Nano channel type natural controlled-release carrier material and preparation method thereof

A technology of nano-pores and carrier materials, applied in the fields of botanical equipment and methods, chemicals for biological control, pharmaceutical formulations, etc., can solve the problems of industry development restrictions, waste water pollution, high production costs, and avoid decomposition or loss. , to ensure the safety of medication, to ensure long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

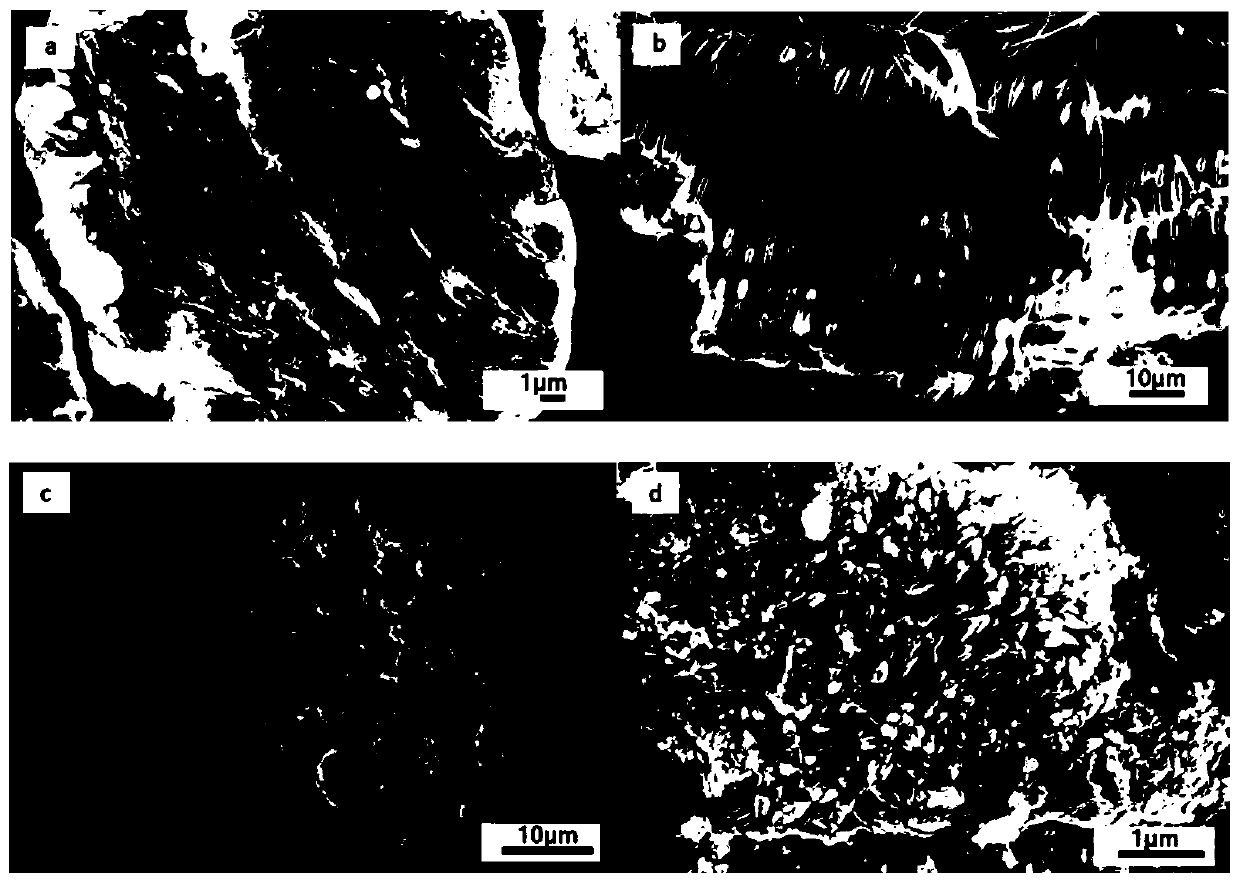

[0094] Example 1 Preparation of chitin-protein composite bio-based material with shrimp shells

[0095] First rinse the shrimp shells and dry them at 160°C, take them out and add them to a single-necked flask equipped with an electric stirrer, and prepare a citric acid solution with a concentration of 10%, wherein the mass ratio of the shrimp shells to the citric acid solution is 1:10, Heating to 50°C, heat preservation treatment for 4 hours to decalcify, select warm water at 50°C to filter through a mesh sieve, recover the calcium citrate in the filtrate, and perform secondary decalcification on the obtained filtrate according to the same experimental conditions, and finally use Filter through a mesh sieve, rinse the filtrate with an appropriate amount of distilled water for several times until it becomes neutral, and after drying, grind it to 200 mesh with a pulverizer to obtain the chitin-protein composite bio-based material. Dry again to constant weight and set aside. Ref...

Embodiment 2

[0096] Embodiment 2 prepares chitosan-calcium carbonate composite bio-based material with shrimp shell

[0097] Add 150.0g of shrimp shell powder to a three-necked flask equipped with an electric stirrer, mix and dissolve 80.0g of potassium hydroxide solid with 40.0g of water, add 400mL of isopropanol, stir evenly, pour into a three-necked flask, React at low temperature for 3.0h, fully hydrolyze the protein and remove acetyl groups, filter, stir the obtained solid with 200mL isopropanol at room temperature for 0.5h, filter, wash with water three times, and dry to constant weight to obtain chitosan - Calcium carbonate composite bio-based material. The protein hydrolyzate obtained by filtration contains amino acids, small peptides and potassium hydroxide. After recycling the isopropanol solvent, it can be used as a raw material for liquid amino acids and potassium fertilizers. Measure the degree of deacetylation by acid-base titration or infrared spectroscopy, dissolve chitosa...

Embodiment 3

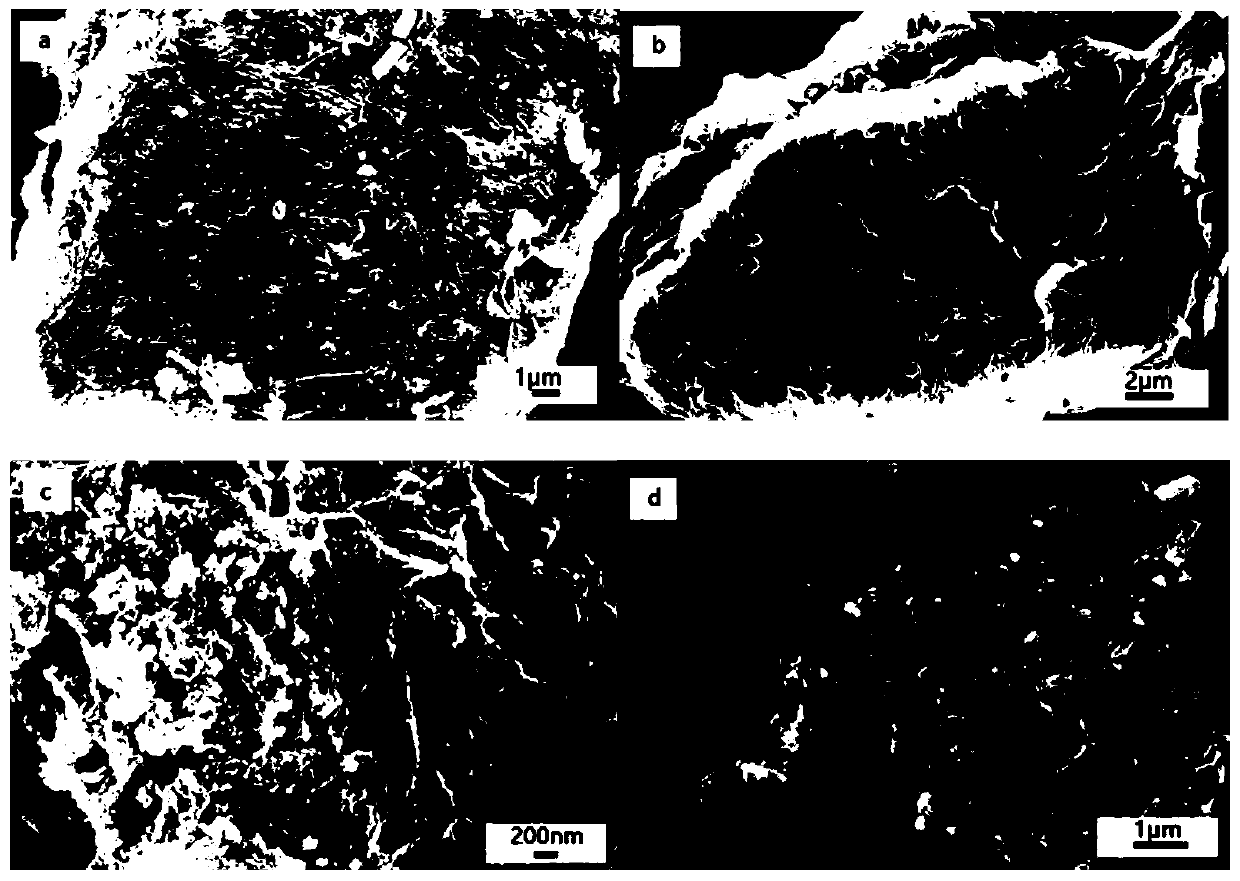

[0098] Embodiment 3 prepares calcium carbonate crude product with shrimp shell

[0099] Add 150.0g of shrimp shell powder to a three-necked flask equipped with an electric stirrer, mix and dissolve 80.0g of potassium hydroxide solid with 40.0g of water, add 400mL of isopropanol, stir evenly, pour into a three-necked flask, and reflux React for 3.0 hours, fully hydrolyze the protein and remove the acetyl group, then add 25.0g of chloroacetic acid, add in 5 times, react for 3.0 hours under the condition of 60 ℃ heat preservation, carry out carboxymethylation on chitosan, filter and separate to obtain carboxymethyl A mixture of chitosan and calcium carbonate, the mixture is dissolved in water, filtered to obtain the by-product porous calcium carbonate. The filtrate can be added with 80% ethanol to reverse precipitate the carboxymethyl chitosan product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com