A kind of bi-bioi/tna composite material and its application

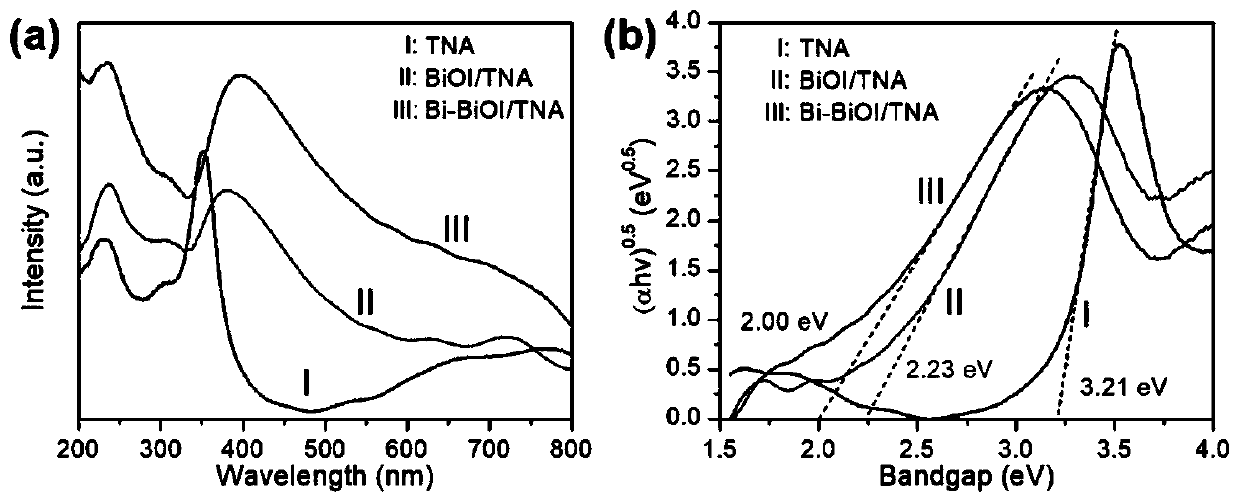

A composite material, reactor technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, energy input, etc., can solve the problems affecting the chemical stability of BiOI, instability limit, poor conductivity, etc., and achieve good photoelectrochemical performance. , avoid exchange, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

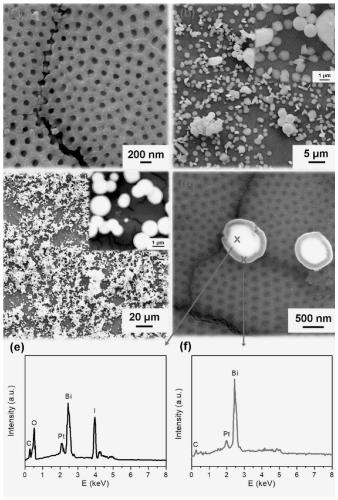

[0039] Preparation of S1 and TNA

[0040] The preparation of TNA adopts two-step anodic oxidation method, and the specific steps are as follows:

[0041] 1. Pretreatment: Cut the 0.1mm titanium sheet into small pieces of 50mm×30mm, polish it with sandpaper until there are no obvious scratches on the surface, ultrasonically clean it in ethanol, acetone and distilled water for 10 minutes each, and HF, concentrated HNO 3 Prepare a chemical polishing solution with distilled water at a volume ratio of 1:4:5, soak the titanium sheet in the polishing solution until no obvious bubbles are produced, and finally wash it with deionized water and dry it for later use;

[0042] 2. Preparation of TNA by two-step anodic oxidation method: prepare NH with a mass fraction of 0.5% 4The ethylene glycol-water solution of F is used as the electrolyte, the volume ratio of ethylene glycol and water is 49:1, the titanium sheet is used as the anode, and the platinum sheet is used as the cathode for an...

Embodiment 2

[0048] The difference with embodiment 1 is:

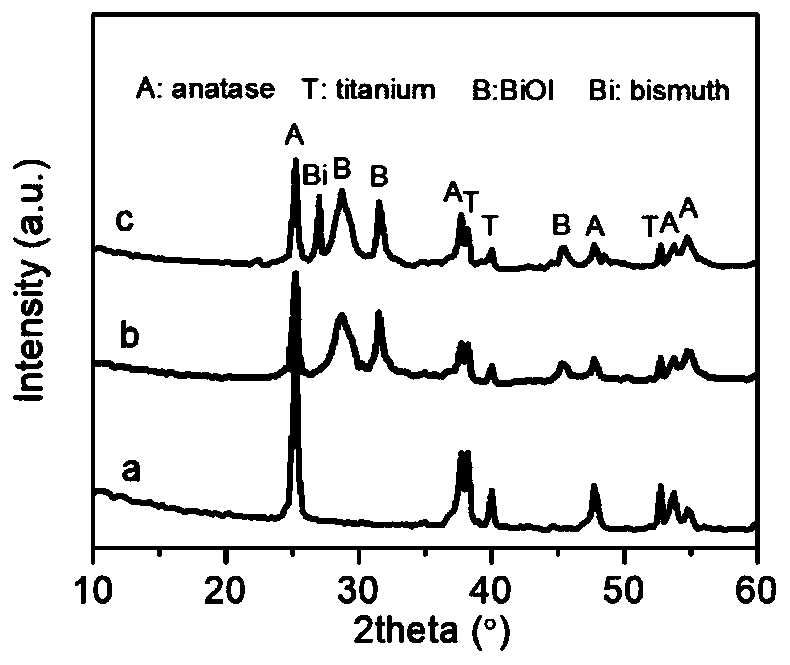

[0049] S3. Preparation of Bi-BiOI / TNA

[0050] Dissolve 8 mmol of glucose in 40 mL of ethylene glycol and transfer it to a 50 mL autoclave with a polytetrafluoroethylene liner. The BiOI / TNA sample is leaned against the inner wall of the autoclave at a certain angle, and the 2 / 3 of it was submerged in the glucose solution, heated at 140°C for 1 hour, and cooled naturally to room temperature after completion. The prepared BiOI / TNA samples were taken out and washed alternately with ethanol and water three times respectively, and dried overnight in an oven at 80°C.

Embodiment 3

[0052] The difference with embodiment 1 is:

[0053] S3. Preparation of Bi-BiOI / TNA

[0054] Dissolve 8 mmol of glucose in 40 mL of ethylene glycol and transfer it to a 50 mL autoclave with a polytetrafluoroethylene liner. The BiOI / TNA sample is leaned against the inner wall of the autoclave at a certain angle, and the 2 / 3 of it was submerged in the glucose solution, heated at 180°C for 1 hour, and naturally cooled to room temperature after completion. The prepared BiOI / TNA samples were taken out and washed alternately with ethanol and water three times respectively, and dried overnight in an oven at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com