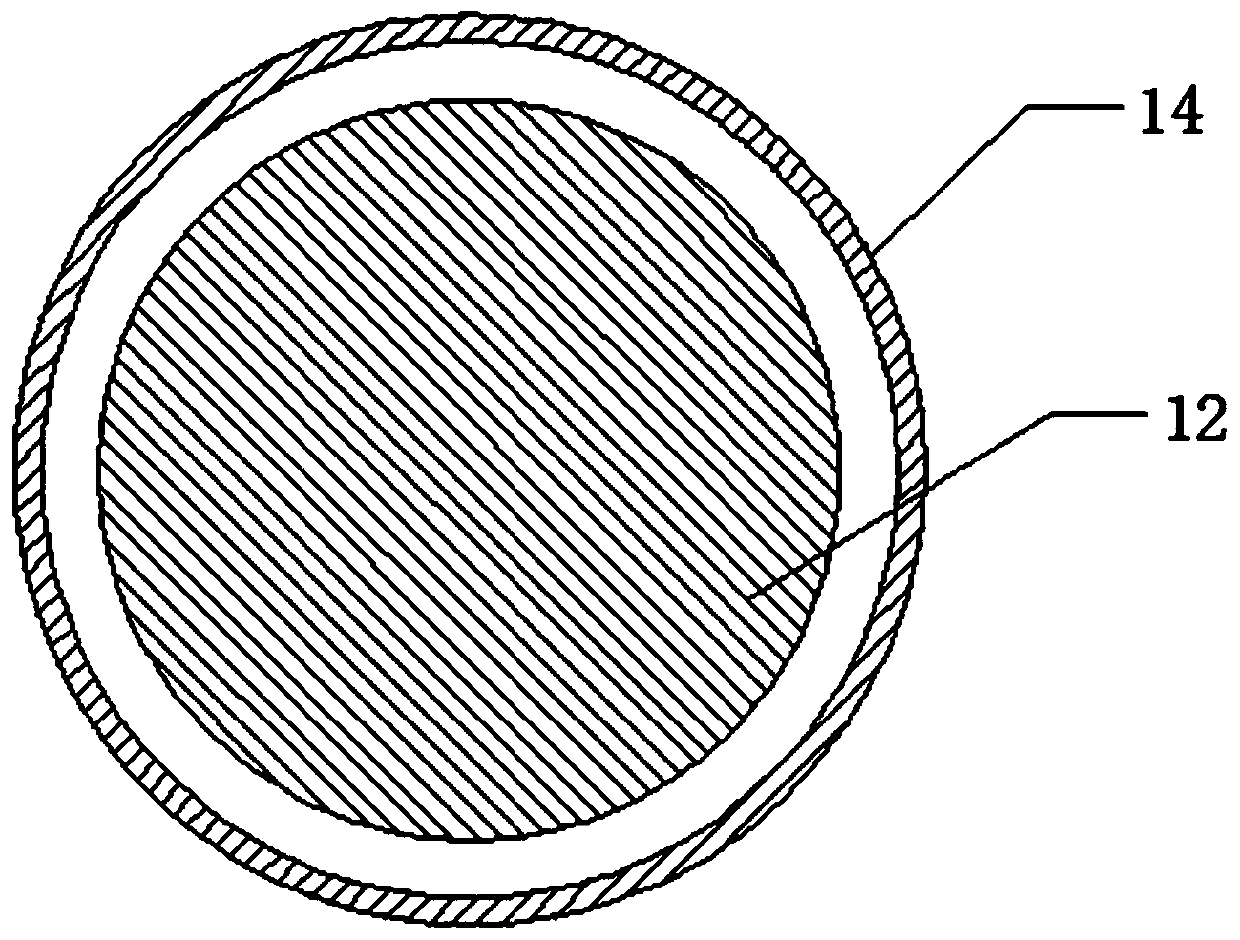

[0030] like figure 1 As shown, it is a kind of biological denitrification coupling N given in a preferred embodiment of the present invention 2 O recovery integrated reactor, biological nitrogen removal coupled with N 2O recovery integrated reactor can be made of PVC transparent sheet. The reactor body is sequentially divided into a water distribution area A, a reaction area B and a three-phase separation area C from bottom to top. Its specific structure includes mud discharge pipe 1, water flow mixing distribution chamber 2, water inlet distributor 3, water inlet pipe 4, transverse partition net 5, return pipe 6, exhaust pipe 7, air inlet pipe 8, aeration head 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com