Method for preparing silicon-carbon composite material by molten salt electrolysis

A technology of silicon-carbon composite materials and molten salt electrolysis, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve problems such as pulverization, and achieve the effect of good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] In this embodiment, the method for preparing a silicon-carbon composite material by molten salt electrolysis, the specific steps are as follows:

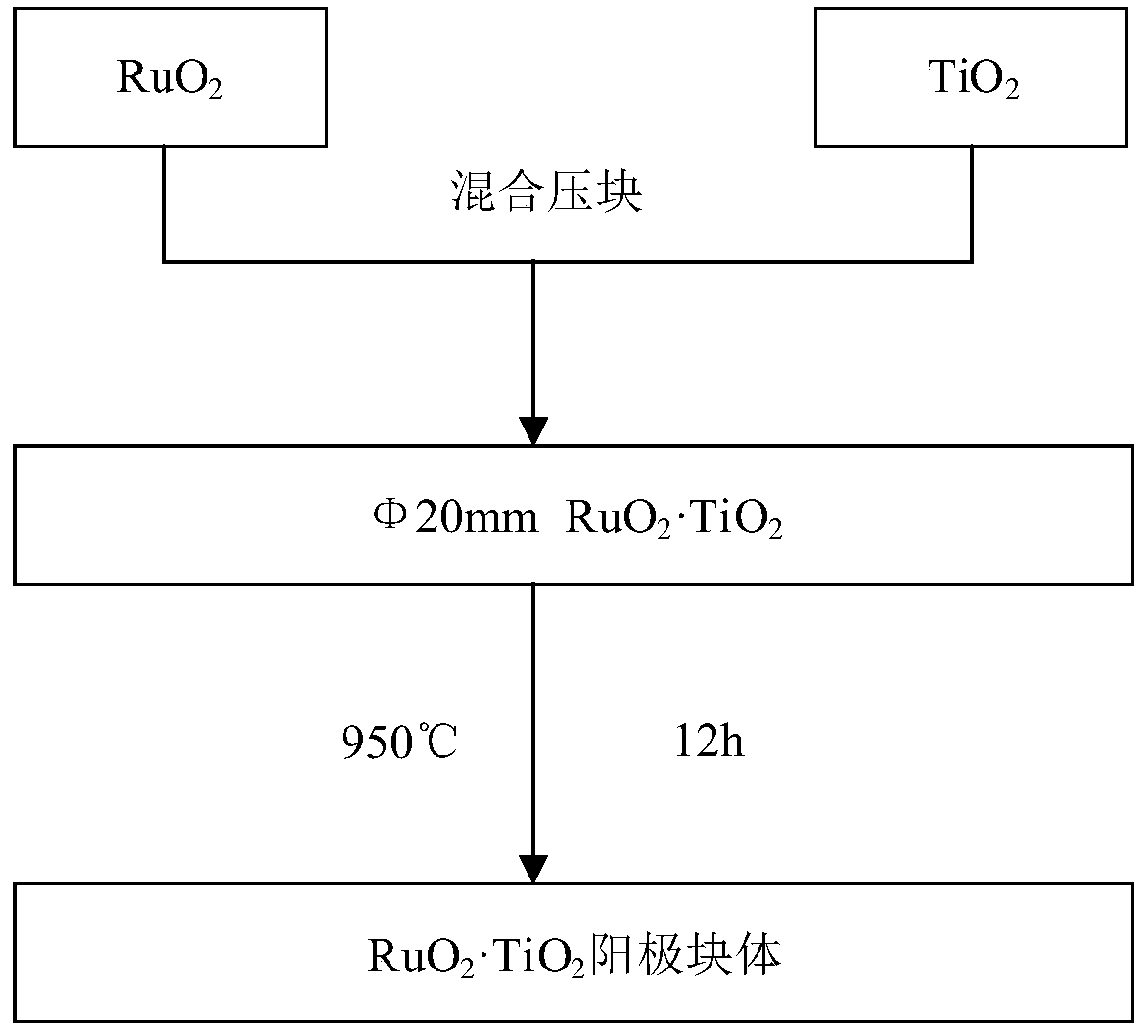

[0013] In the first step, an oxide inert anode is used as the anode of the electrolytic cell, and graphite is used as the cathode of the electrolytic cell.

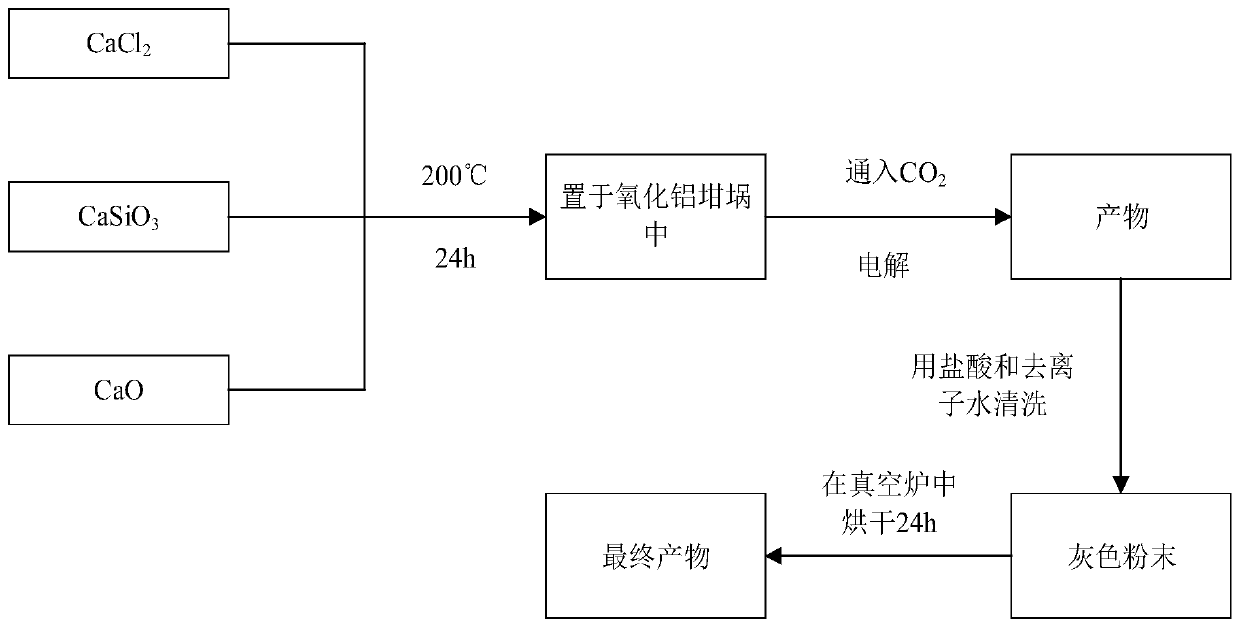

[0014] In the second step, the CaCl 2 , CaSiO 3 and CaO were first added to a cylindrical alumina crucible and heated to 200 ° C for 24 hours to remove moisture, CaCl 2 -CaSiO 3 -The mass ratio of the three components in the CaO mixture to CaCl 2 : CaSiO 3 : CaO=25~40:1.5:0.5, CaSiO 3 The ratio of CaO and CaO is preferably 3:1, CaCl 2 The amount can be adjusted according to the volume of the crucible and the liquid level of the molten salt.

[0015] The third step is to heat the crucible, CaCl 2 , CaSiO 3 Melt with CaO to form an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com