Method for harmlessly treating electroplating sludge

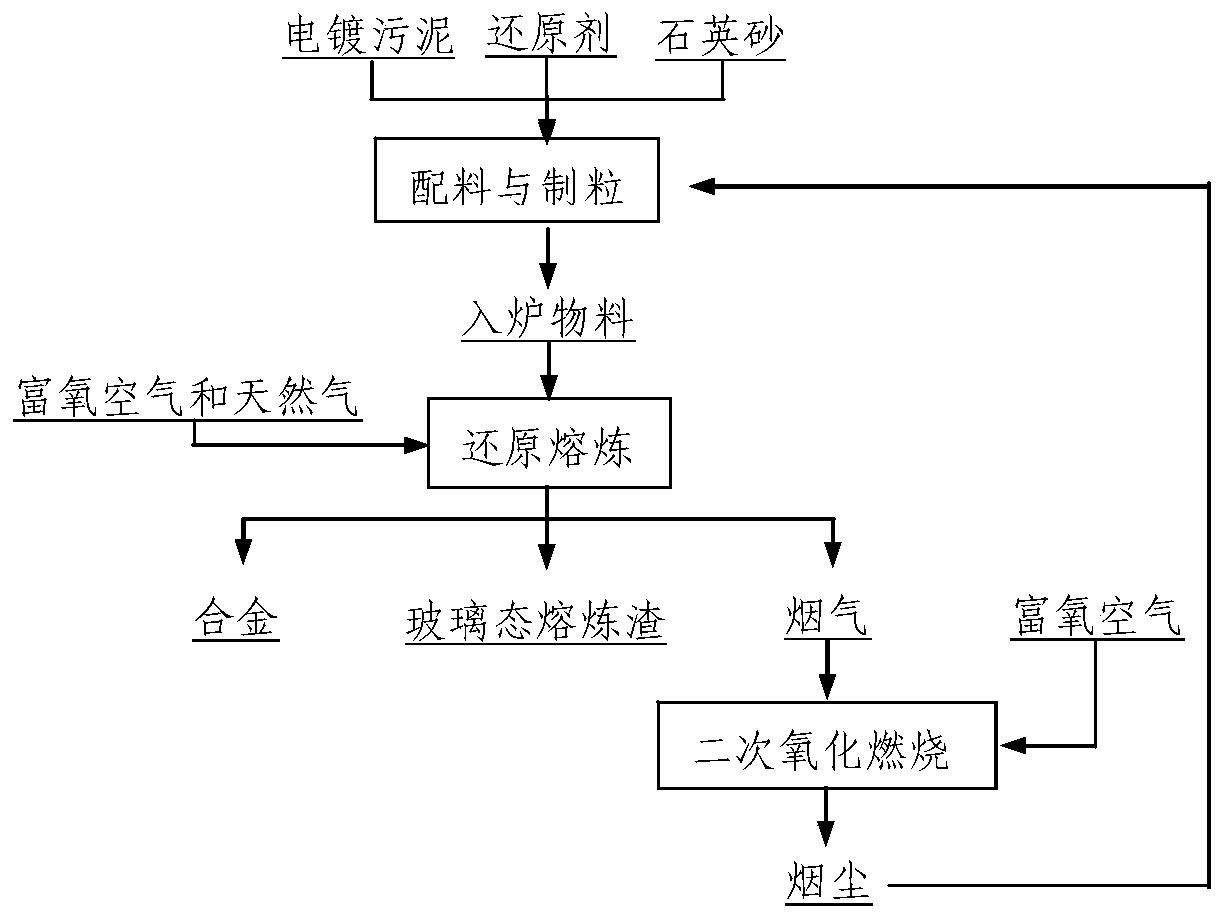

A technology of electroplating sludge and smelting slag, which is applied in the direction of cement production and process efficiency improvement, which can solve the problems of high processing cost and achieve the effects of maintaining reaction temperature, short processing time and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

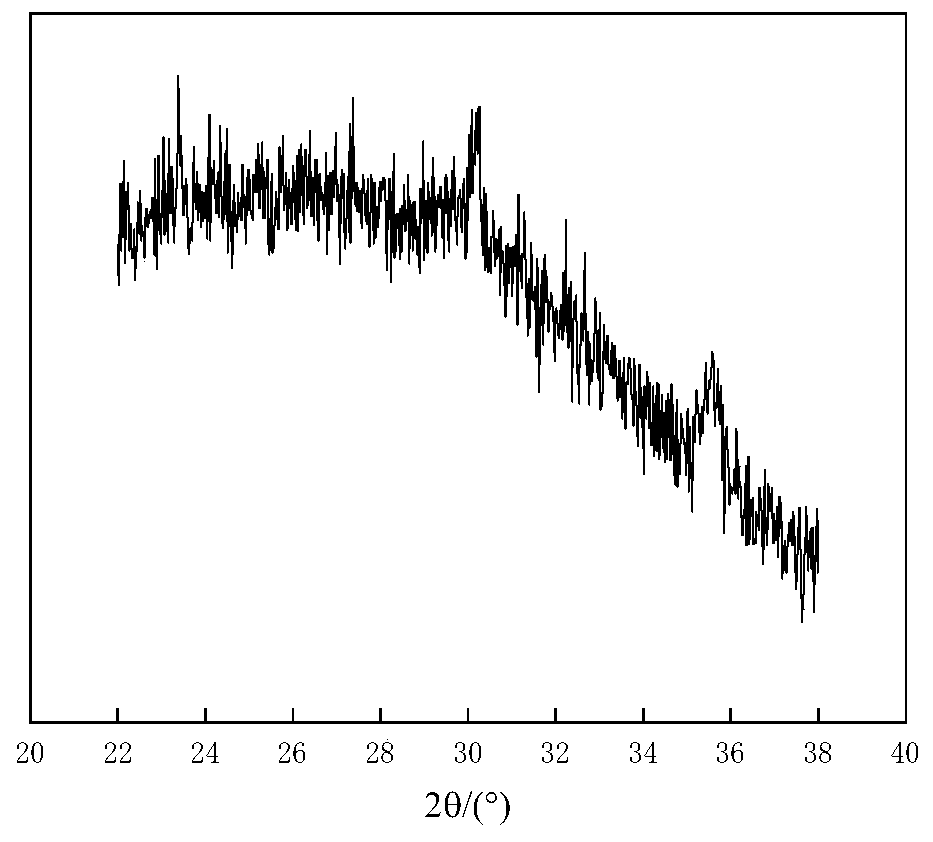

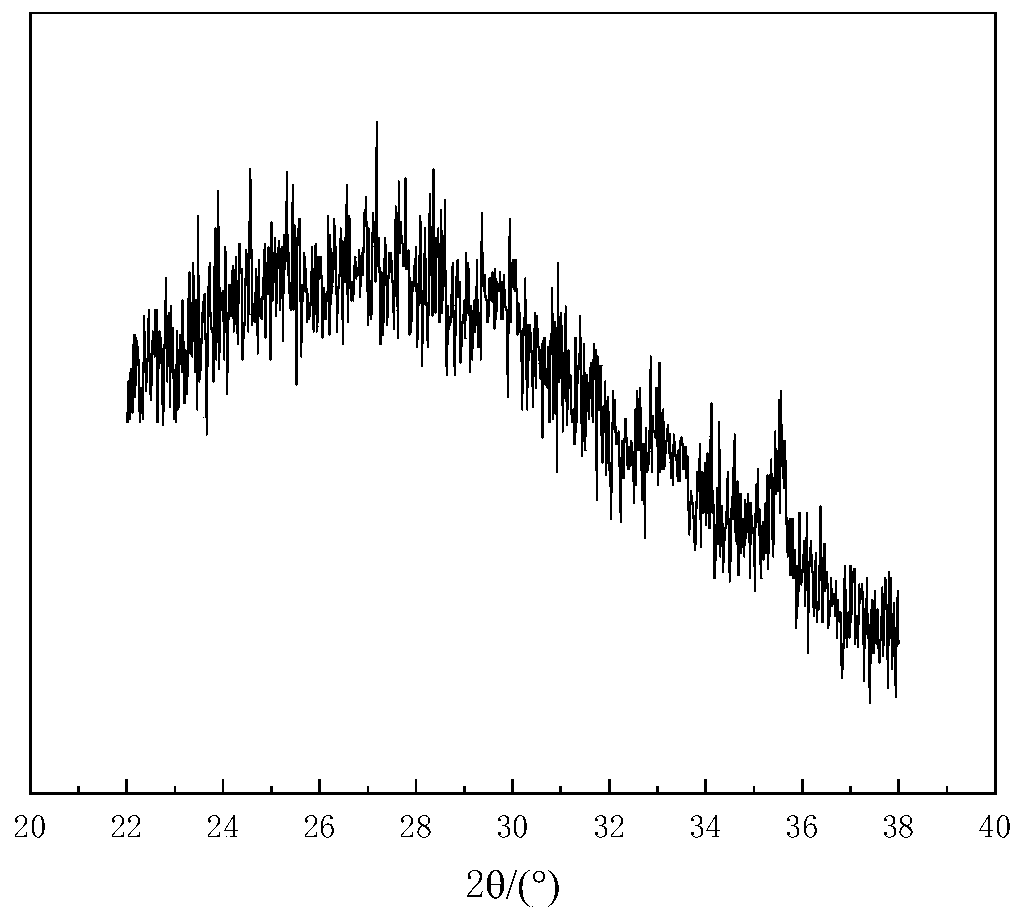

Image

Examples

Embodiment 1

[0033] Electroplating sludge composition: Fe 18.23%, Si 3.02%, Al 4.11%, Ca 7.65%, Ba 0.34%, Cr 4.22%, Cu 6.95%, Ni 2.71%, Pb 0.82%, Zn 7.54%.

[0034] Coke, whose carbon content is 82.21%; industrial oxygen, whose volume percentage concentration of oxygen is ≥99%; quartz sand, whose SiO 2 The content is 91.59%; natural gas, its CH 4 Content ≥ 85%.

[0035] The electroplating sludge, quartz sand, and coke are weighed and batched, and the added quartz sand is controlled to meet the initial requirements of the smelting slag type as FeO and SiO 2 The mass ratio is 1.2:1, and the quality of the coke is controlled to be 20% of the mass of the electroplating sludge; then, the electroplating sludge, quartz sand, and coke are added to the granulator for mixing and granulation, and the particle size of the furnace material after mixing is It is 8-20cm long and has a water content of 6%.

[0036] Add the granulated materials into the melting furnace, control the melting temperature a...

Embodiment 2

[0046] Main components of electroplating sludge: Fe 16.45%, Si 3.45%, Al 4.42%, Ca 7.25%, Ba 0.35%, Cr 4.65%, Cu 7.25%, Ni 2.21%, Pb 0.83%, Zn 8.25%

[0047] Pulverized coal, whose carbon content is 72.32%; industrial oxygen, whose volume percentage concentration of oxygen is ≥ 99%, and SiO of quartz sand 2 The content is 92.33%; natural gas, its CH 4 Content ≥ 85%. .

[0048] The electroplating sludge, quartz sand, and pulverized coal are weighed and batched, and the added quartz sand is controlled to meet the initial requirements of the smelting slag type as FeO and SiO 2 The mass ratio is 1.8:1, and the quality of pulverized coal is controlled to be 30% of the mass of the electroplating sludge; then, the electroplating sludge, quartz sand, and pulverized coal are added to the granulator for mixing and granulation, and the mixed pulverized coal is put into the furnace The particle size of the material is 6-25mm, and the water content is 9%.

[0049] Add the granulated ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com