Forming method of high-precision hyperboloid titanium alloy cylinder

A titanium alloy and hyperboloid technology, which is applied in the forming field of high-precision hyperboloid titanium alloy cylinder, can solve the problems of difficult repair, high welding cost, and large number of welds, so as to reduce the number of welds and increase the yield , the effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

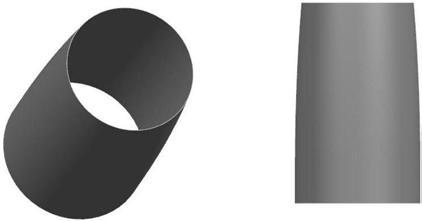

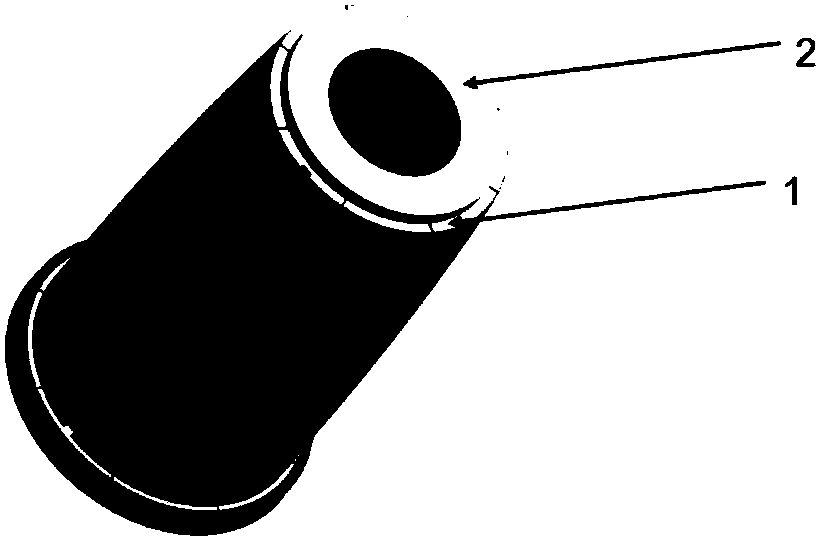

[0028] combine Figure 1-3 Describe this embodiment, this embodiment provides a kind of forming method of high-precision hyperboloid titanium alloy cylinder, and this forming method is to carry out according to the following steps:

[0029] 1) Cut the titanium alloy sheet material according to the planar expansion size of the cylinder, roll the cut titanium alloy sheet material into a cylindrical shape through the rolling machine equipment, grind the butt-to-weld area of the cylindrical part, pickle the area to be welded, and pass through The cylindrical parts after grinding and pickling are placed on the automatic argon arc welding machine for argon arc welding to obtain the rolled and welded cylindrical parts;

[0030] 2) Place the cylindrical part obtained in step 1) on the outside of the expansion flap (1) of the stress relaxation forming tool, and then put the expansion core 2 into the expansion flap 1, and the fit is intact;

[0031] 3) Put the cylindrical part, expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com