A kind of water-based anticorrosion primer and preparation method thereof

An anti-corrosion primer, water-based technology, applied in the field of coatings, can solve the problems of coating defects, performance degradation, no longer providing protection, etc., to achieve the effect of improving anti-settling, improving long-term anti-corrosion performance, and increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

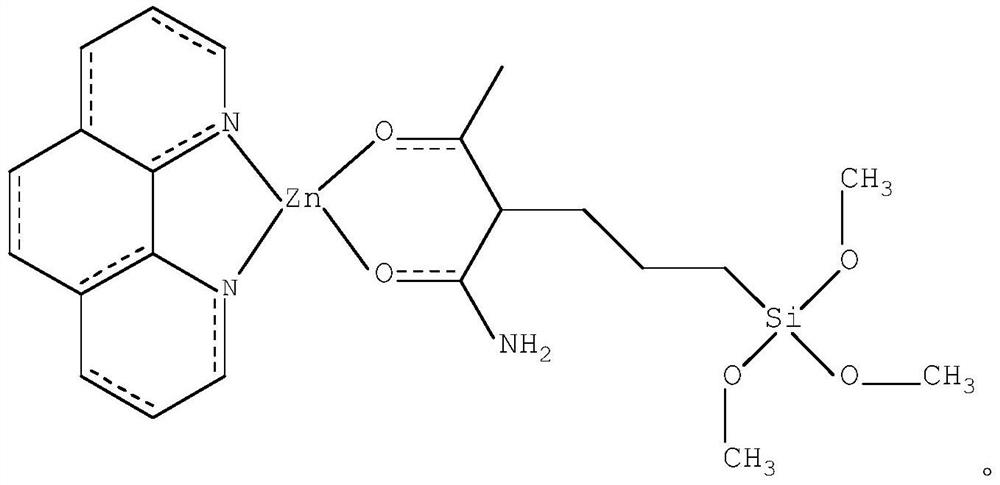

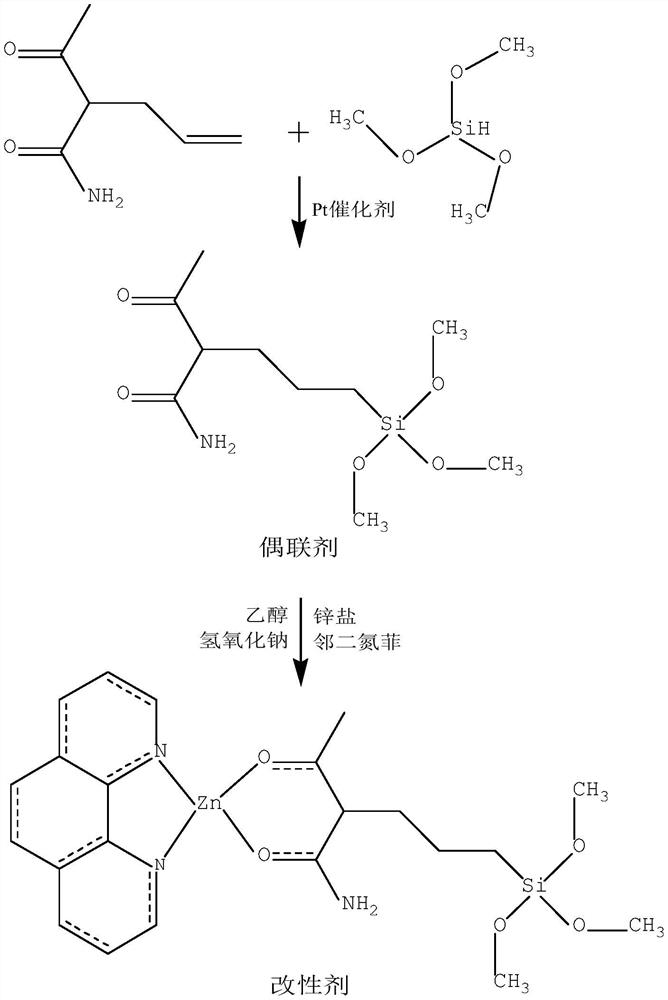

Image

Examples

Embodiment 1

[0028] The water-based anti-corrosion primer is composed of the following components in parts by weight: 85 parts of water-based epoxy resin, 20 parts of modified nano-silica, 1.5 parts of BYK-012, 0.3 parts of BYK-420, 5 parts of BYK-4510, 20 parts of amine, 25 parts of deionized water.

[0029] The preparation method of the modified nano silicon dioxide is as follows: dissolving the modifying agent in the DMF aqueous solution, adding the nano silicon dioxide, stirring and dispersing for 0.5h, filtering, washing and drying. Wherein, the volume ratio of DMF to water in the DMF aqueous solution is 7:1.

[0030] The preparation method of waterborne anticorrosion primer, comprises the steps:

[0031] (1) Weigh each component in proportion, add the modified nano silicon dioxide and defoamer to half of the deionized water, stir evenly, and grind until the fineness is less than 30 μm;

[0032] (2) Add water-based epoxy resin, rheology modifier, adhesion promoter, curing agent and ...

Embodiment 2

[0034] The water-based anti-corrosion primer is composed of the following components in parts by weight: 80 parts of water-based epoxy resin, 15 parts of modified nano-silica, 1 part of BYK-018, 0.1 part of BYK-410, 3 parts of BYK-4510, diethyl 15 parts of aminopropylamine, 20 parts of deionized water.

[0035] The preparation method of the modified nano silicon dioxide is as follows: dissolving the modifying agent in the DMF aqueous solution, adding the nano silicon dioxide, stirring and dispersing for 0.8 hours, filtering, washing and drying. Wherein, the volume ratio of DMF to water in the DMF aqueous solution is 6:1.

[0036] The preparation method of waterborne anticorrosion primer, comprises the steps:

[0037] (1) Weigh each component in proportion, add the modified nano silicon dioxide and defoamer to half of the deionized water, stir evenly, and grind until the fineness is less than 30 μm;

[0038] (2) Add water-based epoxy resin, rheology modifier, adhesion promote...

Embodiment 3

[0040] The water-based anti-corrosion primer is composed of the following components in parts by weight: 90 parts of water-based epoxy resin, 25 parts of modified nano-silica, 2 parts of BYK-022, 0.5 parts of BYK-411, 8 parts of BYK-4511, two parts of 25 parts of ethyltriamine, 30 parts of deionized water.

[0041] The preparation method of the modified nano silicon dioxide is as follows: dissolving the modifying agent in the DMF aqueous solution, adding the nano silicon dioxide, stirring and dispersing for 1 hour, filtering, washing and drying. Wherein, the volume ratio of DMF to water in the DMF aqueous solution is 8:1.

[0042] The preparation method of waterborne anticorrosion primer, comprises the steps:

[0043] (1) Weigh each component in proportion, add the modified nano silicon dioxide and defoamer to half of the deionized water, stir evenly, and grind until the fineness is less than 30 μm;

[0044] (2) Add water-based epoxy resin, rheology modifier, adhesion promot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com