A device and method for removing organic impurities in by-product sodium chloride salt

A technology for by-product sodium chloride and sodium chloride salt is applied in the field of devices for removing organic impurities in by-product sodium chloride salt, which can solve the problems of carbonization equipment sticking, less impurity content, single treatment, etc., and achieve thermal efficiency Use high, solve nozzle clogging, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

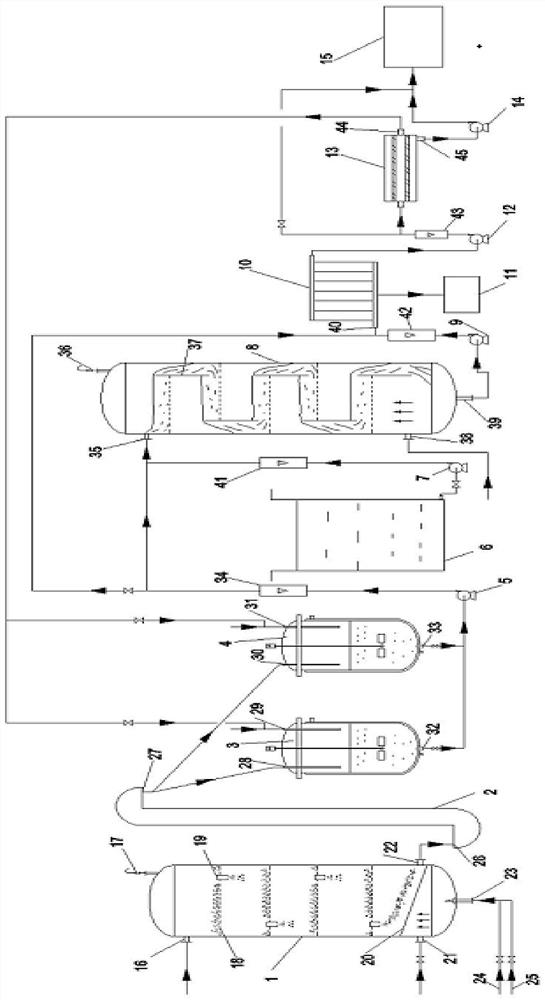

Embodiment 1

[0068] The high-temperature oxidation reactor 1 has a diameter of 1 m and a total height of 15 m. The number of layers of sieve plates 18 is 18, and the layer spacing is 0.6 m; 4 burners 23 are installed on the device wall from the 5th floor to the 8th floor, 1 burner on every floor. The volume of the dissolution kettle A3 and the dissolution kettle B4 is 10m 3 . The liquid-phase deep oxidation tower 8 has a diameter of 1.8m and a total height of 15m. It is in the form of multi-layer sieve plate bubbling gas-liquid contact, the number of gas-liquid contact layers is 12, and the layer spacing is 1.0m. Board 0.5m. The average pore size of the nanofiltration membrane of the fine filter 13 is 1.2nm.

[0069] Open the valves of the air inlet pipe 24 and the gas inlet pipe 25 of the burner 23, and ignite the burner 23 at the same time. When the hot spot temperature in the high temperature oxidation reactor 1 reaches 300 ° C, the total carbon content TOC will be 1400 mg based on s...

Embodiment 2

[0073] The diameter of the high temperature oxidation reactor 1 is 1m, the total height is 12m, the number of layers of the sieve plate 18 is 16, and the layer spacing is 0.55m; 4 burners 23 are installed on the device wall from the 5th floor to the 8th floor, 1 burner on every floor. The volume of the dissolution kettle A3 and the dissolution kettle B4 is 10m 3 . The liquid phase deep oxidation tower 8 has a diameter of 1.6m and a total height of 14m. It is in the form of multi-layer sieve plate bubbling gas-liquid contact, the number of gas-liquid contact layers is 14, and the layer spacing is 0.8m. Board 0.45m. The average pore size of the nanofiltration membrane of the fine filter 13 is 1.6 nm.

[0074] Open the valves of the air inlet pipe 24 and the gas inlet pipe 25 of the burner 23, and ignite the burner 23 at the same time. When the temperature of the hot spot in the high temperature oxidation reactor 1 reaches 300 ° C, the total carbon content TOC will be 1500 mg ...

Embodiment 3

[0078] The diameter of the high temperature oxidation reactor 1 is 1m, the total height is 12m, the number of layers of the sieve plate 18 is 16, and the layer spacing is 0.5m; Six burners 23 are installed on the walls of the 5th to 8th floors, 2 burners are respectively installed on the 5th and 7th floors, and 1 burner is installed on the 6th and 8th floors. The volume of the dissolution kettle A3 and the dissolution kettle B4 is 10m 3 . The liquid-phase deep oxidation tower 8 has a diameter of 1.6m and a total height of 16m. It is in the form of packed gas-liquid contact, and the height of the packed layer is 10m. The average pore diameter of the nanofiltration membrane of the fine filter 13 is 1.5 nm.

[0079] Open the valves of the air inlet pipe 24 and the gas inlet pipe 25 of the burner 23, and ignite the burner 23 at the same time. When the hot spot temperature in the high temperature oxidation reactor 1 reaches 300 ° C, the total carbon content TOC will be 1800 mg base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com