DCS control system used for amination workshop section in methyl cyclopentenolone production line

A technology of methylcyclopentenolone and production line amine, applied in the field of DCS control system in the amination section of methylcyclopentenolone production line, can solve the problems of low product yield, incomplete reaction, instability, etc., and achieve The reaction process is stable, the reaction temperature is guaranteed, and the effect of eliminating human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

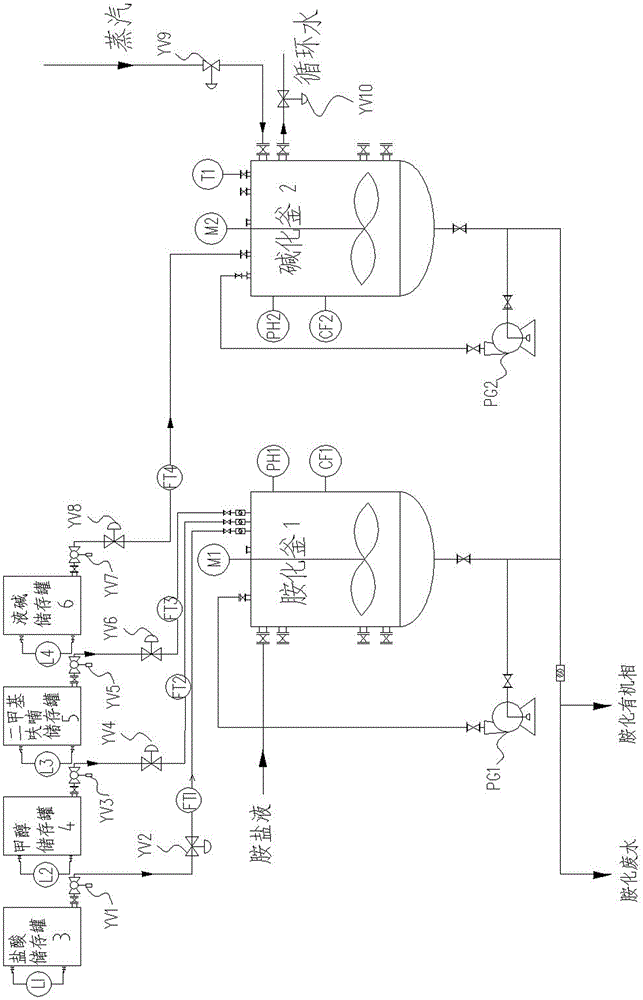

[0022] Such as figure 1 As shown, the present invention provides a DCS control system in the amination section of the methylcyclopentenolone production line, the outlets of the hydrochloric acid storage tank 3, the methanol storage tank 4 and the dimethylfuran storage tank 5 are respectively connected to the inlet of the amination kettle 1, The outlet of the liquid caustic soda storage tank 6 is connected to the inlet of the alkalization kettle 2, the amination kettle 1 and the alkalization kettle 2 form a circulation system through the first circulation pump PG1 and the second circulation pump PG2, and the amination kettle 1 and the alkalization kettle 2 The interlayer of the kettle wall is connected to the steam and circulating water system. The connecting pipe between the hydrochloric acid storage tank 3 and the amination kettle 1 is sequentially provided with a hydrochloric acid shut-off valve YV1 and a hydrochloric acid drip valve YV2, and a methanol storage tank 4 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com