Flame detection cooling air system used for preventing coking of coal-fired boiler and work method thereof

A coal-fired boiler and cooling air technology, which is applied in the direction of combustion methods, combustion chambers, and combustion equipment, can solve the problems of high ambient temperature, increased total flow of cooling and sweeping air, and poor cooling effect, so as to reduce the cooling air volume, Energy saving, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

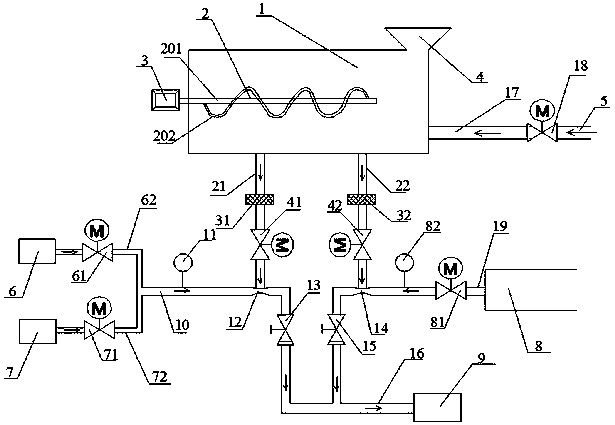

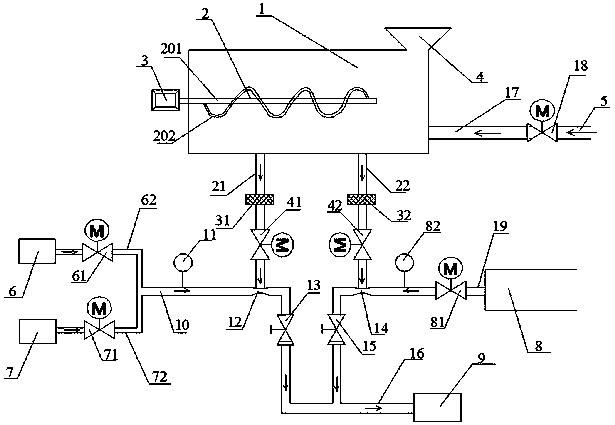

[0025] see figure 1 , the flame detection cooling air system used to prevent coal-fired boilers from coking in this embodiment, the A flame detection fan 6 and the B fire detection fan 7 are connected to the flame detection cooling air mother through the A cooling air duct 62 and the B cooling air duct 72 respectively. The pipes 10 are connected, and the flame detector cooling air main pipe 10 is connected to the flame detector 9 through the main pipe 16, wherein the A cooling air pipe 62 is provided with an A cooling air regulating valve 61, and the B cooling air pipe 72 is provided with a B cooling air pipe. The regulating valve 71, the first pressure gauge 11 and the first check valve 13 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com