Flow dividing opposite impact microreaction passage and microreactor

A technology of micro-reaction channel and shunt channel, applied in chemical/physical/physical chemical reactor, chemical/physical/physical chemical fixed reactor, detailed information of chemical/physical/physical chemical reactor, etc., can solve reaction The product yield is not high, the reaction cannot be fully mixed, and the mixing effect is general, etc., to reduce the possibility of safety accidents and quality accidents, improve safety and reliability, and ensure the effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

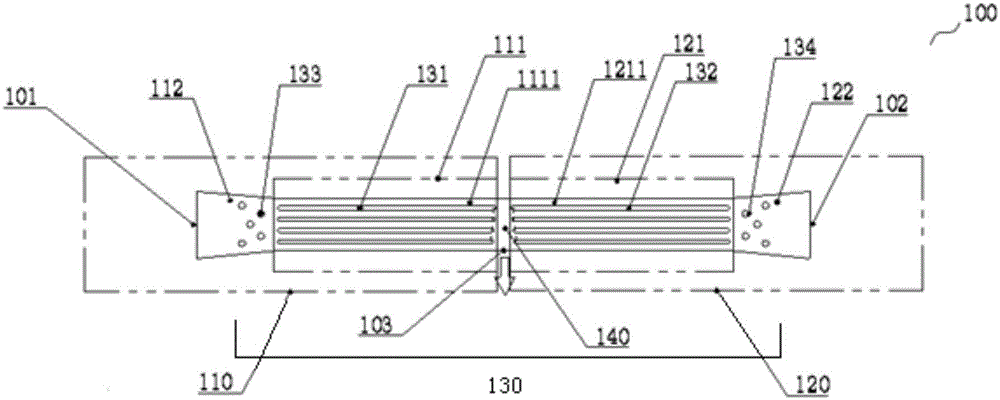

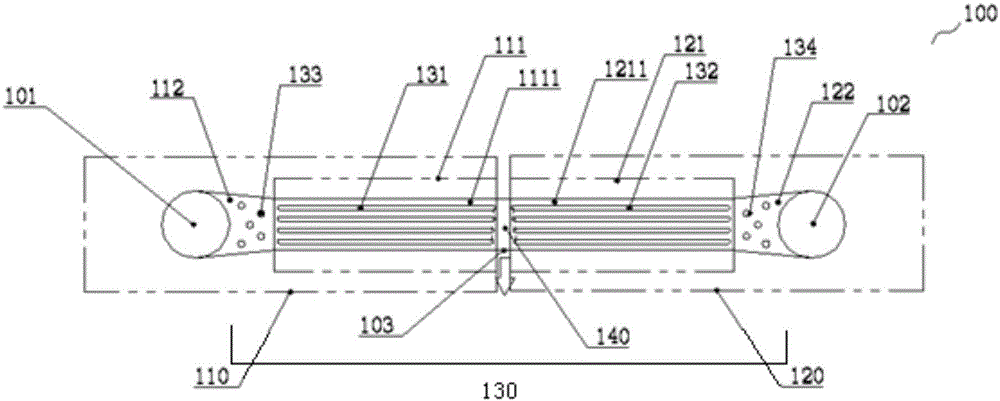

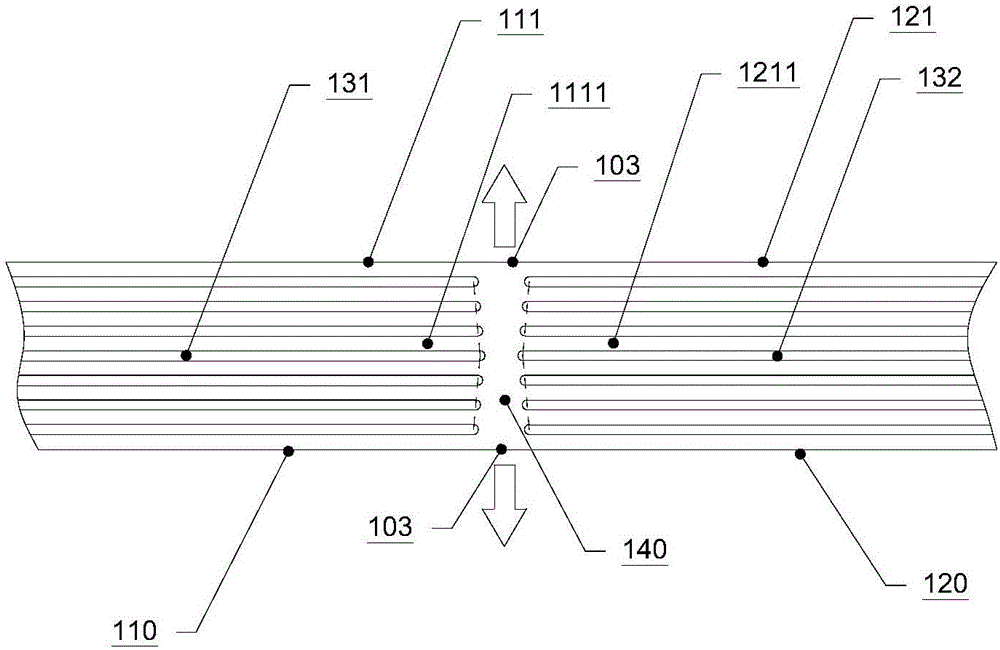

[0038] Such as figure 1 with figure 2 As shown, an embodiment of the present invention proposes a split-and-flush micro-reaction channel, which includes a reaction body 100 with a first inlet 101 at one end, a second inlet 102 at the other end, and a fluid outlet 103 between them.

[0039] Wherein, between the first inlet 101 and the outlet 103 is a first flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com