Zero-halogen low-smoke flame-retardant sheath material used for photovoltaic cable and production method and application thereof

A photovoltaic cable, low-smoke and flame-retardant technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor comprehensive performance, achieve excellent performance such as oil resistance, improve electrical and mechanical properties, and enhance interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

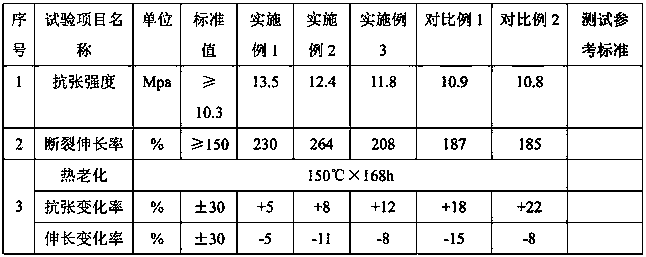

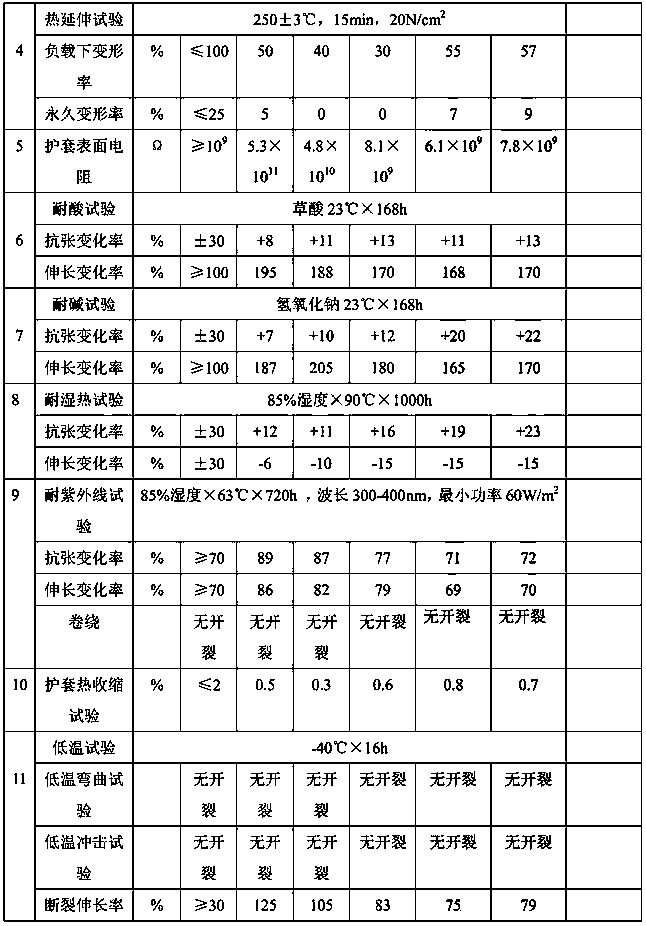

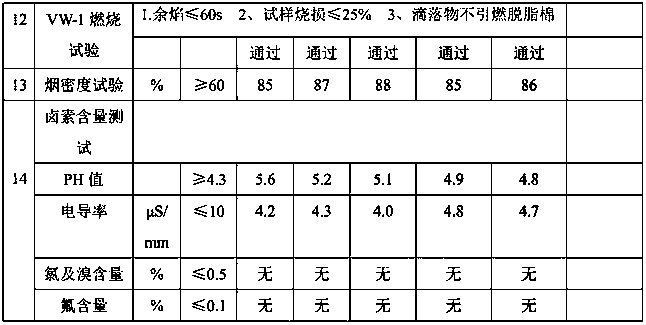

Examples

Embodiment 2

[0077] In Example 2, the working temperature of each zone of the twin-screw extruder is: 100°C in the first zone, 110°C in the second zone, 120°C in the third zone, 125°C in the fourth zone, 130°C in the fifth zone, and 140°C in the sixth zone. ℃, 150℃ in the seventh zone, 160℃ in the eighth zone;

[0078] The working temperature of each zone of the single-screw extruder is: the first zone is 120°C, the second zone is 130°C, the third zone is 140°C, and the fourth zone is 150°C;

[0079] The working temperature of each zone of the extruder is: the first zone is 120°C, the second zone is 130°C, the third zone is 135°C, the fourth zone is 145°C, the fifth zone is 150°C, and the sixth zone is 160°C.

Embodiment 3

[0080] In Example 3, the working temperature of each zone of the twin-screw extruder is: 105°C in the first zone, 115°C in the second zone, 123°C in the third zone, 127°C in the fourth zone, 132°C in the fifth zone, and 143°C in the sixth zone. ℃, 152℃ in the seventh zone, 162℃ in the eighth zone;

[0081] The working temperature of each zone of the single-screw extruder is: the first zone is 125°C, the second zone is 135°C, the third zone is 145°C, and the fourth zone is 153°C;

[0082] The working temperature of each zone of the extruder is: the first zone is 125°C, the second zone is 133°C, the third zone is 136°C, the fourth zone is 146°C, the fifth zone is 153°C, and the sixth zone is 163°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com